In an era defined by the urgent imperative to curb global carbon emissions, the reverse water-gas shift (RWGS) reaction emerges as a pivotal route for efficient CO₂ utilization. Traditional thermal catalytic approaches to RWGS, however, suffer from high-energy demands and limited selectivity, constraining their commercial viability. A transformative breakthrough now materializes from the frontier of plasma-catalysis research. Recently published in Frontiers of Chemical Science and Engineering, a study reveals the formidable synergy achieved through combining non-thermal plasma (NTP) with a silver-doped zinc oxide (Ag/ZnO) catalyst, delivering unprecedented efficiency and selectivity in CO₂ conversion.

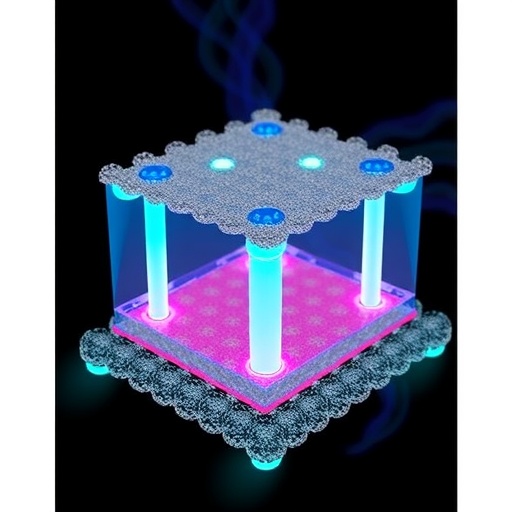

At the heart of this innovation lies a meticulously synthesized Ag/ZnO catalyst, fabricated via co-precipitation—a method known for producing uniform and highly active catalytic surfaces. When integrated into a dielectric barrier discharge (DBD) reactor, this catalyst system transcends the performance limits of plasma alone or plasma paired with bare ZnO. The detailed experiments showcase the plasma + Ag/ZnO combination achieving a striking near 76.5% conversion of CO₂, a quantum leap from the mere 21.8% conversion observed with plasma treatment absent the silver component.

The underlying mechanism driving this enhanced catalytic efficiency is rooted in intricate electronic metal-support interactions between silver nanoparticles and zinc oxide. Surface-sensitive analyses via X-ray photoelectron spectroscopy (XPS) and Auger electron spectroscopy (AES) reveal that the presence of silver induces electron-deficient sites, while concurrently generating partially reduced ZnO species. These unique electronic states modify the catalyst surface environment, substantially improving the adsorption and activation energies for both molecular hydrogen and CO₂ compared to standalone ZnO catalysts.

Further probing through temperature-programmed desorption (TPD) experiments confirms this heightened adsorption capacity. The Ag/ZnO catalyst exhibits superior affinity for adsorbing H₂ and CO₂ molecules, a precondition that fosters more intimate molecular activation and subsequent surface reaction kinetics. Such enhancements cannot be solely attributed to thermal effects but are ascribed to the plasma’s role in generating reactive radicals and excited species, which interact synergistically with the catalytic surface.

The novelty of this study stems from elucidating a dominant plasma-assisted surface reaction pathway. The electron-deficient silver sites facilitate the dissociation of molecular hydrogen, enabling a spillover effect where atomic hydrogen diffuses across the catalyst surface. Simultaneously, oxygen vacancies and reduced ZnOₓ species generated during plasma exposure create active centers for CO₂ adsorption and activation. This dual activation of reactants on proximate sites enhances the probability of subsequent surface-mediated reactions, culminating in the selective transformation of CO₂ into carbon monoxide (CO) with exceptional efficiency.

Crucially, the plasma-mediated approach operates at relatively mild temperatures, circumventing the thermal budget constraints inherent in conventional catalytic RWGS processes. The non-thermal plasma maintains the catalyst’s activation state by continually producing high-energy electrons and reactive species, thus sustaining catalytic activity without excessive heating. This advancement directly addresses the longstanding challenge of aligning high CO₂ conversion rates with energy-efficient operation.

Stability tests reinforce the promise of the Ag/ZnO plasma catalytic system, with sustained high performance demonstrated over a six-hour continuous operation period. Throughout this duration, the CO₂ conversion remains around 76.5%, while CO selectivity impressively hovers near 96.8%, highlighting the system’s robustness and potential for scalable deployment. Moreover, the energy efficiency metric—measured at 0.19 mmol·kJ⁻¹—represents a nearly four-fold increase over systems employing plasma alone or plasma with ZnO, underscoring the catalyst’s industrial relevance.

From a broader perspective, this research underscores the pivotal role of electronic metal-support interactions in tailoring surface environments to optimize catalytic performance under plasma conditions. The deliberate engineering of electron-deficient Ag sites paired with strategically induced oxygen vacancies introduces a new paradigm in catalyst design, shifting focus beyond traditional thermal pathways toward plasma-enabled surface chemistry.

The implications of this work extend beyond fundamental science into the realm of sustainable technology. Efficient plasma-assisted RWGS processes enabled by advanced catalysts such as Ag/ZnO offer a scalable avenue for converting captured CO₂ into syngas components under mild operation conditions. This synergy between catalysis and plasma technology paves the way for next-generation carbon management solutions, aligning with global efforts to decarbonize industrial processes and mitigate climate change.

Looking ahead, ongoing research inspired by these findings is poised to delve deeper into the mechanistic intricacies of plasma-catalyst interfaces. Further optimization of catalyst composition, plasma parameters, and reactor configurations will be critical to translating laboratory successes into pilot-scale systems. Integrating this approach with renewable energy sources could ultimately yield sustainable, carbon-neutral chemical manufacturing platforms.

This landmark study exemplifies the vital intersection of materials science, plasma physics, and catalytic chemistry. By leveraging cutting-edge experimental techniques and insightful surface characterization, the researchers have charted a compelling path forward for plasma-assisted CO₂ valorization. Their work not only broadens the scientific understanding of catalytic phenomena at plasma interfaces but also charts a promising course toward viable industrial applications that can confront the challenges of climate change.

Article Title: High CO2 conversion via plasma assisted reverse water-gas shift reaction over Ag/ZnO catalyst

News Publication Date: 5-Dec-2025

Web References: 10.1007/s11705-025-2588-4

Image Credits: HIGHER EDUCATION PRESS

Keywords

Chemistry, Non-thermal plasma, Reverse water-gas shift reaction, Ag/ZnO catalyst, CO₂ conversion, Plasma-catalysis, Electron-deficient sites, Oxygen vacancies, Catalyst design

Tags: advanced catalytic materials synthesisAg/ZnO catalyst developmentcarbon emissions reduction strategiesCO2 conversion technologiesdielectric barrier discharge reactorenergy-efficient CO₂ utilizationhigh selectivity CO₂ conversionnon-thermal plasma applicationsplasma-assisted catalysisreverse water-gas shift reactionsilver-doped catalystssurface-sensitive analysis techniques