“Future Hub” and “Energy Solutions”: KIT showcasing selected highlights of technology development at two virtual booths from April 12 to 16

Credit: (Photo: wbk, KIT)

A plant-inspired anti-reflective film, a flexible production system for individualized products, a digital assembly assistant, the world’s smallest transistor, and climate-neutral synthetic fuels. Karlsruhe Institute of Technology (KIT) will present these and other research and innovation topics at the Hannover Messe 2021. At the digital event from April 12 to 16, the KIT will showcase selected highlights at the virtual booths “Future Hub” and “Energy Solutions”. An overview will be provided by the two live streams on April 13, 2021, from 11:00 a.m. to 11:25 a.m. on the “Future Hub” and on April 14, from 10:30 a.m. to 10:55 a.m. on “Energy Solutions”.

Please refer to the digital press portfolio at https:/

“Whether in megatrends such as digitization or in the switch to climate-friendly production – the world of industry is in a state of upheaval. At this year’s Hannover Messe, we will present developments with which we can actively shape this change,” says President of KIT Professor Holger Hanselka. “At two virtual booths, we will present technologies, methods, and projects which all make one thing clear: A resilient and innovative industry thrives on the pioneering work of the researchers – and this is where we make a decisive contribution.”

To kick off the Hannover Messe 2021, Professor Holger Hanselka will join Federal Research Minister Anja Karliczek and other participants from politics and industry on the podium at the Night of Innovations on Monday, April 12, from 5:00 p.m. to 6:00 p.m. on the topic of “Kreislaufwirtschaft – Von der Idee zur Umsetzung” (Circular Economy – From Idea to Implementation). https:/

The KIT in the “Future Hub”

Live stream with a brief presentation of topics on April 13, 2021 from 11:00 a.m. to 11:25 a.m. at: https:/

