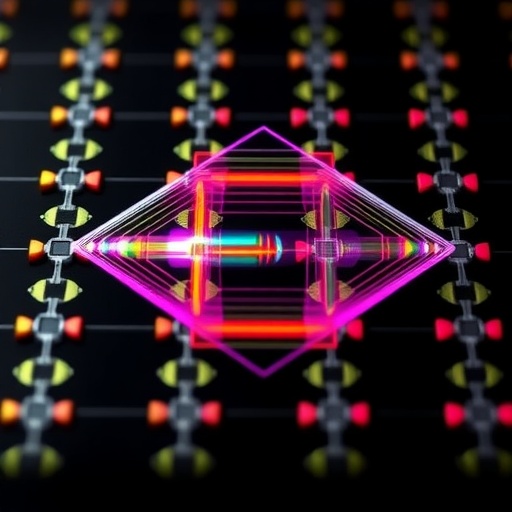

A groundbreaking advancement in optical technology has been achieved through the collaborative efforts of researchers at UCLA Samueli School of Engineering and the Optical Systems Division at Broadcom Inc. The team has developed a novel broadband, polarization-insensitive unidirectional imager that functions within the visible spectrum, heralding a new era of high-efficiency image transmission restricted to only one direction. This innovative device simultaneously suppresses image formation in the reverse direction, a feat long sought after in the realms of optical computing and imaging. The core of this development lies in the wafer-scale fabrication of multi-layer diffractive optical processors utilizing nanoscale lithography on high-purity fused silica substrates.

The technological leap here stems from the successful integration of diffractive structures engineered to manipulate visible light efficiently. These structures were realized through wafer-scale nano-fabrication techniques, characterized by their compatibility with existing semiconductor manufacturing processes. The use of fused silica as the substrate material provides exceptional optical transparency and thermal stability coupled with ultra-low optical loss, thereby ensuring consistent performance even in demanding operational conditions. This compatibility hints at a seamless potential for future integration with optoelectronic components, paving the way toward compact, high-performance imaging modules.

At the heart of the design process lies sophisticated deep learning-based inverse design, an emergent computational paradigm that optimizes nanophotonic structures by iteratively refining diffractive features for specific optical functionalities. Through this AI-driven approach, the researchers constructed multi-layered diffractive optical processors capable of directing visible light from an input field of view to an output field of view while effectively blocking or distorting reverse image paths. This represents the first ever experimental demonstration of broadband unidirectional imaging within the visible spectrum featuring nanoscale, polarization-insensitive features optimized by such machine learning techniques.

.adsslot_nlo1zSZyeA{width:728px !important;height:90px !important;}

@media(max-width:1199px){ .adsslot_nlo1zSZyeA{width:468px !important;height:60px !important;}

}

@media(max-width:767px){ .adsslot_nlo1zSZyeA{width:320px !important;height:50px !important;}

}

ADVERTISEMENT

One of the formidable challenges that limited previous designs was the fabrication complexity associated with nanoscale features in three-dimensional (3D) diffractive architectures. Conventional diffractive optics and metasurfaces primarily focus on two-dimensional implementations and operate at longer wavelengths where fabrication is more manageable. Overcoming these challenges, the researchers successfully implemented wafer-scale lithography processes capable of generating precise 3D multilayer diffractive optics with nanoscale resolution at visible wavelengths. This achievement is a testament to the maturation of modern nanofabrication technologies married with intelligent design algorithms.

The unidirectional imaging platform demonstrated here addresses the critical issue of reciprocity in optical systems, where signals typically traverse back and forth between input and output planes symmetrically. By engineering asymmetry at a nanoscopic scale within the diffractive layers, the device achieves high optical throughput in the forward direction while suppressing image fidelity in the reverse. This nontrivial manipulation of light propagation opens new avenues for security-enhanced imaging systems, where directional control can prevent unwanted reverse imaging and protect sensitive visual information.

From a materials science perspective, the choice of high-purity fused silica substrates cannot be understated. This material’s intrinsic properties – ultra-high transparency across the visible spectrum, resilience against thermal fluctuations, and minimal intrinsic absorption losses – synergize elegantly with the demands of high-performance diffractive optical processors. The multi-layer configuration of these processors exploits constructive and destructive interference of light within engineered nanostructures, crucially modulating the phase and amplitude of transmitted light to achieve the unidirectional effect.

