Recent advancements in the field of adhesive bonding technology have paved the way for innovative applications across various industries, ranging from automotive engineering to aerospace and construction. With this evolution, researchers are increasingly focused on analyzing the mechanical performance of adhesive joints, particularly regarding their capacity to withstand fractures. A groundbreaking study conducted by Fatolahi, Mohsenikia, and Khoramishad explores an energy-based approach to fracture characterization of adhesive joints using a short-beam bend test method. This study adds significant insights into the durability and reliability of adhesive bonds, which are crucial for engineering applications where safety and performance are paramount.

In adhesive bonding, the interface between the adhesive and the substrates is critical. The nature of this interface often dictates the overall performance of the bonded assembly. The researchers note that traditional methods of fracture characterization often fail to provide a complete picture of the energy mechanics involved during failure. To fill this gap, the authors present a novel energy-based fracture characterization approach which can facilitate a deeper understanding of adhesive joint performance under mechanical stress.

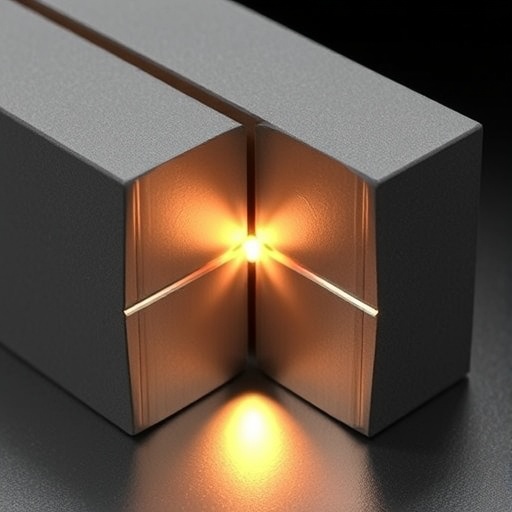

The short-beam bend test, a pivotal element of this research, serves as a primary evaluation method. This test is relevant because it inherently emphasizes the fracture toughness of the adhesive layer by limiting the bending stresses experienced by the joints. The results gleaned from this test can yield valuable data on the adhesive’s capacity to transfer load and resist failure during application. Understanding these parameters is crucial in industries where structural integrity is vital.

The methodology employed in the study illustrates the intricate relationship between adhesive thickness and the resultant mechanical performance. By varying the adhesive thickness in their experiments, the researchers were able to decipher how this variable impacts the energy release rate during fracturing. Their findings suggest that there exists an optimal adhesive thickness that maximizes energy absorption before failure occurs. This is an essential consideration for engineers and designers who must select or formulate adhesives for specific applications, ensuring that the adhesive meets desired performance criteria under operational conditions.

Moreover, the researchers employed advanced analytical techniques and simulations to complement empirical findings. These approaches allowed them to model the fracture mechanics of adhesive joints under different loading conditions accurately. By utilizing finite element analysis alongside experimental data, they explored the stress distribution within the adhesive layer and the substrates, providing a comprehensive perspective on failure mechanisms.

The practical implications of this research are profound, particularly for industries that rely on adhesion for structural applications. By establishing a better understanding of adhesive joint performance, manufacturers can improve product reliability, minimize failure rates, and enhance safety standards. Consider, for example, the automotive industry, where adhesive bonding plays a crucial role in vehicle manufacturing. The findings from this study can inform the development of stronger, more effective adhesive joints that withstand the rigors of daily use and environmental conditions.

One intriguing aspect of the study is its potential to influence future adhesive formulations. With insights into how various variables impact joint performance, chemists and material scientists may be inspired to create new adhesive materials tailored for specific mechanical properties, ultimately leading to more effective bonding solutions. This could also mean adhesives that are not only stronger but also more versatile, applicable in a wider variety of conditions and materials.

Furthermore, the research underscores the importance of standardized testing protocols for adhesive joints. As the use of adhesives becomes more widespread, the need for uniform testing standards becomes apparent. The authors advocate for the implementation of testing methodologies like the short-beam bend test across various sectors to ensure consistent evaluations of adhesive performance. Standardization can reduce discrepancies in data interpretation and open avenues for comparative studies, facilitating advancements in adhesive bonding technologies.

Sustainability and environmental considerations are also essential aspects of modern engineering solutions. As researchers address performance, they must simultaneously consider the environmental impact of their materials. The study’s findings regarding adhesive joint performance may inspire a shift toward more sustainable adhesive solutions that perform well while minimizing ecological footprints. Innovations in this area could contribute significantly to the development of eco-friendly bonding agents that meet industrial requirements without compromising environmental integrity.

As the research progresses, further studies will be necessary to validate and expand upon the findings presented. Future work might encompass a broader range of adhesive types, including thermosetting, thermoplastic, and bio-based adhesives. By conducting comprehensive analyses on the diverse classes of adhesives, researchers can achieve a holistic understanding of adhesive bond dynamics and their applicability across different environments and materials.

The authors also emphasize the need for ongoing collaboration between academia and industry. Engaging stakeholders from both realms can lead to practical applications of research findings, rapidly transitioning theories into real-world products and practices. Such partnerships can spur innovation and accelerate the development of new technologies that drive the adhesive bonding field forward.

In conclusion, the study by Fatolahi, Mohsenikia, and Khoramishad introduces a valuable approach to understanding adhesive joint performance through energy-based fracture characterization tailored via a short-beam bend test. The insights derived from their work not only deepen the understanding of adhesive mechanics but also bear significant implications for various industries that rely on adhesive technologies. As the demand for innovative adhesive solutions continues to rise, research like this will play a critical role in shaping the future of material bonding and engineering design.

Subject of Research: Energy-based fracture characterization of adhesive joints.

Article Title: Energy-based fracture characterization of adhesive joints using adhesively bonded short-beam bend test.

Article References:

Fatolahi, A.R., Mohsenikia, R. & Khoramishad, H. Energy-based fracture characterization of adhesive joints using adhesively bonded short-beam bend test.

Sci Rep 15, 37969 (2025). https://doi.org/10.1038/s41598-025-21948-w

Image Credits: AI Generated

DOI: 10.1038/s41598-025-21948-w

Keywords: Adhesive bonding, fracture mechanics, short-beam bend test, energy characterization, material performance, structural integrity, automotive engineering, sustainable adhesives.

Tags: adhesive bonding technologyadhesive joint durabilityautomotive and aerospace applicationsbonding interface performanceenergy-based fracture analysisengineering safety and performancefracture characterization of adhesive jointsfracture toughness assessmentinnovative applications in constructionmechanical performance of adhesive jointsmechanical stress evaluationshort-beam bend test method