In a groundbreaking advancement that promises to revolutionize the design and optimization of lithium-ion batteries, researchers Li, Zhao, Gwan, and their team have developed a high-fidelity hierarchical modeling framework combining electrochemical and mechanical properties across multiple scales. Their pioneering work, published in the esteemed journal Communications Engineering in 2025, introduces a novel cross-scale approach that intricately captures the complex interplay between electrochemical processes and mechanical deformations within lithium-ion cells. This interdisciplinary breakthrough is poised to significantly enhance battery performance, longevity, and safety, addressing critical challenges facing modern energy storage technologies.

At the heart of this innovative framework lies a hierarchical modeling strategy that integrates phenomena occurring at the atomic, particle, electrode, and cell levels into a unified simulation environment. Traditional battery models often simplify or disregard the coupled mechanical stresses generated during charge-discharge cycles, limiting predictive accuracy. However, the new approach meticulously bridges electrochemical reactions with the resulting mechanical strain and stresses accumulating over time. This linkage is vital to comprehensively understanding how lithium-ion intercalation causes volume changes that can degrade electrode integrity and ultimately impair battery function.

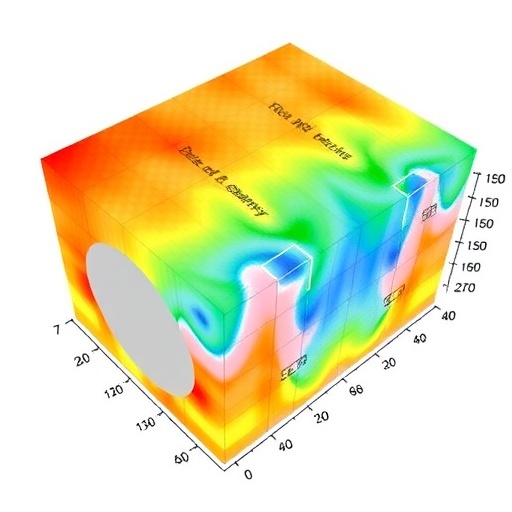

The researchers have harnessed a range of sophisticated numerical techniques to achieve this multiscale coupling. By incorporating finite element methods to resolve mechanical deformation dynamics and leveraging phase-field modeling for microstructural evolution, the framework captures both macroscopic and microscopic behaviors. Meanwhile, electrochemical kinetics and ion transport are modeled through high-resolution continuum approaches, ensuring a robust depiction of charge transfer and diffusion phenomena. This synergy enables simulations that reflect real-world battery operation with unprecedented detail and reliability.

One of the most striking aspects of this work is its capacity to predict mechanical failure modes such as crack initiation and propagation within electrode materials. Electrochemical processes inherently induce swelling and contraction, engendering stress fields that can exceed the mechanical limits of active particles and binders. By accounting for these coupled effects, the model can forecast degradation pathways far earlier than empirical methods, empowering engineers to tailor material properties and cell designs for enhanced durability. This predictive capability marks a critical step toward extending battery lifecycle and safety margins.

Furthermore, the hierarchical framework offers valuable insights into the impact of microstructural heterogeneity on overall battery behavior. Real electrodes display complex particle size distributions and morphological anisotropies, factors known to significantly influence mechanical stress landscapes and electrochemical activity. Simulations demonstrate how these microstructural features interact with ion transport and reaction rates to produce heterogeneous degradation patterns. Such understanding facilitates the engineering of microstructures optimized for uniform reaction distributions and minimized mechanical damage.

The cross-scale nature of the framework also proves essential for optimizing charging protocols that mitigate mechanical degradation. Battery usage patterns, particularly fast charging, exacerbate mechanical stresses by inducing steep concentration gradients and non-uniform expansion. The model allows exploration of various cycling scenarios, quantifying how different rates and depth-of-discharge profiles influence stress evolution and damage accumulation. This capability opens pathways to intelligent charging algorithms that maximize battery life without sacrificing performance.

Crucially, the framework’s modular design ensures adaptability to diverse battery chemistries beyond conventional lithium-ion systems. As next-generation materials such as silicon anodes, solid-state electrolytes, and lithium-sulfur cathodes gain prominence, their distinct electrochemical-mechanical interactions can be systematically incorporated. This flexibility positions the modeling approach as a versatile tool capable of accelerating innovation across a broad spectrum of energy storage technologies.

Experimental validation further corroborates the accuracy and predictive power of the hierarchical model. The authors performed extensive comparisons with in situ microscopy observations and mechanical testing data, revealing excellent agreement between simulated stress distributions, crack evolution patterns, and observed physical changes. This validation underscores the model’s utility as a reliable virtual testing platform, reducing reliance on costly and time-consuming experimental campaigns while providing deep mechanistic insight.

The broader implications of this work extend to electric vehicle and consumer electronics industries, where battery reliability and longevity remain paramount concerns. Enhanced understanding of degradation mechanics at multiple scales enables manufacturers to design safer, more robust batteries that meet the demanding cycling conditions of real-world applications. Additionally, improved battery management systems informed by these insights can ensure optimal operation, safeguarding users from risks such as thermal runaway and capacity loss.

The fundamental scientific contributions of the research also pave the way for deeper exploration into coupled chemo-mechanical phenomena in solid-state materials. Lithium-ion batteries represent one of the most complex engineered systems involving dynamic interactions between ionic, electronic, and mechanical transport. The hierarchical modeling framework thus serves as a blueprint for studying similar challenges in varied domains, including fuel cells, supercapacitors, and beyond.

By strategically uniting multidisciplinary expertise in electrochemistry, materials science, and computational mechanics, the team has set a new standard for predictive modeling in energy storage science. Their work exemplifies how synergistic integration of experimental data with advanced numerical methods can unravel intricate physical phenomena, driving systematic improvements in technology. As the global push toward renewable energy and electrification intensifies, such sophisticated tools will be instrumental in realizing the next generation of high-performance batteries.

In summary, Li and colleagues’ high-fidelity hierarchical modeling framework marks a seminal advancement in lithium-ion battery research, enabling comprehensive cross-scale analysis of electrochemical and mechanical coupling. This innovative approach unlocks vital insights into degradation mechanisms, informs optimized material and cell designs, and guides improved operational strategies. With ever-growing demand for safe, durable, and efficient energy storage, the paradigm established by this study promises to accelerate the transition toward sustainable electrification and usher in new horizons for battery science.

Subject of Research:

High-fidelity hierarchical modeling of lithium-ion batteries considering coupled electrochemical and mechanical phenomena across multiple length scales.

Article Title:

High-fidelity hierarchical modeling of lithium-ion batteries: a cross-scale electrochemical-mechanical framework.

Article References:

Li, X., Zhao, S., Gwan, C. et al. High-fidelity hierarchical modeling of lithium-ion batteries: a cross-scale electrochemical-mechanical framework. Commun Eng (2025). https://doi.org/10.1038/s44172-025-00567-3

Image Credits: AI Generated

Tags: cross-scale approach in battery designelectrochemical and mechanical properties integrationenhancing battery longevity and safetyfinite element methods in battery researchhierarchical modeling framework for batterieshigh-fidelity modeling of lithium-ion batteriesinterdisciplinary research in energy storage technologieslithium-ion battery performance optimizationlithium-ion intercalation and volume changesmechanical deformation in battery cellsmultiscale simulation techniquespredictive accuracy in battery modeling