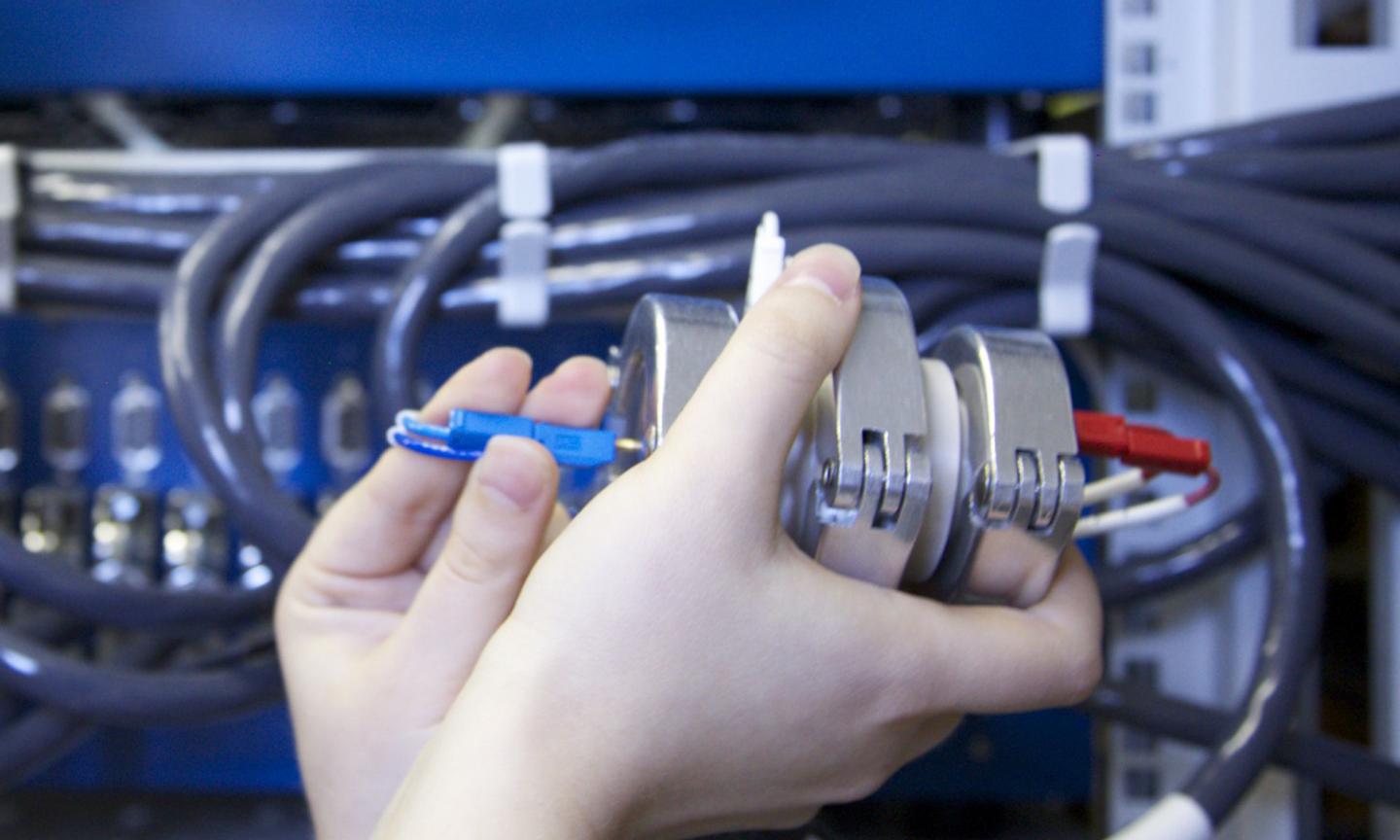

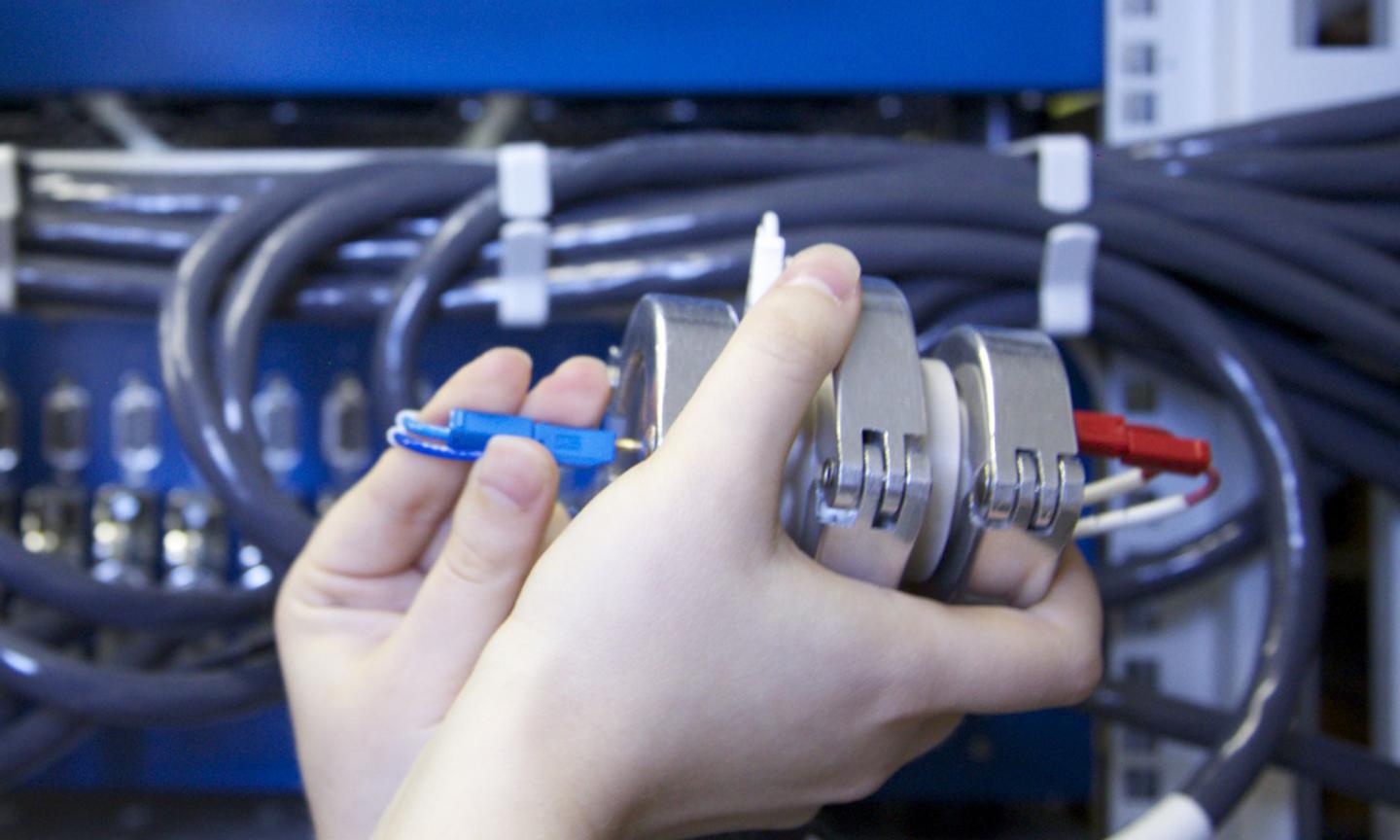

Credit: Daniil Itkis

Scientists from the Faculties of Materials Science and Chemistry, Lomonosov Moscow State University, are working on improvement of lithium-air batteries, which can significantly exceed the key parameters of lithium-ion systems. The research results are available in the article, published in the Journal of Physical Chemistry C.

Scientists and producers usually face a problem to elaborate batteries of new types: lighter but at the same time more powerful and with higher energy storage capacity. One of the possible ways to do that is to replace modern lithium-ion batteries by so called lithium-air batteries. Such batteries would be able to accumulate five times more power than usual lithium-ion ones. One area, where they could make revolution, is electric cars, which now use lithium-ion batteries.

