Researchers find that a promising photoelectrode material for producing hydrogen using sunlight can be made even better by increasing its surface roughness

Credit: NITech

In the present context of concerning CO2 levels and sustainability issues, the search for efficient and clean alternatives for producing energy continues. Among the most attractive ecofriendly fuels known, hydrogen stands out and there is much potential for its use. But researchers are yet to come up with a cost-efficient and scalable method to produce large amounts of hydrogen, and a hydrogen economy is still not on the cards. For instance, hydrogen can be produced from fossil fuels, but the process generates CO2 and is, therefore, not sustainable. An environment-friendly approach to producing hydrogen is water splitting: breaking up water molecules (H2O) to obtain pure hydrogen (H2). The energy that this process requires can be harvested directly from solar radiation using photoelectrochemical cells. These cells are composed of two electrodes and a material called the electrolyte; the characteristics of all three are tailored to trigger and favor the necessary water splitting reactions.

One important characteristic that determines the efficiency of the water splitting reaction is the “band gap” of the photoelectrode material. The band gap is broadly a measure of the energy that the electrodes must receive so that charge can transfer through them and the reaction can occur. Photoelectrode materials with moderate band gaps are desirable because less energy would have to be captured from solar radiation to cause charge circulation. In light of this, silicon carbide (SiC) electrodes have been explored as a promising option. Now, scientists from Nagoya Institute of Technology, Japan, have contributed to a better understanding of these materials. “SiC is one of the most promising photoelectrode materials owing to its durability. Among its various types, 3C-SiC can absorb part of visible light due to its moderate band gap and is also capable of hydrogen generation,” explains Dr Kato the lead scientist of this study published in Applied Physics Express. Nonetheless, the observed performance of existing 3C-SiC photoelectrodes is still lower than that predicted through theoretical calculations.

To bridge this gap and improve performance, the scientists applied a previously reported approach: the efficiency of photoelectrodes can be improved by giving them a textured structure. A rugged surface allows the incident light to pass through the material multiple times, increasing the amount of sunlight absorbed.

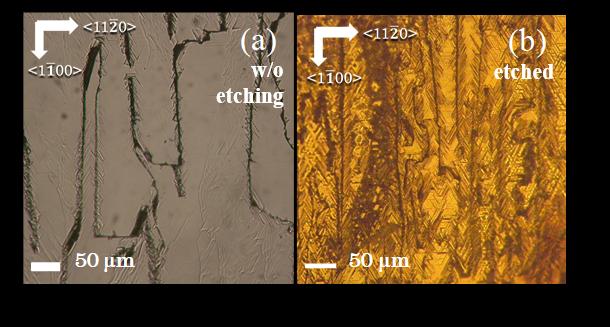

In this study, to make the 3C-SiC photoelectrode surfaces textured, Dr Kato and his colleague employed a technique called “electrochemical etching.” They then compared the optical and electrical properties and the performances of several photoelectrodes etched under various conditions. They also observed all surfaces through advanced microscopy techniques.

They saw that the etching had occurred preferentially on the existing faults and dislocations on the material’s surface. Its surface roughness was greatly increased (as desired), without the formation of “point defects”–anomalies in the base structure of the electrode.

Its performance–measured through its photon-to-current conversion efficiency under an applied voltage (also known as “ABPE” or “applied bias photon-to-current conversion efficiency”)–showed improvement. Under optimal conditions of etching and platinum cocatalyst deposition, the performance was found to be 2%. “This ABPE value is the highest among the reported efficiencies for SiC photoelectrodes so far. Thus, we believe our 3C-SiC photoelectrode with a surface texture formed through electrochemical etching is promising for solar-to-hydrogen energy conversion applications,” concludes Dr Kato.

The scientists say that their ultimate goal is to someday produce SiC photocathodes with solar-to-hydrogen efficiencies comparable to those of other energy conversion technologies. Realizing this vision could be a key step towards a more environment-friendly hydrogen economy.

###

Media Contact

Azusa Yabugami

[email protected]

Related Journal Article

http://dx.