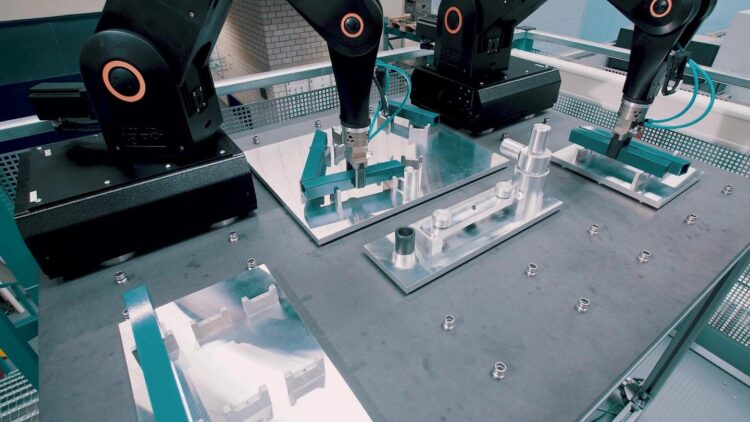

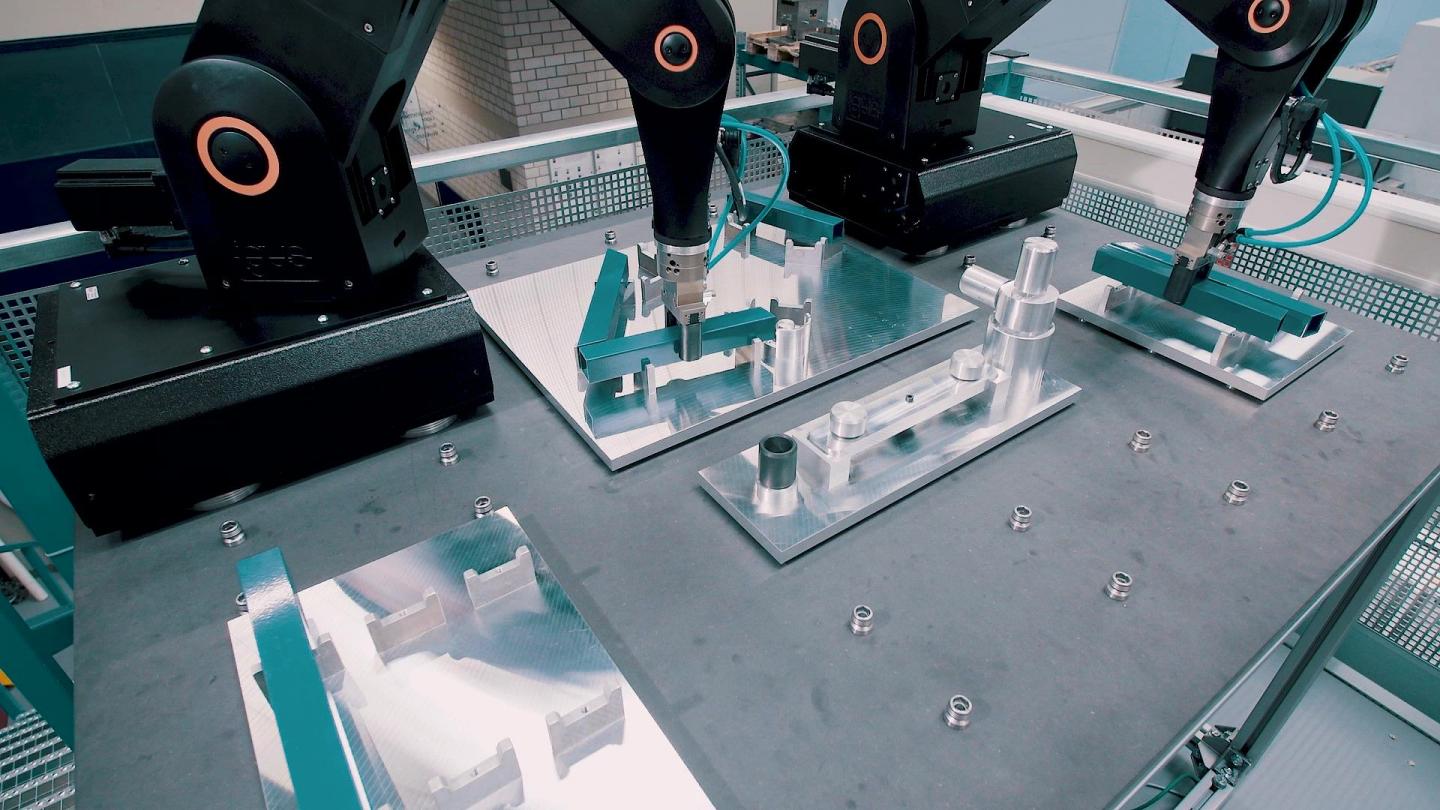

Industry 4.0: A Flexible Production System for a Wide Range of Product Variants

From car accessories to sports shoes – producing individually designed high-quality industrial and consumer goods in smaller quantities economically and competitively requires flexible manufacturing processes. Value stream kinematics makes it possible to combine the high productivity and precision of special machines with the flexibility and adaptability of industrial robots. This innovative production system focuses on mapping entire production flows using uniform standard kinematics that can be freely positioned in space and coupled as required for greater stiffness and accuracy. This makes them suitable for a wide range of process tasks, from handling to e.g. machining and assembly through to quality assurance.

Professor Jürgen Fleischer, Head of KIT’s Institute of Production Science (wbk) will present this topic during on the digital Press Highlight Tour on April 8, 11:00 a.m. to 1 p.m.

(http://www.

