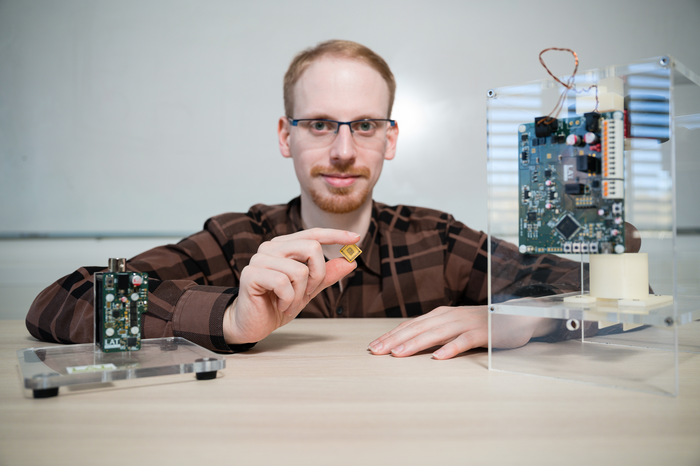

New technology is making it possible to control valves and locking devices without the need for any additional sensors. A metal piston, a tiny chip and small pulses of current – that’s all that the drive systems specialists led by Professor Matthias Nienhaus of Saarland University need for their sustainable and cost-effective technology. The continuously adjustable piston can move back and forth slowly or quickly as required, can hold any position and can return softly to its stop position if desired. The patented actuation technology requires very little energy and can be integrated into systems via a specially developed chip. The team will be showcasing their innovative technology at the Hannover Messe from April 17 to 21 (Hall 002, stand B34).

Credit: Credit: Oliver Dietze

New technology is making it possible to control valves and locking devices without the need for any additional sensors. A metal piston, a tiny chip and small pulses of current – that’s all that the drive systems specialists led by Professor Matthias Nienhaus of Saarland University need for their sustainable and cost-effective technology. The continuously adjustable piston can move back and forth slowly or quickly as required, can hold any position and can return softly to its stop position if desired. The patented actuation technology requires very little energy and can be integrated into systems via a specially developed chip. The team will be showcasing their innovative technology at the Hannover Messe from April 17 to 21 (Hall 002, stand B34).

They close, open, dose and mix: solenoid valves are used in millions of applications, from automatic locking systems for doors to dishwashers, heating and compressed air systems or in the food industry. Although they are fast and reliable, they are also usually quite inflexible. Standard solenoids are able to ‘open’ and – often rather abruptly – ‘close’. However, if they need to open slowly or especially quickly, hold a certain position or land softly and silently at the stop position, things tend to get expensive. Additional sensors then have to be integrated into the system, requiring the installation of technical components and cables, and invariably complicating matters. During operation, these more complex designs then consume more power. If a locking device needs to hold a position such as ‘open’ or ‘closed’ – as is the case with some fire doors – this can mean continuous power consumption, which can really start to become costly.

The sustainable solutions developed by Professor Matthias Nienhaus’ research group at Saarland University do not require any additional sensors. Especially when it comes to systems that continuously need power to hold a position such as ‘open’ or ‘closed’, the new technology can minimize the energy required. All that’s needed is a magnetically conductive metal pin in a coil of wound copper wire and a small microchip within the drive electronics. ‘We don’t need anything else. We only use the original components of a simple solenoid,’ explains Matthias Nienhaus. This means their technology can be used even in harsh environments. ‘This is where systems that rely on sensors often reach their limits, such as when oil or brake fluids are involved,’ says drive specialist Nienhaus.

By simply evaluating the current that flows through the coil in order to move the valve piston, the Saarbrücken researchers can detect the position of the piston and control it quickly and accurately. The electric current provides the engineers with all the information they need. “We monitor the inductance. We analyse the flow of the current in the winding over time. What that means is that we measure voltage and current, look at fluctuations over a certain period of time, analyse them and use them to observe the magnetic state,” explains doctoral student Niklas König, who is researching this process as part of his doctoral thesis with Matthias Nienhaus.

The magnetic state and thus the current fluctuations change depending on where the piston is at any given time. ‘This enables us to know precisely where the piston is. Using this information, we can control the position of the pin efficiently and precisely,’ explains Niklas König. This means that the engineers can move the piston slowly or very quickly as required – or they can move it quickly but then ensure it moves softly just before it reaches the designated stop position. In order to achieve this, the researchers have modelled movement sequences and can use intelligent algorithms to individually program the different piston positions. The system can also be used to monitor whether a specific position of the pin is maintained, for example whether the valve is actually closed, thus enabling an integrated safety check to be performed. All of these innovative capabilities expand the potential areas of application for the technology.

This elegant solution is also cost-effective. ‘Our technology comes as a complete package that includes the associated microelectronics,’ explains Matthias Nienhaus. The chip that they have developed contains all the patented technology and handles the key parts of the control system. It is comparatively easy to install and the amount of power required is relatively low. ‘In fact, it can even save electricity. With an unregulated system, holding a specific position requires a continuous supply of energy and can quickly drain the batteries. With our invention, in contrast, evaluating small current pulses is all that is needed to ensure the correct position and only minimal energy is required to maintain it,’ he explains.

The invention is based on sophisticated technology. The signals that the researchers receive from the coil are not very informative in themselves; on the contrary, the signals are very noisy. ‘We smooth these signals using a specially developed, patented method,’ Nienhaus explains. The engineers filter out the relevant measurement signals. ‘It is rather like continuously calculating the average speed when driving a car, where you are sometimes driving quickly and sometimes slowly,’ Nienhaus elaborates. The results allow the researchers to precisely determine where the pin is located in the winding. ‘The result is an almost noiseless measurement signal. We can use this to position the pin precisely, even if it slightly outside the coil,’ he explains.

At the Hannover Messe, the engineers will showcase their technology and demonstrate its precision and dynamics by controlling a floating steel ball so that it floats up and down on command – using only current control signals and without any additional sensors.

The research was funded by the German Ministry for Economic Affairs and Climate Action (BMWK). The microchip was developed in collaboration with the Fraunhofer Institute for Microelectronic Circuits and Systems (IMS) in Duisburg.