The high-throughput nano-fabrication approach leveraged by the team is equally significant. Through wafer-scale lithography, which is traditionally employed in semiconductor manufacturing, the researchers demonstrated scalability and reproducibility of the nano-engineered optical devices. This ability to produce large-area, high-fidelity diffractive optical layers with nanoscale precision ensures that the technology is viable beyond research labs, ready for industrial adoption and mass production, thereby accelerating the dissemination of unidirectional visible imaging technologies.

This research also embodies a pivotal convergence of computational optics and hardware innovation. The deep learning algorithms driving inverse design do not merely automate the layout of nanostructures but actively optimize them for complex optical functions, including polarization insensitivity, broadband operational bandwidth, and unidirectional image transmission. Such computationally enhanced fabrication strategies are transformative, enabling the realization of optical systems previously deemed too challenging or impossible due to design and manufacturing constraints.

Potential applications for this technology are vast and compelling. Compact multispectral imagers can greatly benefit from incorporating unidirectional imaging processors, selectively transmitting desired spectral information while mitigating feedback and noise from unwanted directions. Furthermore, optical privacy protection stands as a critical domain where the unidirectional imager’s ability to distort reverse images can safeguard visual data from unauthorized observation, a feature that resonates deeply with the burgeoning demand for secure optical communications and surveillance deterrence.

This advancement holds profound implications for future developments in computational imaging and optical information processing. By synergizing nanoscale photonic engineering with AI-assisted design and scalable fabrication, the study charts a forward path for creating ultra-compact optical devices that are not only directionally selective but also robust, tunable, and integrable with electronic systems. Such devices could revolutionize how cameras, sensors, and optical networks function, leading to smarter, more secure, and efficient visual data acquisition and transmission.

The interdisciplinary nature of this work is underscored by its collaborative genesis, uniting experts from the UCLA Electrical and Computer Engineering Department, the California NanoSystems Institute at UCLA, and the Optical Systems Division at Broadcom Inc. This blend of academic rigor and industrial applicability ensures that the demonstrated technology not only pushes scientific boundaries but also aligns closely with real-world manufacturing and deployment needs, cementing its relevance and potential impact in the marketplace.

From a broader scientific perspective, this study exemplifies how the marriage of advanced materials, nanofabrication, and artificial intelligence can transcend traditional limits in optics. By establishing a versatile platform for wafer-scale nano-fabrication of multilayer diffractive optical processors, the researchers have unlocked new functionalities in visible light manipulation, setting a precedent for future innovations that exploit similar principles at other electromagnetic spectral regions or in more complex optical architectures.

In summary, the demonstration of broadband unidirectional visible imaging through wafer-scale nano-fabrication of multi-layer diffractive optical processors marks a seminal advancement in photonic engineering. It combines state-of-the-art fabrication, deep learning-powered design, and materials engineering to deliver a device capable of controlling light transmission directionally with high efficiency and spectral breadth. As this technology evolves, it promises to reshape fields from imaging and sensing to optical communications, heralding a new paradigm in how light can be harnessed and directed at the nanoscale.

Subject of Research: Broadband unidirectional visible imaging using nano-fabricated multi-layer diffractive optical processors.

Article Title: Broadband Unidirectional Visible Imaging Using Wafer-Scale Nano-Fabrication of Multi-Layer Diffractive Optical Processors

Web References: DOI link

Image Credits: Che-Yung Shen, Paolo Batoni et al.

Keywords

Unidirectional Imaging, Nano-Fabrication, Diffractive Optical Processors, Visible Spectrum, Wafer-Scale Lithography, Deep Learning Inverse Design, Polarization-Insensitive Optics, High-Purity Fused Silica, Optical Privacy Protection, Multispectral Imaging, Nanophotonics, Optical Computing

Tags: deep learning in optical designhigh-efficiency image transmissionhigh-purity fused silica substratesinnovative optical technology breakthroughsmulti-layer diffractive optical processorsnanoscale lithography techniquesoptical computing advancementsoptical transparency and thermal stabilitypolarization-insensitive imaging devicessemiconductor manufacturing compatibilityunidirectional visible imaging technologywafer-scale nano-fabrication