In an era defined by an ever-expanding global population and intensifying demands for food resources, the imperative to enhance agricultural supply chains has never been greater. Fruits, as essential sources of nutrition worldwide, require precise grading and efficient processing to ensure both quality and food safety. Traditional fruit grading—reliant predominantly on human visual assessments—poses significant challenges, including labor intensiveness, susceptibility to human error, and inefficiency at scale. Addressing these limitations, a pioneering research team led by Dr. Muhammad Waqar Akram at the University of Agriculture Faisalabad, Pakistan, has unveiled an innovative machine vision-based automatic fruit grading system that promises to revolutionize the field. The results of this breakthrough study have been published in the respected journal Frontiers of Agricultural Science and Engineering.

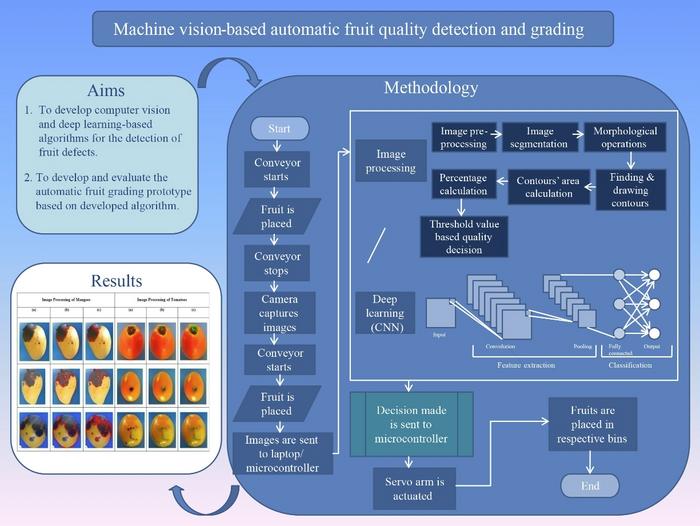

Central to this novel system is the seamless integration of machine vision technology with advanced deep learning algorithms. Through this fusion, the researchers have developed a fully automated pipeline—from defect detection on fruit surfaces to precise mechanical sorting—achieving rapid and reliable quality assessment. Fundamentally, the system mimics a digital photographic process, capturing detailed images of fruits as they move along a sorting line. The captured images are then analyzed in real-time to identify imperfections, after which a robotic sorting arm directs each fruit into the appropriate grade category. This multidisciplinary approach bridges cutting-edge computer vision with tangible, low-cost hardware components, tailored for practical deployment in farms and small to medium processing plants.

The backbone of this fruit grading system is its defect detection module, which employs a dual-track technical strategy to maximize accuracy and robustness. On one hand, the system uses classical image processing techniques that involve detailed image preprocessing, adaptive threshold segmentation, and morphological transformations. These steps quantify the proportion of defected areas on fruit surfaces with remarkable efficiency, ensuring rapid preliminary grading. On the other hand, the system incorporates convolutional neural networks (CNNs)—a stalwart in contemporary image recognition technology—to enhance defect identification. By training CNN models on diverse datasets consisting of publicly sourced images and real-world samples of mangoes and tomatoes under various ripeness and spoilage conditions, the system adapts expertly to the complex visual variability inherent in agricultural products.

.adsslot_MxerhXlH9U{ width:728px !important; height:90px !important; }

@media (max-width:1199px) { .adsslot_MxerhXlH9U{ width:468px !important; height:60px !important; } }

@media (max-width:767px) { .adsslot_MxerhXlH9U{ width:320px !important; height:50px !important; } }

ADVERTISEMENT

Experimental validation of the system demonstrates impressive detection performance. Traditional image processing algorithms achieved accuracies of 89% for mangoes and 92% for tomatoes, highlighting the effectiveness of these computationally light methods. However, the CNN-based deep learning model outperformed these results, reaching validation accuracies of 95% for mangoes and 93.5% for tomatoes. This significant increase in precision is critical for commercial applications, where grading consistency directly impacts market value, consumer satisfaction, and waste reduction. The capacity of deep learning to discern even subtle defects that evade simpler algorithms establishes a new benchmark in automated fruit quality evaluation.

