An interdisciplinary team of University of Minnesota Twin Cities scientists and engineers has developed a first-of-its-kind, plant-inspired extrusion process that enables synthetic material growth. The new approach will allow researchers to build better soft robots that can navigate hard-to-reach places, complicated terrain, and potentially areas within the human body.

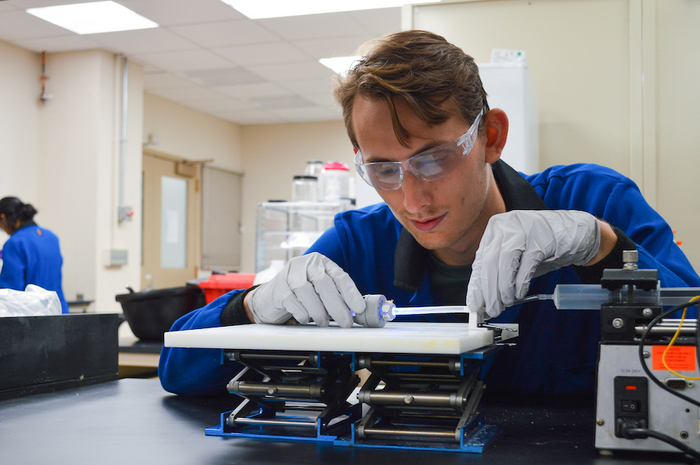

Credit: Olivia Hultgren

An interdisciplinary team of University of Minnesota Twin Cities scientists and engineers has developed a first-of-its-kind, plant-inspired extrusion process that enables synthetic material growth. The new approach will allow researchers to build better soft robots that can navigate hard-to-reach places, complicated terrain, and potentially areas within the human body.

The paper is published in the Proceedings of the National Academy of Sciences of the United States of America (PNAS), a peer-reviewed, multidisciplinary, high-impact scientific journal.

“This is the first time these concepts have been fundamentally demonstrated,” said Chris Ellison, a lead author of the paper and professor in the University of Minnesota Twin Cities Department of Chemical Engineering and Materials Science. “Developing new ways of manufacturing are paramount for the competitiveness of our country and for bringing new products to people. On the robotic side, robots are being used more and more in dangerous, remote environments, and these are the kinds of areas where this work could have an impact.”

Soft robotics is an emerging field where robots are made of soft, pliable materials as opposed to rigid ones. Soft growing robots can create new material and “grow” as they move. These machines could be used for operations in remote areas where humans can’t go, such as inspecting or installing tubes underground or navigating inside the human body for biomedical applications.

Current soft growing robots drag a trail of solid material behind them and can use heat and/or pressure to transform that material into a more permanent structure, much like how a 3D printer is fed solid filament to produce its shaped product. However, the trail of solid material gets more difficult to pull around bends and turns, making it hard for the robots to navigate terrain with obstacles or winding paths.

The University of Minnesota team solved this problem by developing a new means of extrusion, a process where material is pushed through an opening to create a specific shape. Using this new process allows the robot to create its synthetic material from a liquid instead of a solid.

“We were really inspired by how plants and fungi grow,” said Matthew Hausladen, first author of the paper and a Ph.D. student in the University of Minnesota Twin Cities Department of Chemical Engineering and Materials Science. “We took the idea that plants and fungi add material at the end of their bodies, either at their root tips or at their new shoots, and we translated that to an engineering system.”

Plants use water to transport the building blocks that get transformed into solid roots as the plant grows outward. The researchers were able to mimic this process with synthetic material using a technique called photopolymerization, which uses light to transform liquid monomers into a solid material. Using this technology, the soft robot can more easily navigate obstacles and winding paths without having to drag any solid material behind it.

This new process also has applications in manufacturing. Since the researchers’ technique only uses liquid and light, operations that use heat, pressure, and expensive machinery to create and shape materials might not be needed.

“A very important part of this project is that we have material scientists, chemical engineers, and robotic engineers all involved,” Ellison said. “By putting all of our different expertise together, we really brought something unique to this project, and I’m confident that not one of us could have done this alone. This is a great example of how collaboration enables scientists to address really hard fundamental problems while also having a technological impact.”

The research was funded by the National Science Foundation.

In addition to Ellison and Hausladen, the research team included University of Minnesota Department of Chemical Engineering and Materials Science researchers Boran Zhao (postdoctoral researcher) and Lorraine Francis (College of Science and Engineering Distinguished Professor); and University of Minnesota Department of Mechanical Engineering researchers Tim Kowalewski (associate professor) and Matthew Kubala (graduate student).

Watch a video of a soft growing robot navigating a tortuous path.

Watch a video explaining the idea behind the plant-inspired research.

Journal

Proceedings of the National Academy of Sciences

DOI

10.1073/pnas.2201776119

Method of Research

Experimental study

Article Title

Synthetic growth by self-lubricated photopolymerization and extrusion inspired by plants and fungi

Article Publication Date

9-Aug-2022