Researchers led by Prof. HUANG Qing from the Ningbo Institute of Materials Technology and Engineering (NIMTE) of the Chinese Academy of Sciences, in collaboration with researchers from the Zhejiang Institute of Tianjin University, and Linköping University, Sweden, has proposed a general A-site alloying strategy for the preparation of noble metal-occupied MAX phases.

Credit: NIMTE

Researchers led by Prof. HUANG Qing from the Ningbo Institute of Materials Technology and Engineering (NIMTE) of the Chinese Academy of Sciences, in collaboration with researchers from the Zhejiang Institute of Tianjin University, and Linköping University, Sweden, has proposed a general A-site alloying strategy for the preparation of noble metal-occupied MAX phases.

This work was published in Matter.

MAX phases are a family of ternary layered transition metal carbides that have attracted great attention as high-temperature structural materials. Researchers have gradually expanded the types of atoms in A-sites from traditional main group elements to include subgroup elements with an outer layer three-dimensional (3D) electronic structure. However, research on MAX phases with A-site elements having 4d/5d-orbital electronic structures has been limited.

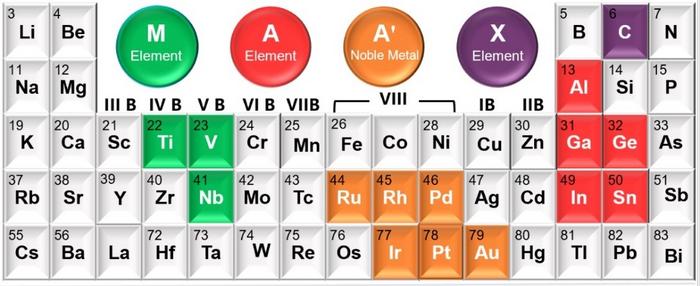

Prof. HUANG and colleagues delved into this obscure field and proposed a general A-site alloying strategy. This strategy enables the preparation of more than 100 MAX phases with noble metal-occupied elements in the A-site of the crystals, due to the diversity of chemical composition and crystal structure of MAX phases.

Specifically, one or more of the six noble metals, i.e., ruthenium, rhodium, palladium, iridium, platinum, and gold, occupy the A atomic layers, with aluminium, gallium, indium, germanium, tin, and other solid solution A-site elements being randomly selected. Titanium, vanadium, and niobium are used as the M-site elements.

By choosing the raw carbon powders, noble metal-occupied MAX phases with different morphologies were synthesized.

Compared with commercial Pt/C, the Pt-occupied MAX phase produced in this study exhibited superior catalytic performance for the alkaline hydrogen evolution reaction, including lower overpotential, lower Tafel slope, higher mass activity, and better cyclic stability.

The noble metal-occupied MAX phases produced via general A-site alloying show broad application prospects in electrocatalysis and beyond.

This work was supported by the “Pioneer” and “Leading Goose” R&D Program of Zhejiang, the Zhejiang Province Special Support Program for High-level Talent, and the National Natural Science Foundation of China, etc.

Journal

Matter

DOI

10.1016/j.matt.2023.12.006

Method of Research

Experimental study

Subject of Research

Not applicable

Article Title

A-site alloying-guided universal design of noble metal-based MAX phases

Article Publication Date

10-Jan-2024