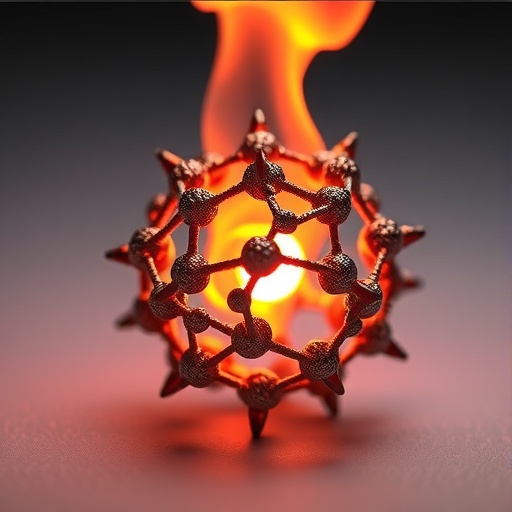

In recent years, the field of nanomaterials has been revolutionized by the burgeoning interest in high-entropy metal-containing systems. These materials, characterized by their complex, multi-elemental compositions, have opened new frontiers across various disciplines including catalysis, energy conversion, and advanced electronics. Traditionally, the synthesis of such materials demands rigorous conditions—particularly, elevated temperatures often exceeding 1,000 kelvin—to achieve the homogeneous mixing necessary for stable high-entropy phases. Despite their promise, current fabrication techniques typically involve cumbersome procedures and specialized, costly equipment, which limit their scalability and broader application. A recent groundbreaking study, however, has introduced a remarkably straightforward and versatile flame synthesis method, promising to overcome these challenges and expand the accessibility of high-entropy nanomaterials.

This novel flame-based synthesis operates on a deceptively simple principle: it harnesses the intense heat of burning hydrocarbons to drive the formation of high-entropy metal-containing nanostructures in situ. The process involves blending organometallic precursors directly into a hydrocarbon fuel source—in this case, paraffin wax—before combusting the mixture. As the fuel burns, the temperature in the flame reaches an estimated 1,800 kelvin, a sufficiently high thermal milieu to promote rapid and thorough mixing of multiple metal elements. This approach negates the need for complex reactors or atmosphere control, making it an accessible and scalable platform for fabricating high-entropy metallic materials supported on carbonaceous supports.

At the heart of this process lies the remarkable interplay between flame chemistry and material formation. The combustion of paraffin wax produces not just heat but also a reactive environment rich in carbon species, facilitating the concurrent formation of soot-like carbonaceous structures. These soot particles serve a crucial function: they act as a support matrix for the nucleation and growth of metal atoms and nanoparticles. The intimate association between metal species and carbon formed under these conditions is arguably a cornerstone of the method’s success. Such strong metal–carbon bonding stabilizes the metals on the carbon support, preventing aggregation and phase segregation, which are common hurdles in multi-metal systems.

.adsslot_8NFZ3AErgz{width:728px !important;height:90px !important;}

@media(max-width:1199px){ .adsslot_8NFZ3AErgz{width:468px !important;height:60px !important;}

}

@media(max-width:767px){ .adsslot_8NFZ3AErgz{width:320px !important;height:50px !important;}

}

ADVERTISEMENT

What sets this flame synthesis approach apart is its compositional flexibility. The researchers demonstrated the ability to incorporate up to 25 distinct metallic elements, ranging from transition metals to noble metals, within a single synthesized material. Perhaps more notably, the method achieves this compositional homogeneity irrespective of the metals’ thermodynamic compatibility—a perennial challenge in high-entropy alloy and nanomaterial design. Conventional synthesis routes often falter when constituents differ substantially in their reduction potentials, atomic sizes, or diffusion characteristics, leading to phase separation or uneven metal distribution. The rapid quenching and dynamic environment within the flame, however, appear to circumvent these issues by kinetically trapping the metals in a well-mixed, metastable configuration.

Beyond compositional uniformity, the method offers precise tunability over the chemical makeup of the resulting nanomaterials. By simply adjusting the initial blend of organometallic precursors, researchers can tailor the elemental ratio to achieve targeted material properties. This level of control is crucial as the performance of high-entropy materials—especially in catalytic applications—is deeply intertwined with their exact composition and atomic arrangement. Such versatile tunability paired with the speed and simplicity of flame synthesis paves the way for rapid discovery and optimization of next-generation catalysts and functional materials.

