In the vast and dynamic field of polymer chemistry, the synthesis of carbon-carbon main chain polymers remains a cornerstone for creating materials that underpin countless industrial applications. Traditionally, vinyl polymerization has dominated this arena, facilitating the production of ubiquitous plastics such as polyethylene and polypropylene. This process hinges on the reactivity of the carbon-carbon double bond (C=C) in vinyl monomers, enabling the formation of a polymer backbone assembled from two-carbon units. However, a groundbreaking approach is now emerging from the laboratories of Ehime University, one that challenges the conventional paradigm by exploiting one-carbon (C1) polymerization methods. This novel strategy promises to unlock polymers with unprecedented structures and enhanced functionalities, propelled by the unique chemistry of monomers such as diazoacetates and sulfoxonium methylides.

Vinyl polymerization, while highly versatile and industrially prolific, restricts the placement of functional groups along the polymer backbone to every other carbon atom. Such spatial limitation inherently caps the density and potential interaction of functionalities, which directly influences the physical properties and reactivity of the resulting polymers. In contrast, C1 polymerization constructs the carbon chain from single-carbon building blocks. This subtle yet profound difference allows for the incorporation of functional groups at every carbon site along the polymer main chain. The resulting polymers, therefore, possess a higher concentration of functionalities, potentially giving rise to distinct chemical behavior and enhanced material properties.

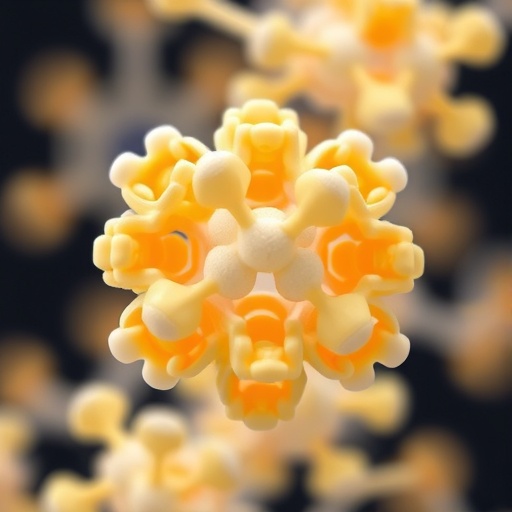

The exciting research conducted by the team at Ehime University pivots on the development of a new class of polymers termed “C1 cyclopolymers.” These polymers are crafted via cyclopolymerization—a process wherein polymerization proceeds concurrent with the formation of cyclic motifs embedded within the main chain. Prior efforts in C1 cyclopolymer synthesis primarily utilized bifunctional diazoacetates to fashion polymers in which each carbon atom participates in the cyclic framework. Such densely cyclic structures are hypothesized to impose unique conformational and intermolecular constraints that could dramatically influence thermal and mechanical characteristics.

A major barrier to broader exploration of C1 cyclopolymers has been the synthetic challenge in preparing bifunctional diazoacetate monomers with desired diversity. Conventional synthetic routes were limited in their ability to introduce structural variations and functional diversity, restraining the breadth of potentially accessible polymer architectures. Recognizing this shortfall, the Ehime University researchers set out to develop a versatile and efficient synthetic methodology that would expand the library of bifunctional diazoacetates and thereby enable systematic investigation of the impact of ring size and functional group placement on polymer properties.

Remarkably, the team employed pentaerythritol, a well-known polyhydric alcohol, as the central starting scaffold for monomer synthesis. This choice allowed for the modular construction of bifunctional diazoacetates bearing different ring sizes and functional moieties. By manipulating the derivatization of pentaerythritol, a variety of monomers featuring cyclic structures ranging from nine- to nineteen-membered rings were achieved. Additionally, incorporation of functional groups such as urethane linkages introduced potential sites for hydrogen bonding within the cyclic backbone, endowing the resulting polymers with opportunities for enhanced intermolecular interactions and potentially novel phase behaviors.

Subsequent C1 cyclopolymerization of these newly tailored monomers culminated in a family of C1 cyclopolymers with structural diversity and tunable properties. This synthetic success marks a significant advance, demonstrating that the stability and reactivity of these complex monomers can be harnessed to yield high molecular weight polymers. Importantly, the dense cyclic architecture imparts physical properties that sharply contrast with those of linear or randomly branched analogues.

Thermal analysis of these C1 cyclopolymers revealed significantly elevated glass transition temperatures compared to structurally analogous C1 polymers lacking cyclic motifs. This enhancement is indicative of restricted polymer chain mobility, likely a consequence of the highly ordered and compact cyclic structures embedded within the main chain. The presence of hydrogen-bonding urethane functionalities within the ring systems further contributes to thermal stability, as these interactions can act as physical crosslinks that limit segmental motion.

The implications of these findings are manifold. On a fundamental level, the ability to stitch together carbon-carbon main chain polymers from one-carbon units with precise cyclic frameworks introduces a new dimension in polymer design. This offers a pathway to architect polymers where every carbon contributes to a localized environment rich in functionality and steric regulation. From a materials science perspective, these advancements promise access to polymers with tailored thermal, mechanical, and potentially optical or electronic properties that surpass those available through traditional vinyl polymerization strategies.

Moreover, the versatility in ring size and functional group integration opens avenues for designing polymers suited to specific advanced applications. For instance, increased hydrogen bonding within cyclic backbones may translate into materials with superior self-healing capabilities, enhanced adhesion, or novel stimuli-responsive behaviors. The modularity of the synthetic approach also suggests that further functionalization and co-polymerization strategies could be explored, leading to an extensive repertoire of materials with bespoke properties.

This pioneering work conducted by the team at Ehime University not only challenges the status quo in polymer synthesis but also enriches the toolkit for chemists aiming to bridge molecular architecture with macroscopic properties. The presentation of these findings in the prestigious journal Macromolecules underscores the significance and transformative potential of this research in the field of polymer science.

As the scientific community continues to delve into these new frontiers, subsequent studies are anticipated to explore the mechanistic aspects of C1 cyclopolymerization in greater depth, alongside scaling and processing methodologies necessary for practical applications. Additionally, investigating the interplay between cycle size, functional group type, and polymer performance will shed light on the fundamental principles governing these novel materials.

In conclusion, the development of innovative synthetic methods for bifunctional diazoacetates and the successful C1 cyclopolymerization of these monomers herald a new chapter in polymer chemistry. Through these advancements, polymers with densely packed cyclic frameworks and fully functionalized main chains are now within reach, heralding materials that could redefine performance parameters in sectors ranging from packaging and coatings to high-performance composites and biomedical devices.

Subject of Research: Polymer chemistry; synthesis and properties of carbon-carbon main chain polymers via C1 cyclopolymerization.

Article Title: (Not explicitly provided in content)

News Publication Date: June 25, 2025

Web References: http://dx.doi.org/10.1021/acs.macromol.5c00704

References: Article published in Macromolecules, American Chemical Society, 2025.

Image Credits: Hiroaki Shimomoto, Makoto Ishimoto, Tomomichi Itoh, Eiji Ihara (Ehime University)

Keywords

Chemistry, Materials science

Tags: advanced materials developmentC1 polymerization methodscarbon-carbon backbone polymersdensely packed cyclic unitsEhime University researchenhanced polymer functionalitiesfunctional group incorporation in polymersindustrial applications of polymersinnovative polymer synthesis techniquespolymer chemistry breakthroughsunique monomer chemistryvinyl polymerization limitations