Video “Flexible Production System Enables Variety of Variants”: https:/

Biomimetic Surfaces: Nano- and Microstructured Surfaces Inspired by Nature

Nature often has the best ideas: In the course of the evolution, many plants and animals have developed nano- and microstructured surfaces with fascinating properties. Biomimetics imitates these solutions from nature and makes them technically usable: Modeled on the white beetle Cyphochilus insulanus, a nanostructured polymer film forms a brilliant white coating for various products. An aquatic plant-inspired nanofur with specially arranged structures on a plastic film effectively separates oil and water and enables oil spills on water bodies to be removed quickly and in an environmentally friendly manner.

Video ” Biomimetic Surfaces: Nano- and Microstructured Surfaces Inspired by Nature”: https:/

Video “Biomimetic Surfaces” (Interview with Professor Hendrik Hölscher): https:/

Anti-reflective Films: Anti-reflective Surfaces Modeled on Plants

Another innovation inspired by nature: The KIT spin-off Phytonics presents an anti-reflective film that creates the velvety-matt color impression of petals by eliminating reflections on surfaces. On photographs, display panels, furniture, packaging, facades, and solar modules, the film can almost completely suppress reflection for all wavelengths and angles of incidence of light. In the case of solar modules, this leads to an increase in yield of up to ten percent. Manufactured in a roll-to-roll process, the film is cost-effective, mechanically flexible, and resistant to environmental influences.

Video “A Plant-inspired Film Eliminates Surface Reflections”: https:/

Artificial Intelligence: Camera-based Spindle Control

Machine tools require regular maintenance, and defective components must be replaced in good time. An intelligent camera system for quantifying surface defects on ball screw drives that are used, for example, in lathes for precision guidance in the manufacture of cylindrical components, allows image-based, direct monitoring of the spindle surface. It consists of a camera system with lighting mounted on the ball screw nut, combined with a machine learning model trained on image data.

Video “Camera-based Spindle Control: A Learning Model for Wear Quantification”: https:/

Digital Assembly Assistants: Automatic AI-supported Object Recognition

The startup Kimoknow, which emerged from the KIT, has developed a technology that makes machine vision more accessible to everyone, especially in places where it has not been efficient so far. For example, the digital assembly assistant KIMO enables more efficient cooperation between humans and machines. Using AR glasses and object recognition, it supports specialists in the assembly of complex devices, making the process more efficient and increasing the quality of the products. To train the system to recognize objects in a time- and cost-saving way, Kimoknow uses image data from computer-aided design (CAD) processes and product lifecycle management (PLM). The effort is thus significantly reduced and enables far more diverse applications than before.

Video “Digital Assembly Assistant: Automatic AI-supported Object Recognition”: https:/

The KIT in “Energy Solutions”

Live stream with a brief presentation of topics on April 14, 2021 from 10:30 a.m. to 10:55 a.m. at: https:/

reFuels: Fuels for CO2-neutral Mobility

The reFuels research initiative aims to enable all vehicles to be fueled with renewable fuels in order to quickly provide a complementary solution for CO2-neutral mobility. It deals with the composition, production, and use of regenerative fuels and uses innovative infrastructures for this purpose: For the bioliq® process, with which high-quality fuels can be produced from biogenic raw and residual materials, for example straw, a plant supplying gasoline already exists at KIT. The Energy Lab 2.0 at KIT, which is unique worldwide, combines state-of-the-art technologies for the generation and use of electrical, thermal, and chemical energy such as gas turbines, power-to-methane, and water electrolysis; in addition, it produces various fuel components.

Video “Regenerative Fuels as Building Blocks of CO2-neutral Mobility”: https:/

Energy Efficiency: World’s Smallest Transistor with Enormous Potential

Whether in data processing centers, PCs, smartphones, or embedded systems for various applications from households to medical technologies – transistors are the central elements of digital data processing. The world’s smallest transistor switches current through the controlled reversible movement of a single atom. This quantum-electronic element enables switching energies that are by a factor of 10,000 lower than those of conventional silicon technologies. The single-atom transistor already works at room temperature. It operates in a gel electrolyte that combines the advantages of a solid with the electrochemical properties of a liquid. With this tiny transistor as a functional element, the energy efficiency of digital data processing could be increased enormously.