To showcase the practical potential of flame-synthesized high-entropy nanomaterials, the investigators evaluated their performance in electrocatalytic hydrogen peroxide (H₂O₂) synthesis, a reaction of immense interest due to the broad uses of H₂O₂ in environmental and industrial processes. Electrosynthesis of hydrogen peroxide from water and oxygen typically requires highly active and selective catalysts to be efficient and sustainable. The flame-derived high-entropy materials exhibited outstanding catalytic activity and stability, indicating that the unique multi-metallic configurations and strong metal–carbon interfaces generated by this synthesis route endow them with superior functional properties.

The implications of this work extend well beyond electrocatalysis. High-entropy materials are also hailed for their exceptional mechanical properties, corrosion resistance, and thermal stability, attributes that derive from their complex atomic landscapes. Producing such materials at the nanoscale, supported on conductive carbon, could unlock new strategies for energy storage devices, sensors, and even electronic components. The simplicity and scalability inherent to flame synthesis have the potential to democratize research and commercial adoption of these promising materials.

From a technological standpoint, the operational convenience of the flame process cannot be overstated. The use of widely available paraffin wax and organometallic precursors, combined with ambient pressure combustion, sidesteps the need for vacuum chambers, inert atmospheres, or multi-step annealing protocols. Consequently, this method may catalyze a paradigm shift in high-entropy nanomaterial fabrication by reducing entry barriers for laboratories without access to expensive, high-throughput facilities. Moreover, flame reactors can be engineered to handle continuous production, hinting at prospects for scalable industrial manufacturing.

The study also deepens our understanding of high-temperature reaction chemistry as it pertains to nanoscale metal formation. The kinetic mechanisms at play during flame synthesis—involving vaporization, nucleation, diffusion, and rapid quenching—shed light on how metastable, highly mixed metal phases can be locked into the solid state. This insight contributes to the broader field of materials science, particularly in unraveling the complex interplay between thermodynamics and kinetics in nonequilibrium synthesis pathways.

Importantly, the researchers meticulously characterized the flame-produced materials using an array of advanced microscopy and spectroscopy techniques. High-resolution imaging revealed atomically dispersed metal species alongside ultrasmall nanoparticles homogeneously distributed on carbon supports. Spectroscopic analyses confirmed the intimate metal-carbon interactions as well as the uniformity of elemental distributions, substantiating the hypothesized formation mechanisms. Such multi-dimensional characterization provides a robust foundation for correlating synthesis parameters with material structures and resulting functions.

The universality of this flame synthesis approach also lies in its adaptability across different metal systems. The authors demonstrated that both noble metals like platinum and gold, as well as earth-abundant transition metals such as iron, cobalt, and nickel, can co-exist seamlessly within the final nanomaterials. This freedom enables researchers to explore a vast compositional space in high-entropy materials science, unlocking combinations previously deemed impractical due to thermodynamic incompatibilities or synthetic complexities.

Future directions for flame-synthesized high-entropy metal nanomaterials may venture into tailored design for specific catalytic reactions, such as CO₂ reduction, nitrogen fixation, or oxygen evolution. The carbon-supported architecture offers intrinsic conductivity beneficial for electrochemical processes, while the high-entropy composition can introduce synergistic electronic effects and active site diversity. Additionally, integrating this method with other nanofabrication techniques could yield hierarchical structures with enhanced surface areas and catalytic sites.

In conclusion, this pioneering flame synthesis methodology emerges as a transformative advance, bridging the gap between the intricate chemistry of high-entropy alloys and the practical demands of scalable nanomaterial production. By leveraging simple combustion chemistry, it delivers compositionally tunable, highly homogeneous metal-containing nanomaterials embedded on conductive carbon, unlocking new avenues for scientific exploration and technological innovation. As the materials science community seeks routes to more sustainable and efficient catalysts and devices, such accessible and versatile approaches are poised to play a leading role.

Subject of Research: High-entropy metal-containing nanomaterials synthesis and electrocatalysis

Article Title: Flame synthesis achieves compositionally tailorable high-entropy metal-containing nanomaterials

Article References:

Liu, Z., Goudeli, E., Guo, R. et al. Flame synthesis achieves compositionally tailorable high-entropy metal-containing nanomaterials. Nat. Chem. (2025). https://doi.org/10.1038/s41557-025-01894-w

Image Credits: AI Generated

Tags: accessibility of high-entropy materialsadvanced nanomaterial fabricationcatalysis and energy conversioncombustion-driven nanomaterial creationflame synthesis methodhigh-entropy metal nanomaterialshigh-temperature synthesis techniquesinnovative material science solutionsmulti-elemental compositionsnovel synthesis approaches for nanostructuresorganometallic precursors in nanotechnologyscalable nanomaterials production