Calcium looping is an innovative carbon capture technique that addresses the persistent issue of greenhouse gas emissions from industries that are challenging to decarbonize. These sectors, particularly cement, steel, and glass production, account for substantial portions of global CO2 emissions but remain vital for societal needs. As governments and industries shift towards sustainability, carbon capture research becomes essential, especially in finding effective ways to mitigate emissions during the production of materials integral to modern infrastructure.

At the heart of calcium looping is a chemical process that captures CO2 emitted during the production of quicklime from limestone. The standard process, known as calcination, generates CO2 as a significant by-product, which subsequently enters the atmosphere. The traditional calcination process involves heating calcium carbonate to yield calcium oxide and carbon dioxide. Calcium looping reverses this reaction—utilizing calcium oxide to absorb CO2 from flue gases produced during cement manufacturing and other industrial processes. This not only curbs carbon emissions but also allows for the continual production of quicklime, harnessing it as a critical resource.

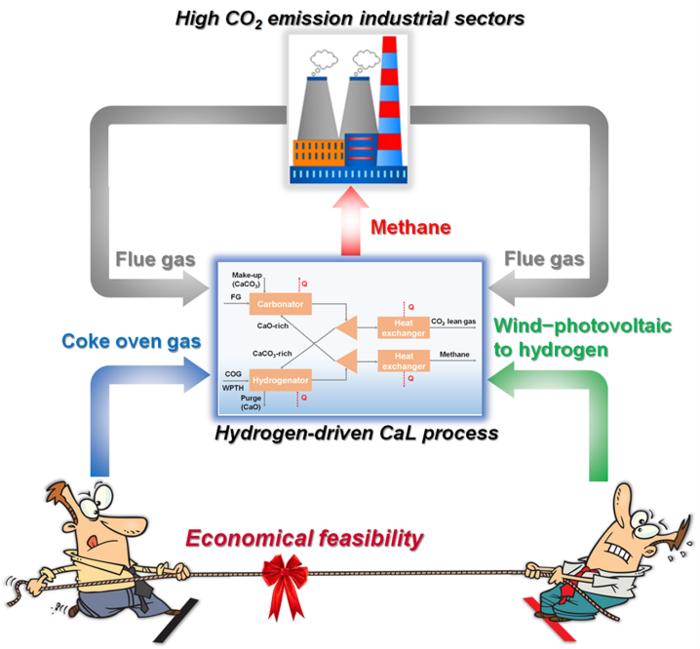

However, achieving success with calcium looping hinges on the availability of an effective hydrogen source to optimize the carbonation step of the process. Researchers in Guangzhou recognized the potential of hydrogen-driven calcium looping, where the presence of hydrogen can significantly boost the absorption efficiency of CO2 from various industrial emissions. The study meticulously analyzed two hydrogen sources, noting that while renewable hydrogen production is environmentally friendly, it currently faces economic drawbacks due to high production costs.

The advantage of coke oven gas is its abundance in regions where coal predominates in the chemical industry, like China. Coke oven gas, which consists of approximately 60% hydrogen, is generated from the heating of coal and is often wasted when not utilized for energy or feedstock in chemical processes. By harnessing this byproduct, researchers propose a transitional solution to carbon capture efforts while reinforcing the potential for hydrogen as a clean energy resource. The researchers used models to evaluate the performance of the two hydrogen sources, focusing on their efficiencies and profitability as they relate to calcium looping.

The analysis revealed that using hydrogen sourced from coke oven gas could generate about four times more synthetic methane compared to renewable hydrogen options and with significantly higher energy efficiency. Leveraging coke oven gas not only offers higher profitability—projected at around $26 million annually for hydrogen-driven calcium looping processes—but also addresses the pressing issue of reducing greenhouse gas emissions in the short term. In contrast, plants relying on renewably sourced hydrogen face substantial projected annual losses due to its currently high costs.

This study catalyzes a conversation about the role of transitional hydrogen sources in global decarbonization efforts. The researchers argue that while the coke oven gas route effectively addresses immediate economic and efficiency challenges, a long-term focus on renewable hydrogen will be indispensable for achieving net-zero greenhouse gas emissions. The transition towards cleaner hydrogen sources will require continued advancements in technology to lower production costs, alongside policy frameworks that promote the integration of such solutions in industrial applications.

While the path towards sustainable industry is fraught with challenges, the findings from this research emphasize the importance of leveraging available resources—such as coke oven gas—to facilitate a meaningful dialogue around the practical steps necessary for reducing industrial carbon footprints. The study serves as a reminder that, in the quest for a sustainable future, a careful balance of immediate practicalities and long-term vision will define the success of our endeavors towards carbon neutrality.

The insights derived from this research underscore the importance of collaborative efforts amongst industries, policymakers, and researchers. With the increasing demand for transparency and accountability in carbon emissions, establishing practical supply chains that utilize hydrogen derived from available resources emerges as a crucial step towards a sustainable economy. As industries grapple with their responsibility in climate change mitigation, the implementation of calcium looping powered by cost-effective hydrogen sources could provide a blueprint for the future.

This evolving narrative of hydrogen’s applicability highlights a crucial intersection of chemistry, economics, and environmental science. The dynamic evolution towards more sustainable practices showcases the remarkable potential of interdisciplinary research in transcending theoretical models into actionable solutions. Ultimately, the commitment to harnessing hydrogen as a clean energy source is as much a scientific endeavor as it is a societal imperative.

Subject of Research: Hydrogen-driven calcium looping for carbon capture

Article Title: Techno-economic analysis of hydrogen-driven calcium looping process for flue gas decarbonization

News Publication Date: 13-Dec-2024

Web References: Carbon Future Journal

References: Cement production sustainable concrete CO2 emissions

Image Credits: Credit: Carbon Future, Tsinghua University Press

Keywords

Hydrogen, calcium looping, carbon capture, coke oven gas, renewable energy, decarbonization, industrial processes, sustainability, synthetic methane, economic feasibility, greenhouse gas emissions, energy efficiency.