Resilience: Digital Power Supplies for Longer Service Lives and Reliability

From smartphone chargers to charging stations for electric cars: Switching power supplies are ubiquitous in the power supply of electrical devices. Thanks to their precise and flexible control, the newly developed digital power supplies are particularly well suited for industrial applications with high dynamic requirements. A new modulation method for digital and highly dynamic control of power supplies allows the use of film capacitors with only slightly increased installation space. The long service life of the film capacitors reduces the failure rate of the switching power supplies and thus increases the service life of the end devices. The power supplies can be integrated into the Internet of Things via an online monitor for remote maintenance or remote diagnostics. Digital power supplies thus will advance Industry 4.0.

greenventory: Inventorying and Optimization of Energy Systems

With the software developed by the startup greenventory, energy supply and climate protection concepts, for example for production sites, distribution networks, or living quarters, can be created much faster and with higher quality than before. The software provides companies and cities with the spatially and temporally highly resolved database required for forward-looking planning. The latter contains all energy-relevant building parameters and includes the grid infrastructure as well as potential for wind power and photovoltaic systems. In a holistic system analysis, the software considers heat, electricity, and mobility. With greenventory, the latest energy management findings reach the user directly.

Video “greenventory: Software for Inventorying Energy Systems”: https:/

The KIT at Other Virtual Booths

Process for Flexible Battery Cell Stack Formation Showcased at the Siemens Virtual Booth

At the virtual booth of Siemens AG, KIT will present a new solution for battery production: The Coil2Stack process allows battery cell stacks to be produced efficiently, precisely, and flexibly. A newly designed production system with movable axes conveys, cuts, and handles electrode and separator sheets of variable widths and lengths and stacks them precisely and without damage. The process speeds up the production process and makes the production line independent of formats. Coil2Stack also allows cascaded cell stacks, which considerably facilitates integration into products such as notebooks.

Transformation Hub Electric Mobility Showcased at the Baden-Württemberg Virtual Booth

Ready for electric mobility: KIT’s wbk Institute of Production Science presents the three research projects SmartBatteryMaker, Fit4E, and Training Factory Stator Manufacture of the Transformation Hub Electric Mobility at the Baden-Württemberg virtual booth. These combine flexible solution approaches and demand-oriented training models to enable, in particular, mechanical and plant engineering companies to successfully shape the transformation to battery, fuel cell, and e-motor production.

The KIT in the Conference Program: Lecture on the Industrial Transformation

On April 14, 2021, from 9:30 a.m. to 10:00 a.m., Vice-President for Innovation and International Affairs at the KIT Professor Thomas Hirth will give the lecture “Industrielle Transformation – Klimaschutz und Ressourceneffizienz” (Industrial Transformation – Climate Protection and Resource Efficiency) on the Smart Industries Channel.

Please refer to the digital press portfolio at https:/

Read more:

Hannover Messe 2021: https:/

The KIT in the “Future Hub”: https:/

The KIT in “Energy Solutions”: https:/

Information on Accreditation: https:/

Contact for This Press Release:

Margarete Lehné, Deputy Press Officer, phone: +49 721 608-41157, Email: [email protected]

Being “The Research University in the Helmholtz-Association,” KIT creates and imparts knowledge for the society and the environment. It is the objective to make significant contributions to the global challenges in the fields of energy, mobility and information. For this, about 9,600 employees cooperate in a broad range of disciplines in natural sciences, engineering sciences, economics, and the humanities and social sciences. KIT prepares its 23,300 students for responsible tasks in society, industry, and science by offering research-based study programs. Innovation efforts at KIT build a bridge between important scientific findings and their application for the benefit of society, economic prosperity, and the preservation of our natural basis of life. KIT is one of the German universities of excellence.

This press release is available on the Internet at https:/

###

Media Contact

Monika Landgraf

[email protected]

Original Source

https:/