Credit: Vivek Polshettiwar

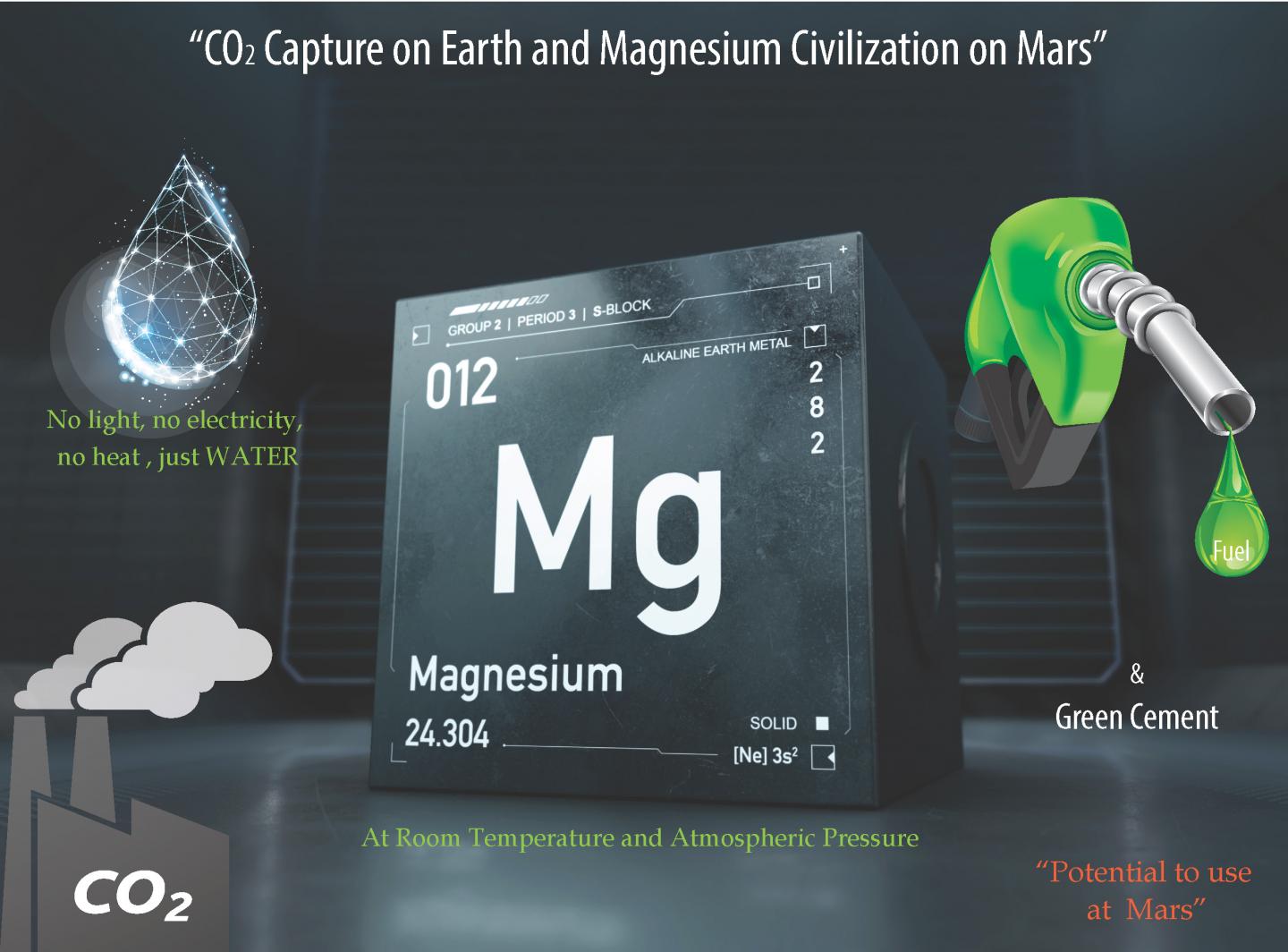

Excessive CO2 emissions are a major cause of climate change, and hence reducing the CO2 levels in the Earth’s atmosphere is key to limit adverse environmental effects. Rather than just capture and store CO2, it would be desirable to use it as carbon feedstock for fuel production to achieve the target of “net-zero-emissions energy systems”. The capture and conversion of CO2 (from fuel gas or directly from the air) to methane and methanol simply using water as a hydrogen source under ambient conditions would provide an optimal solution to reduce excessive CO2 levels and would be highly sustainable.

