New process combines 3D laser lithography with microfluidics — publication in Science Advances

Credit: Figure: Frederik Mayer, INT/KIT

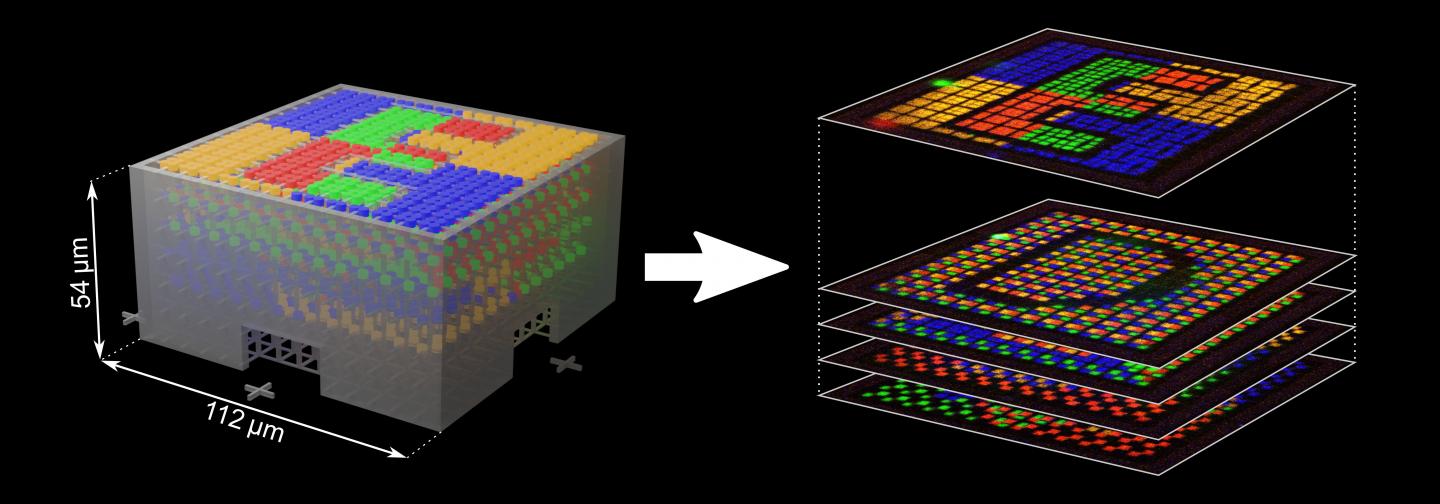

Three-dimensional structures on the micrometer and nanometer scales have a great potential for many applications. An efficient and precise process to print such structures from different materials is now presented by researchers of Karlsruhe Institute of Technology (KIT) and Carl Zeiss AG in Science Advances: they integrated a microfluidic chamber into a 3D laser lithography device. Then, they used this system to produce multi-colored, fluorescent security features to protect banknotes, documents, and branded products against counterfeiting. (DOI: 10.1126/sciadv.aau9160)

From components for data processing with light to optical microlenses, mechanical metamaterials, or artificial scaffolds for cell cultures to security features of banknotes or branded products, printed three-dimensional micro- and nanostructures have a large range of applications. 3D laser lithography has become an established, reliable, and versatile process for their production. A laser beam is passed through a liquid photoresist in a computer-controlled way and the material is exposed and hardened at the focal point of the laser beam only. This gives rise to highly precise filigree structures for many applications, including optics and photonics, materials sciences, biotechnology or security technology. Nearly all of the micro- and nanostructures produced by 3D laser lithography so far consist of a single material. But they might also be manufactured from several materials by successive application and hardening of different photoresists, with the unexposed resist being washed out in a subsequent developing bath. Such a process, however, is very time-consuming and complicated and its precision decreases with an increasing number of materials and repetitions.

Within the Cluster of Excellence “3D Matter Made to Order,” scientists of KIT’s Institutes of Nanotechnology (INT), of Applied Physics (APH), for Chemical Technology and Polymer Chemistry (ITCP), and of the School of Chemistry of Queensland University of Technology (QUT) in Brisbane/Australia, together with researchers of Carl Zeiss AG, have now developed a new system for the efficient and precise production of printed micro- and nanostructures from several materials. They integrated a microfluidic chamber for the fluids on smallest space directly into a 3D laser lithography device.

In their publication “Multimaterial 3D Laser Microprinting Using an Integrated Microfluidic System” in Science Advances, the researchers report that they used the integrated system to produce three-dimensional microstructured security features from seven different fluids: a non-fluorescent photoresist as backbone, two photoresists with different fluorescent quantum points, two photoresists with different fluorescent dyes, and two developer fluids. Such security features may protect banknotes, documents, and branded products against counterfeiting. A security feature consists of a three-dimensional lattice enclosed by retaining walls and fluorescent markers in different colors.

For their system, the scientists used a 3D laser lithography device developed and commercialized by Nanoscribe GmbH, a spinoff of KIT, and integrated it into a self-developed microfluidic chamber. It is provided with a cover glass of ten millimeters in diameter onto which the 3D structures can be printed. The chamber is connected to an electronic pressure control, up to ten containers for the different photoresists and developers, and a star-shaped selection valve. The fluid selected is passed to a specimen holder via an overpressure valve. Finally, it flows into a waste container. “All steps for producing three-dimensional micro- and nanostructures from several materials can be integrated into one system,” says Professor Martin Wegener, who heads the working group at APH. “This system paves the way towards multi-material additive manufacture on the micro- and nanoscale.”

###

Original Publication (Open Access):

Frederik Mayer, Stefan Richter, Johann Westhauser, Eva Blasco, Christopher Barner-Kowollik, Martin Wegener: Multimaterial 3D laser microprinting using an integrated microfluidic system. Science Advances, 8 February 2019. DOI: 10.1126/sciadv.aau9160

Being „The Research University in the Helmholtz Association”, KIT creates and imparts knowledge for the society and the environment. It is the objective to make significant contributions to the global challenges in the fields of energy, mobility and information. For this, about 9,300 employees cooperate in a broad range of disciplines in natural sciences, engineering sciences, economics, and the humanities and social sciences. KIT prepares its 25,100 students for responsible tasks in society, industry, and science by offering research-based study programs. Innovation efforts at KIT build a bridge between important scientific findings and their application for the benefit of society, economic prosperity, and the preservation of our natural basis of life.

This press release is available on the internet at http://www.

Media Contact

Monika Landgraf

[email protected]

49-721-608-21105

Original Source

https:/

Related Journal Article

http://dx.