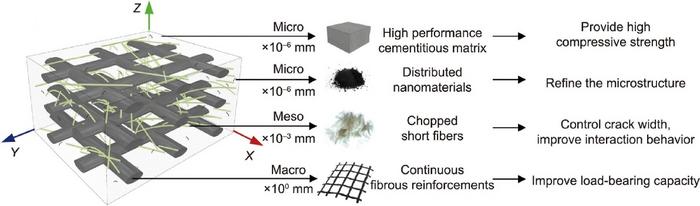

A groundbreaking research effort by Peizhao Zhou and Peng Feng from Tsinghua University has culminated in the development of a novel construction material known as flexible ultra-high performance reinforced cementitious composite (FHPRC). This innovative material is poised to redefine the landscape of the construction industry due to its impressive mechanical properties and versatility. The study published in the reputable journal Engineering propagates the idea that the integration of multiscale fibrous reinforcements can enhance the performance of cementitious matrices significantly.

The focus of the research was on the optimization of tensile behavior through the strategic selection of fiber types, sizes, and volume fractions. In an era where the durability and adaptability of building materials are crucial, FHPRC stands out by synergizing the remarkable strength and longevity of ultra-high performance concrete (UHPC) with the outstanding ductility and crack control of engineered cementitious composites (ECC). These enhancements allow FHPRC to attain not only a compressive strength of up to 160 MPa but also a tensile strength of 36 MPa. Its ultimate tensile strain exceeds 1%, and it demonstrates an ability to limit crack widths to less than 0.1 mm, allowing for substantial resilience and longevity in diverse construction applications.

The team led by Zhou and Feng validated the efficacy of FHPRC through rigorous experimental analysis. They designed and fabricated 30 plate specimens across ten distinct groups, which were subsequently subjected to four-point bending tests. These tests aimed to explore the flexural behavior of the composite in-depth, particularly examining how different types of strain-hardening cementitious composites (SHCC), various fiber-reinforced polymer (FRP) configurations, and the interplay of reinforcement types affect overall performance.

Notably, their findings revealed that the combination of carbon fiber reinforced polymer (CFRP) textiles with short steel fibers manifests remarkable enhancements in mechanical properties when compared to unreinforced UHPC. The results indicated that the load-carrying capacity of UHPC plates infused with FRP enhancements could improve significantly—by as much as 163.5%. Moreover, the ultimate deflection witnessed improvements of 331.7%, showcasing the composite’s impressive resilience under loading conditions.

Alongside physical experimentation, Zhou and Feng further developed advanced numerical models to deepen their understanding of the flexural characteristics of FHPRC. By employing an equivalent constitutive model based on the smeared crack approach, they successfully simplified the intricate numerical challenges associated with simulating matrix cracking. This model was used to replicate three independent bending experiments, effectively demonstrating its predictive prowess regarding the mechanical behavior of FHPRC. Strikingly, the newly proposed model exhibited a significant reduction in root mean square errors—93.1% for ultimate deflection and 90.0% for load-carrying capacity—when contrasted with traditional uncorrected models.

The implications of this research extend far beyond mere academic curiosity. The development of FHPRC represents a significant step forward in advanced construction materials, making it a prime candidate for applications in super-high-rise buildings, long-span spatial structures, and ultra-thin shell designs. Its unique combination of high strength, enhanced ductility, and reliable crack control means that it can address various structural demands, potentially leading to safer, more efficient construction practices.

Moreover, while the study primarily targeted fibrous reinforcements, the potential exists to explore the impact of nanomaterials on the mechanical properties of FHPRC. This offers fertile ground for future research initiatives aimed at optimizing composite materials further. It highlights the need for ongoing investigation into sustainable construction practices, as the demand for materials that can withstand the rigors of time and environmental stressors continues to grow.

As the global construction industry grapples with challenges such as resource sustainability, stiffness, strength, and environmental friendliness, FHPRC could represent a turning point. By merging superior characteristics from various material types, this new composite could lead to advancements in how we approach the design and construction of infrastructure. This could be especially crucial as urban populations surge and the guiding principle becomes not just building but constructing with foresight towards durability and sustainability.

In conclusion, the research spearheaded by Zhou and Feng marks a significant milestone in the journey toward innovative and sustainable construction materials. By redefining the fabric of composite materials through the introduction of FHPRC, they have laid the groundwork for substantial advancements in engineering solutions. The future is promising, with FHPRC offering numerous possibilities for revolutionizing how construction materials are perceived and employed across various sectors, ultimately benefiting industries and communities at large.

Subject of Research: Development of Flexible Ultra-High Performance Reinforced Cementitious Composite (FHPRC)

Article Title: Flexible Ultra-High Performance Reinforced Cementitious Composite Plates Based on Multiscale Fibrous Reinforcements

News Publication Date: 21-Feb-2025

Web References: Engineering Journal

References: DOI: 10.1016/j.eng.2025.02.005

Image Credits: Credit: Peizhao Zhou et al.

Keywords

Flexible ultra-high performance reinforced cementitious composite

Construction materials

Multiscale fibrous reinforcements

Engineering composites

Structural performance

Sustainable construction materials

Advanced materials science

Tags: crack control in construction compositesdurability of building materialsengineered cementitious compositesflexible ultra-high performance reinforced cementitious compositehigh-performance construction materialsinnovative construction technologiesmechanical properties of cementitious matricesmultiscale fibrous reinforcementsresilience in construction applicationstensile behavior optimizationTsinghua University research advancementsultra-high performance concrete advantages