Researchers at Tata Institute of Fundamental Research (TIFR), Mumbai, demonstrated the use of Magnesium (nanoparticles and bulk) to directly react CO2 with water at room temperature and atmospheric pressure, forming methane, methanol, and formic acid without requiring external energy sources. Magnesium is the eighth most abundant element in the Earth’s crust and fourth most common element in the Earth (after iron, oxygen and silicon).

The conversion of CO2 (pure, as well as directly from the air) took place within a few minutes at 300 K and 1 bar. A unique cooperative action of Mg, basic magnesium carbonate, CO2, and water enabled this CO2 transformation. If any of the four components were missing, no CO2 conversion took place. The reaction intermediates and the reaction pathway were identified by 13CO2 isotopic labeling, powder X-ray diffraction (PXRD), nuclear magnetic resonance (NMR) and in-situ attenuated total reflectance-Fourier transform Infrared spectroscopy (ATR-FTIR), and rationalized by density-functional theory (DFT) calculations. During CO2 conversion, Mg was converted to magnesium hydroxide and carbonate, which may be regenerated.

Mg is one of the metals with the lowest energy demand for production and generates the lowest amount of CO2 during production. Using this protocol, 1 kg of magnesium via simple reaction with water and CO2 produces 2.43 liters of methane, 940 liters of hydrogen and 3.85 kg of basic magnesium carbonate (used in green cement, pharma industry etc.), and also small amounts of methanol, and formic acid.

In the absence of CO2, Mg does not react efficiently with water and hydrogen yield was extremely low, 100 μmol g-1 as compared to 42000 μmol g-1 in the presence of CO2. This was due to the poor solubility of magnesium hydroxide formed by the reaction of Mg with water, restricting the internal Mg surface from reacting further with water. However, in the presence of CO2, magnesium hydroxide gets converted to carbonates and basic carbonates, which are more soluble in water than magnesium hydroxide and get peeled off from Mg, exposing fresh Mg surface to react with water. Thus, this protocol can even be used for hydrogen production (940 liter per kg of Mg), which is nearly 420 times more than hydrogen produced by the reaction of Mg with water alone (2.24 liter per kg of Mg).

Notably, this entire production happens in just 15 minutes, at room temperature and atmospheric pressure, in the exceptionally simple and safe protocol. Unlike other metal powder, the Mg powder is extremely stable (due to the presence of a thin MgO passivation surface layer) and can be handled in the air without any loss in activity. The use of fossil fuels need to be restricted (if not avoided), to combat climate change. This Mg protocol will then be one of the sustainable CO2 conversion protocols, for a CO2-neutral process to produce various chemicals and fuels (methane, methanol, formic acid and hydrogen).

Planet Mars’ environment has 95.32% of CO2, while its surface has water in the form of ice. Recently, the presence of magnesium on Mars in abundant amounts was also reported. Therefore, to explore the possibility of the use of this Mg-assisted CO2 conversion process on Mars, researchers carried out this Mg-assisted CO2 conversion at a lower temperature. Notably, methane, methanol, formic acid and hydrogen were produced in a reasonable amount. These results indicate the potential of this Mg process to be used in the Mars’ environment, a step towards magnesium utilization on Mars, although more detailed studies are needed.

###

Media Contact

Vivek Polshettiwar

91-845-288-6556

Related Journal Article

http://dx.