In the rapidly evolving landscape of energy storage, lithium-ion batteries stand at the forefront, propelling innovations in electric vehicles and renewable energy systems worldwide. A critical component underpinning the performance of these batteries is ethyl methyl carbonate (EMC), a solvent that accounts for nearly a third of the conventional electrolyte formulations. EMC’s unique chemical profile—balancing high solubility, thermal stability, and safety—makes it a cornerstone in battery manufacturing. Yet, despite its importance, the synthesis of EMC has long been plagued by industrial inefficiencies and chemical challenges that have hindered scalability and sustainability.

In a groundbreaking advancement, a collaborative research team hailing from Qingyuan Innovation Laboratory, East China Engineering Science and Technology Co. Ltd., and Fuzhou University has unveiled a novel catalyst system that adeptly addresses these entrenched challenges. Central to their innovation is [DBU⁺][IM⁻]@UiO-66, an acid-base bifunctional catalyst that integrates the complementary catalytic properties within a single, structurally robust material. This synergy not only enhances reaction efficiency but also mitigates side reactions that have traditionally hampered product yield and purity.

.adsslot_TArILwZDQl{ width:728px !important; height:90px !important; }

@media (max-width:1199px) { .adsslot_TArILwZDQl{ width:468px !important; height:60px !important; } }

@media (max-width:767px) { .adsslot_TArILwZDQl{ width:320px !important; height:50px !important; } }

ADVERTISEMENT

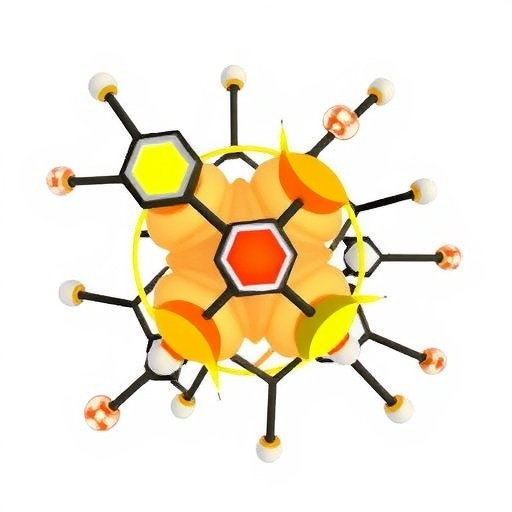

UiO-66, a zirconium-based metal-organic framework (MOF), forms the catalyst’s backbone. Renowned for its exceptional porosity, high surface area, and remarkable chemical stability, UiO-66 serves as an ideal scaffold for hosting catalytic active sites. Notably, deliberate defect engineering within UiO-66 introduces acidic sites by creating coordinatively unsaturated zirconium centers. These acidic moieties are pivotal in activating the carbonyl functional groups of DMC and DEC, thereby facilitating substrate adsorption and initial reaction steps.

Complementing these acidic sites, the team immobilized an ionic liquid, [DBU⁺][IM⁻], within the porous architecture of UiO-66. The ionic liquid contributes potent basic active sites, primarily due to the strong nucleophilicity of the 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU) cation paired with the imidazolide anion. This duality of acid and base functions operating in close proximity within the same catalyst enhances the formation of reactive intermediates crucial for efficient transesterification. Altogether, the catalyst promotes a concerted mechanistic pathway, accelerating EMC production while suppressing unwanted side processes.

Laboratory evaluations underscore the efficacy of this approach. Under optimized conditions—specifically, a reaction temperature of 100°C maintained over five hours and a catalyst loading of 8 weight percent relative to DMC—the catalyst achieved an impressive EMC yield of 62% coupled with an almost unparalleled selectivity of 99.5%. This near-quantitative selectivity translates to minimal generation of byproducts, an outcome highly desirable for industrial sustainability and downstream processing.

Beyond catalytic performance, stability and reusability are regarded as essential parameters for commercial feasibility. The [DBU⁺][IM⁻]@UiO-66 catalyst demonstrated commendable resilience over repeated reaction cycles. Even after six successive uses, catalytic activity diminished only marginally, with conversion efficiencies tapering minimally from 62% to 58.9%. This sustained performance is attributed to the intrinsic durability of the UiO-66 framework, which effectively preserves the immobilized ionic liquid components, preventing leaching and structural degradation.

The synergy observed in the acid-base catalysis embodied by [DBU⁺][IM⁻]@UiO-66 represents a strategic departure from conventional single-site catalysts. By orchestrating cooperative interactions between acidic and basic sites within a spatially confined environment, the research offers a paradigm shift in the microscopic understanding and macroscopic control of organic transesterification reactions. This advancement not only has direct implications for battery-grade EMC synthesis but also paves the way for designing multifaceted catalysts tailored for precision chemical manufacturing.

Zhaoyang Qi, a corresponding author of the study, emphasized the significance of this breakthrough: “Our catalyst transcends the conventional compromise typically encountered in EMC synthesis. The integration of acid and base active sites within a singular, reusable architecture eliminates undesirable side reactions, elevates efficiency, and crucially aligns with scalable industrial protocols.” Such statements highlight the broader impact beyond pure chemistry, touching on economic and environmental imperatives that surround the transition toward cleaner energy vectors.

Aligned with global trends aimed at decarbonization and energy storage enhancement, this catalytic innovation arrives at a crucial juncture. The ability to reliably produce high-quality EMC not only facilitates higher-performing lithium-ion batteries but also strengthens supply chains critical for electric vehicles and renewable energy grid integration. Moreover, the use of MOF-based catalysts functionalized with ionic liquids exemplifies the versatile, cutting-edge materials science approaches necessary to meet these demands.

This research is distinguished not just by its experimental results but by the strategic design philosophy that underpins it. The meticulous engineering of defect sites in UiO-66 to create acidic centers, combined with the precise immobilization of ionic liquids to furnish base sites, illustrates a sophisticated level of materials tailoring—a trend increasingly defining modern catalysis. Future avenues may explore expanding such bifunctional catalysts toward other industrially relevant reactions, underscoring the broader applicability of these findings.

Given the exceptional catalytic performance and stability, prospects for industrial adoption appear promising. Nonetheless, further scale-up studies, process integration evaluations, and economic assessments remain essential to transition from laboratory proof-of-concept to commercial reality. These steps are anticipated to be facilitated by the catalyst’s compatibility with existing reactor configurations and the use of benign reaction conditions that minimize energy consumption and waste.

This work ultimately symbolizes a milestone in green chemical engineering, where molecular-level insights and materials innovation converge to solve pressing industrial challenges. The dual-site catalytic approach not only elevates the synthesis of a key battery electrolyte component but also exemplifies the direction of future research focused on sustainable, energy-efficient chemical production.

Subject of Research: Not applicable

Article Title: Transesterification of dimethyl carbonate and diethyl carbonate over [DBU+][IM-]@UiO-66: synergistic catalysis of acid-base active sites

News Publication Date: 28-May-2025

Web References: http://dx.doi.org/10.1016/j.gce.2025.05.007

Keywords: Chemistry, Polymer chemistry, Catalysis

Tags: catalytic reaction improvementschemical process optimizationeco-friendly manufacturing techniqueselectric vehicle battery technologyEnergy Storage Solutionsethyl methyl carbonate synthesisindustrial catalyst efficiencyinnovative bifunctional catalystlithium-ion battery productionrenewable energy systemssustainable battery materialstransesterification challenges