Credit: Source: Islam K et al. Autofluorescence excitation-emission matrices as a quantitative tool for the assessment of meat quality. J. Biophotonics. 2019;e201900237. © 2019 Wiley-VCH Verlag GmbH & Co. KGaA. Reproduced…

Scientists of Sechenov University jointly with their colleagues from Australia proposed a new, quicker and cheaper way to assess meat quality. It is based on exposing a small sample to UV light and measuring the spectrum of emission. The method proved to be precise in the classification of meat into standard quality categories. The description of the method and the results of the work were published in Journal of Biophotonics.

Conventionally, to evaluate the quality of beef, specialists pay attention to its colour, pattern of the fibers (marbling), carcass weight etc. But such measurement is time-consuming and relies on a subjective opinion of the experts to a significant extent. Fluorescence spectroscopy can become an alternative: it allows to detect and measure the concentration of various compounds that can emit light of a specific frequency range. These substances include many organic molecules which can be found in meat.

Earlier studies described the spectrum of fluorescence of some meat ingredients (various cell types of muscle, adipose (fat), connective tissue); several scientific groups tried to use these data to assess particular characteristics of the product, e.g. the percentage of connective tissue or fatty acids. The authors of the paper in Journal of Biophotonics linked the spectrum of the fluorescence of meat with its quality defined by 3 categories: MSA3, MSA4 or MSA5. The results were additionally validated by histological (cell and tissue) analysis of the samples and measuring the concentrations of water and fat in them.

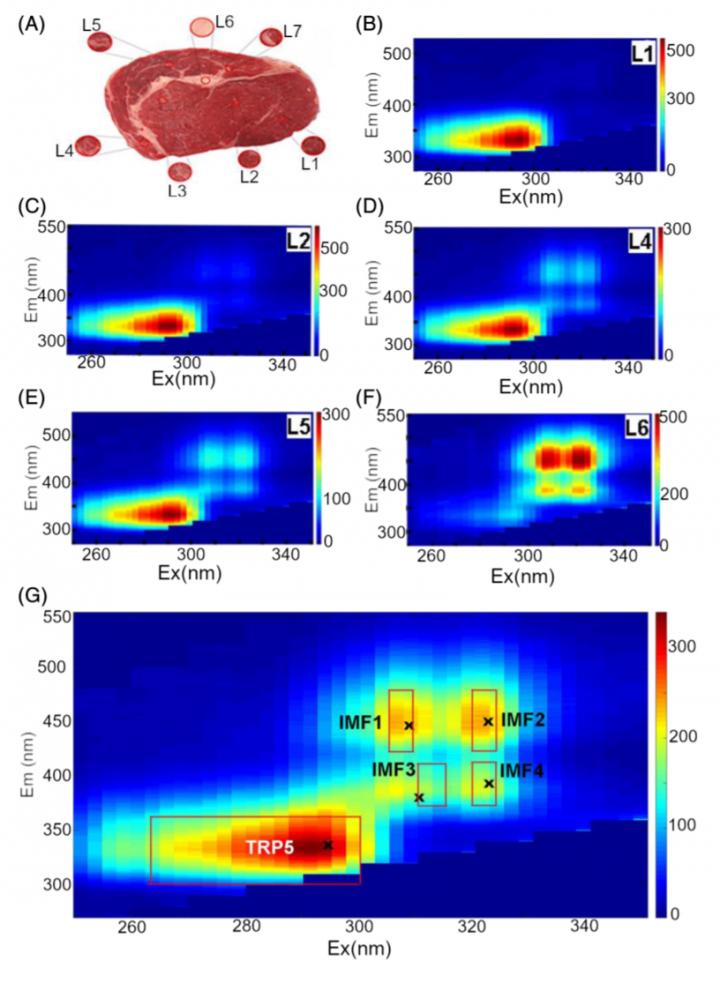

In their work scientists used five pieces of meat for each of three classes: MSA5 marks slices of the highest quality and MSA3 – of the lowest among the qualified meat types. Six samples, each of about 8 mm in diameter, were cut from different sites of the meat steaks, where the relative content of fat and muscle tissues varied. Researchers exposed the samples to the light with the wavelength of 250-350 nm (near and middle ultraviolet) and measured the spectrum of the fluorescence in a range of 285-635 nm (from middle ultraviolet to the border between visible light and infrared). The intensity of the emission was set on the matrix ‘frequency of excitation – frequency of emission’.

The results showed that the spectra of fluorescence of the samples with various ratios of muscle and adipose tissues are discernible. On the matrices of the samples with adipose tissue one can distinguish spots that match the spectrum of fluorescence of fat-soluble vitamins (A, D, K1, K2, K3), vitamin B and its components, while the spectrum of the samples with muscle tissue coincides with the spectrum of amino acid tryptophan it contains. The authors selected features that enabled them to define the category of any piece of meat. For example, the highest quality meat (MSA5) has the most intensive fluorescence and can be distinguished from the lower quality samples by the difference in brightness of various ranges. The data received also agree with the assumption that the presence of connective and adipose tissue makes meat more tender, and fat is responsible for its marbling.

‘This work shows the new opportunities to evaluate the quality of meat objectively by LED illumination and registration of the tissue optical response. It’s interesting to note that this technology, having being originally developed for the meat industry, can be further translated into medicine and biomedical research. The principle on which this study was based, i.e. the detection of specific autofluorescence of various tissue components, allows evaluation of the structure and functional state of tissues without taking tissue fragments for biochemical of histological analysis. Therefore, our study can be considered as a possible step towards non-invasive and pain free diagnostics in medicine as well’, said Dr Anna Guller, coauthor of the paper, senior research fellow of Sechenov University.

###

Media Contact

Nataliya Rusanova

[email protected]

Related Journal Article

http://dx.