Once defects are accurately detected, the system activates its mechanical sorting module through precise microcontroller commands, utilizing an Arduino Uno platform. The sorting apparatus consists of a conveyor belt synchronized with a servo motor-driven robotic arm capable of agile movements. As each fruit advances, the camera system captures images in the designated inspection area, feeding data to the analysis algorithm. If the analysis confirms defects beyond the preset thresholds, the sorting arm swiftly diverts the fruit into designated bins corresponding to its quality grade. This integration of imaging, computing, and electromechanics culminates in a streamlined process capable of completing grading and sorting within mere seconds per item—a transformative increase in throughput compared to manual methods.

A particularly noteworthy aspect of this innovative design is the complementary synergism achieved by combining traditional image processing with deep learning. Fast and cost-efficient, traditional algorithms excel in real-time performance scenarios, making them ideal for preliminary screening where immediate decisions are needed. Complementing this, deep learning algorithms capture nuanced features such as texture variations, color inconsistencies, and minor deformities that may impact fruit grade but are difficult to detect through threshold-based methods alone. The holistic approach ensures reliable operation even when faced with challenging conditions—including significant color heterogeneity on mango exteriors and complex surface textures present in tomatoes—thus enhancing the system’s versatility and generalizability.

Current practical applications of this system confirm its efficacy in grading mangoes and tomatoes—two globally significant fruits with distinct visual grading challenges. The research team envisions further advancements to enhance the system’s capabilities, including the addition of multi-angle camera setups to better capture fruit morphology and defect orientation. Moreover, expanding the technology’s applicability to a wider range of fruit species could profoundly impact postharvest handling and distribution sectors. Such developments could ultimately integrate with broader smart farming ecosystems, contributing to precision agriculture and sustainable food production goals.

The significance of this work extends beyond immediate fruit grading improvements. It exemplifies the transformative potential of deep learning and computer vision techniques when combined with traditional algorithms and mechanical automation. By addressing challenges at the intersection of agriculture, engineering, and artificial intelligence, the study paves new pathways for enhancing food quality and safety standards globally. As food value chains strive to meet the growing demands of a hungry planet, intelligent systems like these will be crucial to minimizing waste, improving market transparency, and safeguarding consumer health.

In summary, the machine vision-based automatic fruit grading system developed by Dr. Akram and his team represents a major stride toward intelligent, automated agriculture. Marrying fast classical image processing with the superior pattern recognition capabilities of convolutional neural networks, the system offers a reliable, efficient, and low-cost solution to the laborious task of fruit quality grading. Its rapid processing pipeline, mechanical sorting precision, and robustness against real-world variability position it as a promising advancement for agricultural industries worldwide. This innovation not only addresses persistent challenges in fruit grading but also sets a precedent for harnessing multidisciplinary technologies to meet future food security and sustainability demands.

This breakthrough in automatic fruit grading ultimately reflects a broader shift towards data-driven, precise agricultural processes that optimize resource use, reduce human error, and enhance product consistency. As the agricultural community and stakeholders worldwide grapple with impending food supply challenges, the implementation of such smart technologies offers a beacon of progress—highlighting how technological ingenuity can nurture both productivity and sustainability in the vital domain of food systems.

Subject of Research: Not applicable

Article Title: Machine vision-based automatic fruit quality detection and grading

News Publication Date: 6-May-2025

Web References:

https://journal.hep.com.cn/fase/EN/10.15302/J-FASE-2023532

http://dx.doi.org/10.15302/J-FASE-2023532

Image Credits: Amna1, Muhammad Waqar AKRAM1, Guiqiang LI2, Muhammad Zuhaib AKRAM3, Muhammad FAHEEM1, Muhammad Mubashar OMAR4, Muhammad Ghulman HASSAN1

Keywords: Agriculture

Tags: advancements in food processingagricultural supply chain innovationsautomated quality control in farmingautomatic fruit grading systemsdeep learning in agriculturedefect detection in fruitsenhancing food safety standardsmachine vision technologyprecision agriculture techniquesquality assessment in fruitreducing labor in fruit gradingrobotic sorting mechanisms