Scientists from the Lomonosov Moscow State University have devoted their study to the processes of electrochemical oxygen reduction in a lithium-air battery. The lithium-air battery operates in the following way: when battery discharges, the negative electrode, represented by lithium foil, dissolves forming lithium ions, which move through the electrolyte layer to the positive electrode. The positive electrode is a porous carbon sponge wetted by the electrolyte. Atmospheric oxygen coming into a cell from the environment dissolves in electrolyte and reaches the carbon positive electrode. Right at the interface of carbon and electrolyte one of the key processes – electrochemical oxygen reduction – proceeds. Oxygen molecules receive electrons from the carbon material and after that connect with lithium ions. As a result, we get a battery discharge product, namely, solid lithium peroxide, which settles inside the pores in carbon. Peroxide, however, is formed not immediately. First, very active particles – superoxide anions – are produced. Only after some time these species are converted to a final product.

Lithium-ion battery operation is quite different. In contrast, there is no lithium metal in it: both in negative and positive electrodes lithium exists in the form of ions (here the name originates from). The specific energy of a lithium-ion battery achieved for today is about 220-240 W?h/kg (calculated per cell mass with battery case included). Active materials, which accommodate lithium ions, contributes more than half of the cell weight. The rest refers to electrolyte, current collectors, casing materials and various additives. As there is no need for an active materials for lithium ions hosting in a lithium-air battery, the battery mass is lower. For this reason, much higher specific energy can be acheived in such batteries.

Daniil Itkis, Ph.D. in Chemistry, a Senior Researcher at the Inorganic Chemistry Department of the Faculty of Chemistry, Lomonosov Moscow State University, who is one of the co-authors, says: "Elaboration of novel metal-air batteries with nonaqueous electrolytes and namely lithium-air power sources, after creating a lot of noise several years ago, has now reached a deadlock. It has turned out that oxygen reduction in such lithium-air batteries proceeds with many difficulties, through many stages and is accomplished by lots of side reactions. The desire, typical for many researchers and innovators, to provide the soonest commercialization of such batteries, which could exhibit much higher perfomance in comparison to lithium-ion ones, has failed due to the lack of deep understanding of the processes, taking place inside a battery."

At the moment it's impossible to recharge a lithium-air battery more than several times. After few recharge cycles the carbon positive electrode, where oxygen reduction and further reaction with lithium ions proceeds, becomes electrically passivated. It happens due to side reactions with intermediate species – superoxide anions. These particles are so active that provoke reactions of electrolyte and carbon electrode oxidation. In this process materials get damaged and an electrolyte is wasted for these side reactions. Search for sore spots in the carbon material, which suffer from such side processes, will help scientists to bring lithium-air batteries closer to practice and consequently transfer them from laboratory to scaled-up fabrication.

Previously, scientists from the Lomonosov Moscow State University in collaboration with American colleagues have found that oxygen reduction could proceed differently, depending on the peculiarities of the electrolyte used. Now Daniil Itkis' scientific team has shown that the mechanism of the reaction could vary also depending on the degree of the carbon electrode material imperfection. In their project scientists have compared how the process proceeds on different model graphitic electrodes. In their earlier work scientists assumed that an attack of superoxide anions on carbon materials started in places where there are defect sites in carbon. In the current study scientists have proved this hypothesis in the electrolytes often used in lithium-air battery research.

Daniil Itkis continues: "In general, the result is disappointing as there are no carbon materials without imperfections in reality. It means that we should look for ways which can help to shift the region where the reaction proceeds, farther from the carbon material. Now we are actively thinking this matter over."

Daniil Itkis adds: "It's difficult to say now whether lithium-air batteries will be cheaper or more expensive than lithium-ion ones. We could assume that they will be cheaper. But the problem is often hidden in details. It can turn out that in order to reach rechargeability we'd have to add some very expensive additives. I could say that we won't get any prototypes till 2020-2025".

###

Media Contact

Vladimir Koryagin

[email protected]

http://www.msu.ru

############

Story Source: Materials provided by Scienmag