In the ever-evolving landscape of manufacturing technologies, Electrical Discharge Machining (EDM) has emerged as a pivotal player, particularly in the production of intricate geometries and precision components. A recent study conducted by researchers R. Nowicki and R. Świercz has delved into the nuanced world of EDM, specifically focusing on the surface texture properties that result from these processes when utilizing graphite electrodes of varying grain sizes. This exploration not only unveils the critical impacts of electrode material and configuration on surface finish quality but also raises intriguing implications for future manufacturing applications.

EDM operates on the principle of material removal through controlled electrical discharges, a technique that is especially advantageous in working with hard materials and complex shapes. The process involves creating repetitive sparks between an electrode and the workpiece, which effectively erodes the material of the latter. The introduction of negative polarity in the EDM process, as investigated in the study, alters the dynamics of these discharges and hence may significantly influence the resulting surface characteristics of machined parts.

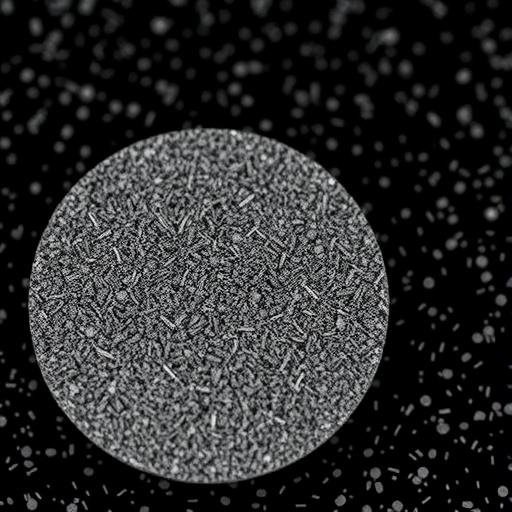

One focal point of the study is the comparative analysis of different graphite electrode grain sizes. Naturally, the grain size of the electrode material plays a crucial role in the efficiency and effectiveness of the EDM process. Coarser grains may offer various advantages, such as improved material removal rates and reduced wear of the electrodes, whereas finer grains tend to create smoother surface finishes. The researchers meticulously explored these dynamics, illuminating the critical balance engineers must strike when selecting electrode materials for specific applications.

The implications of using negative polarity in EDM are compelling. Traditionally, the polarity of the electrodes can substantially emerge as a factor in the performance of the machining process. When negative polarity is adopted, there is a shift in how electrical discharges interact with the workpiece and electrode. This study has sought to unravel these complex interactions in an effort to optimize the EDM process for various industrial applications, which rely heavily on surface quality and precision.

Surface texture is not merely a cosmetic consideration; it profoundly influences the functional attributes of machined components. Components with rough surfaces can exhibit poor wear resistance and lubrication characteristics, while those with finer finishes may demonstrate superior performance and longevity. Hence, understanding how different parameters impact surface texture is essential for manufacturers aiming to produce high-quality, durable components.

The research conducted by Nowicki and Świercz reveals a significant relationship between electrode grain size, polarity conditions, and the resultant surface properties after machining. Their findings indicate that utilizing electrodes with specific grain sizes can enhance or mitigate surface irregularities. This discovery offers a practical roadmap for engineers and manufacturers who strive for excellence in component fabrication and can lead to innovations in EDM technology tailored more closely to industry requirements.

As the demand for high precision and quality in component fabrication grows across numerous industries, including aerospace, automotive, and medical devices, the insights provided by this study are timely and critical. It also opens avenues for future research, posing questions about the optimization of other machining parameters, such as pulse duration and discharge energy, in combination with electrode attributes.

Moreover, this research has significant implications for the cost-effectiveness of the EDM process. The choice of electrode material and setting can drastically influence not only the quality of the surface finish but also the overall efficiency and productivity of the machining operation. In an industry where profit margins are often slim, the ability to make informed decisions based on empirical data and findings can be a game-changer for manufacturers.

Furthermore, the exploration of alternative materials and methods could lead to breakthroughs that further improve the EDM process, making it even more versatile for various applications. By establishing a clearer understanding of the interplay between electrode characteristics and machining conditions, the study provides a foundation for future innovations that can revolutionize how engineers approach surface finishing in EDM.

In conclusion, the research conducted by Nowicki and Świercz underscores the importance of material science in enhancing manufacturing practices. By bridging the gap between theoretical knowledge and practical application, they have provided invaluable insights that can facilitate advancements in EDM technology. As industries continue to embrace digital tools and smart manufacturing processes, such research will be essential in guiding the development of new techniques and technologies meant to meet the sophisticated demands of modern manufacturing.

In essence, with precise modifications to the parameters governing Electrical Discharge Machining, manufacturers can achieve unprecedented levels of surface finish quality. This relentless pursuit of perfection is not only a hallmark of engineering excellence but also a necessary step forward in maintaining competitiveness in an increasingly demanding market. As we move toward future manufacturing horizons, studies like this exemplify the innovative spirit that drives the industry to greater heights.

Subject of Research: Electrical Discharge Machining (EDM) with Graphite Electrodes

Article Title: The surface texture properties after electrical discharge machining with negative polarity using graphite electrodes of different grain sizes.

Article References:

Nowicki, R., Świercz, R. The surface texture properties after electrical discharge machining with negative polarity using graphite electrodes of different grain sizes.

Sci Rep (2025). https://doi.org/10.1038/s41598-025-33799-6

Image Credits: AI Generated

DOI:

Keywords: Electrical Discharge Machining, surface texture, graphite electrodes, negative polarity, manufacturing technology.

Tags: advantages of EDM for hard materialscomparative analysis of graphite electrodesEDM process parameters and outcomesElectrical Discharge Machining surface textureelectrode configuration and surface finishgraphite grain size effects on EDMimpact of electrode material on machiningintricate geometries in EDM applicationsmanufacturing technologies and precision componentsnegative polarity in EDM processstudy on EDM electrode grain sizesurface quality in electrical discharge machining