In order to create them, scientists from the University of Seville have used technology that is generally used to produce drops

Credit: Universidad de Sevilla

A group of researchers from the Higher Technical School of Engineering at the University of Seville have obtained filaments and fibres from highly viscous liquids with technology that is usually used to produce drops. By means of their research, they have discovered the conditions necessary for the formation of filaments with thicknesses of less than 50 micrometres (as a reference the thickness of a human hair is about 150 micrometres).

The experts have discovered that there is a moment at which a polymer in liquid state – specifically one that has been worked from polyethylene glycol, which is widely used in industry – shows greater elasticity that, instead of breaking up and forming drops, the liquid experiences a stretching which causes filaments to be formed. The generation process for these filaments is controlled by parameters like the molecular weight of the polymer and its concentration on the liquid, as well as the pressure that is used in the device.

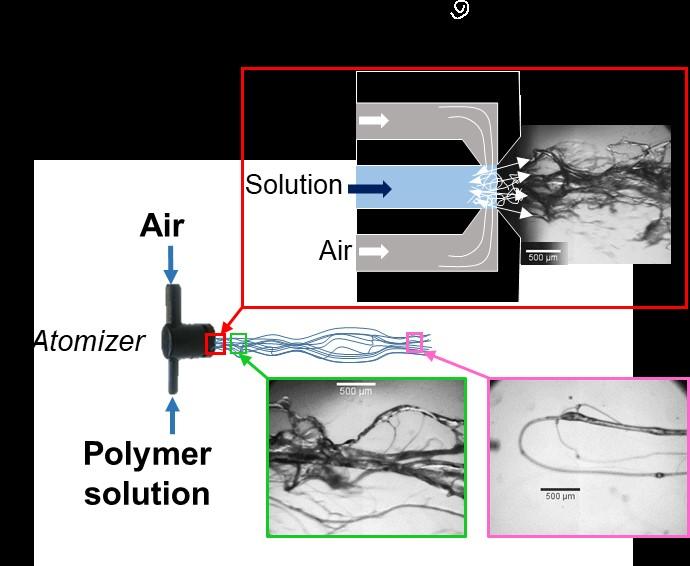

For this study, Flow Blurring technology was used. This technology, developed by the University of Seville professor Alfonso Gañán Calvo, is a highly efficient method for atomising liquid, called nebulisation.

This technology consists of using a current of air to break up a liquid and produce drops in the same way as the nebulisation systems that are used to refresh terraces in summer. Flow Blurring devices are very efficient because they channel the energy contained in the gas current for the generation of drops by means of vigorous mixing with the liquid, avoiding losses by other mechanisms. In addition, it has been shown that pneumatic Flow Blurring devices produce up to 50 times more surface area for each litre of nebulised liquid. This translates into drops that are up to 50 times smaller than when using other atomisers. This is due to the fact that Flow Blurring nebulisers concentrate the energy to such an extent that they are capable of atomising substances as viscous as paint, or as in this case, high-concentration polymer solutions.

“Using a high-speed camera, capable of recording a million images a second, we can observe that under certain conditions of use with Flow Blurring devices, polyethylene glycol solutions (and solutions of other polymers) do not form drops, but fragment into fine ‘threads’ that, when carried by an air current stretch out as they leave the atomiser. The diameter of these filaments is reduced, partly because polyethylene glycol is a shear thinning viscoelastic liquid. This means that when it stretches, it becomes less viscous, so that it becomes ever easier to stretch”, explains Luis Modesto López, University of Seville teacher and author of the study.

Polymer fibres at 3kg/hour

Polymers are macromolecules that are present in every area of modern life. Among the most common natural polymers are silk, cork, cellulose and starch. Synthetic polymers are generally found as coverings that provide specific functionality to materials, for example, by making them resistant to humidity or corrosion.

“In today’s world, there is great scientific and technological interest in the use of polymer fibres to make: frameworks for the design of artificial biocompatible materials, surfaces with antibacterial properties, materials for targeted drug delivery, protective textile materials that are capable of blocking some specific substances, or as reinforcement material. However, the manufacturing on an industrial scale of these materials means making them in great quantities. It is from this that our study takes on particular relevance as it provides a basis for developing a new process that will make it possible to produce filaments and polymer fibres at elevated levels, of the order of 3kg/hour using a simple nebuliser, while with the most common techniques in current use, they are produced at the rate of 1g/hour”, adds the researcher.

Another application could be in the field of 3D printing, given that what this technology does is manager a polymer. In addition, the study has a wide variety of applications in the field of Material Science, as it opens the doors to the production of an extensive variety of compound materials.

###

Media Contact

Luis B. Modesto Lopez

[email protected]

Original Source

https:/

Related Journal Article

http://dx.