Sometimes, in creating an alloy out of multiple metals, defects and structural instability can occur in the material. Now, researchers at the University of Pittsburgh Swanson School of Engineering are harnessing those imperfections to make the material stronger while retaining its flexibility.

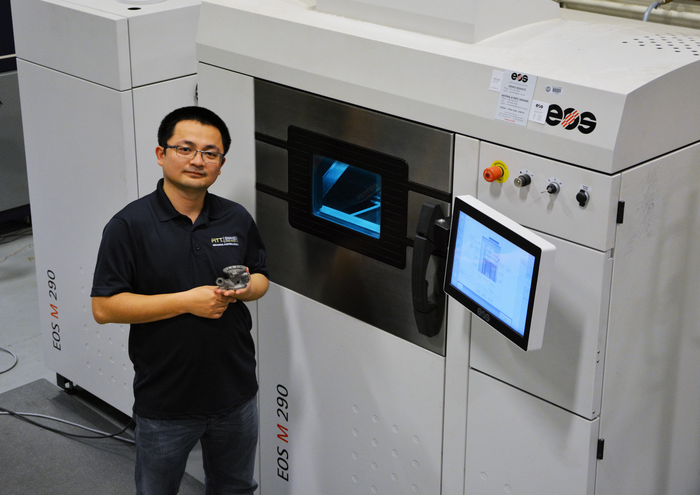

Credit: University of Pittsburgh

Sometimes, in creating an alloy out of multiple metals, defects and structural instability can occur in the material. Now, researchers at the University of Pittsburgh Swanson School of Engineering are harnessing those imperfections to make the material stronger while retaining its flexibility.

The investigators are designing metastable alloys that can overcome the well-known trade off between strength and ductility, revealing a strategy that can create alloys suited to a broad range of applications.

“Our work is showing how we can include intentional flaws in an alloy to make it stronger while retaining the ductility, or flexibility, of the material,” said Wei Xiong, assistant professor of mechanical engineering and materials science, whose Physical Metallurgy and Materials Design Laboratory led the study. “The techniques we are developing can be used to make materials fit for earthquake construction, naval ships, aerospace, nuclear energy, or even transportation for oil or hydrogen—all applications where a strong but flexible material is crucial.”

This study looks at two mechanisms for metastability engineering that can be used to create strong, ductile alloys: transformation-induced plasticity (TRIP) and twinning-induced plasticity (TWIP). TRIP and TWIP use changes in the microstructure that occur under pressure, which cause some defects in the material, to form purposeful defects that improve the strength.

“You can think of the strength and ductility of a material like plastic versus glass. Plastic is much more ductile and flexible: It is not as strong, but you can bend it with your hands,” explained Xiong. “Glass is stronger than plastic, but it’s also much less flexible and will break if you try to bend it. This is the trade off that we are trying to overcome with alloys—something that has both strength and ductility.”

To conduct their study, Xiong worked with lead author Xin Wang, graduate student in the Physical Metallurgy and Materials Design Laboratory, as well as researchers at the the Illinois Institute of Technology and Northwestern University.

The CALPHAD modeling supported by density functional theory calculations by the team provides fundamental knowledge that can be applied to developing metastable alloys with TRIP/TWIP for enhanced strength-ductility synergy. It also can be applied to concentrated alloys, like steel and nickel.

“We want to understand the unstable microstructure so we can predict the instability, and then we can use the defects to further increase strength and elongation,” said Wang. “The resulting material is then self-strengthening—deform it, and it actually gets stronger.”

The paper, “Design metastability in high-entropy alloys by tailoring unstable fault energies,” (DOI: 10.1126/sciadv.abo733) was published in the journal Science Advances.

Journal

Science Advances

DOI

10.1126/sciadv.abo733

Article Title

Design Metastability in High-Entropy Alloys by Tailoring Unstable Fault Energies

Article Publication Date

9-Sep-2022