This study is led by Prof. Zhen Zhao (State Key Laboratory of Heavy Oil Processing, China University of Petroleum, College of Chemistry and Chemical Engineering, Shenyang Normal University), Dr. Lian Kong (College of Chemistry and Chemical Engineering, Shenyang Normal University) and Dr. Bing Liu (Department of Chemical Engineering, School of Chemical and Material Engineering, Jiangnan University). The catalytic performance was investigated using a fixed-bed reactor and the structure-activity relationship was studied by combining various characterizations with DFT calculations.

Credit: ©Science China Press

This study is led by Prof. Zhen Zhao (State Key Laboratory of Heavy Oil Processing, China University of Petroleum, College of Chemistry and Chemical Engineering, Shenyang Normal University), Dr. Lian Kong (College of Chemistry and Chemical Engineering, Shenyang Normal University) and Dr. Bing Liu (Department of Chemical Engineering, School of Chemical and Material Engineering, Jiangnan University). The catalytic performance was investigated using a fixed-bed reactor and the structure-activity relationship was studied by combining various characterizations with DFT calculations.

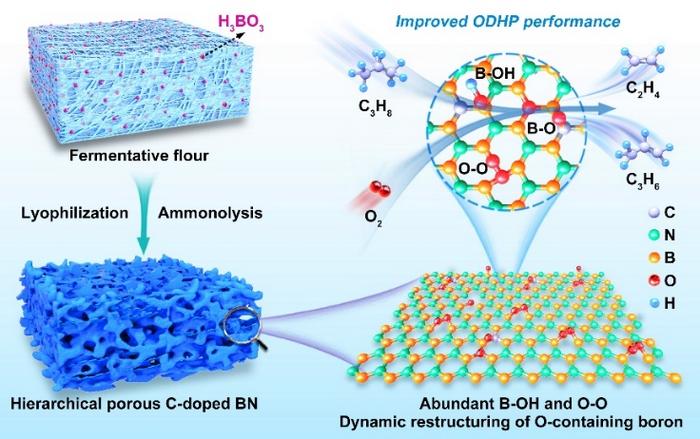

Interestingly, under the employed conditions the pore structure of the fermented flour was maintained, and the carbon incorporation also produced the abundance of oxygen-containing boron species in the BN framework. The catalytic performance of the porous CBN catalysts could be regulated by changing the flour dosage. The reactivity of the oxidative dehydrogenation of propane mainly depended on the specific surface area of P-CBN, pore structure and the interaction of oxygen-containing boron species.

“The oxidative dehydrogenation of propane to propylene (ODHP) is an exothermic reaction, which is not limited by the thermodynamic equilibrium transformation, has no carbon deposition and low operating temperature. It is considered as a promising alternative way for propylene production. However, propylene is easily deeply oxidized to COx due to the existence of oxidants, therefore, how to improve the selectivity and yield is a major challenge in ODHP process. Compared with metal-based catalysts, non-metallic BN material has been reported to have significantly better ODHP performance, but BOx groups on the BN surface plays a crucial role in obtaining high performance. Therefore, the regulation of the type and quantity of oxygen species in BN is a key to regulate its catalytic performance” Zhen says.

A few implications thus emerge for designing the BN-catalysts for the oxidative dehydrogenation of propane: 1) more oxygen-containing boron species are expected to be introduced into the BN framework for the activation of C-H bond in propane; 2) the incorporation of carbon atoms can promote the generation of B–OO–B species, and the presence of O2 is conducive to the recovery of B–O…O–B species during the reaction process. However, the excessive carbon can lead to the decrease of catalytic activity.

See the article:

Flour-derived borocarbonitride enriched with boron-oxygen species for the oxidative dehydrogenation of propane to olefins

https://doi.org/10.1007/s11426-023-1651-2

Journal

Science China Chemistry

DOI

10.1007/s11426-023-1651-2