In the quest to create highly sensitive and reliable strain sensors, researchers have turned to nature’s intricate designs for inspiration. A groundbreaking study has unveiled an innovative omnidirectional strain sensor array that mimics the sophisticated architecture of a spider web. By harnessing this bioinspired configuration, the newly developed sensor array achieves remarkable performance in detecting strain magnitude and direction, opening new frontiers in advanced sensing technologies.

The spider web has long fascinated scientists and engineers due to its uniquely isotropic mechanical properties. Its radial and spiral threads distribute forces evenly, enabling the detection of multidirectional stresses with high sensitivity. Capitalizing on these natural characteristics, the research team devised a sensor array mimicking the web’s concentric and radial fiber layout, enabling omnidirectional strain detection—a capability that traditional linear or unidirectional strain sensors lack.

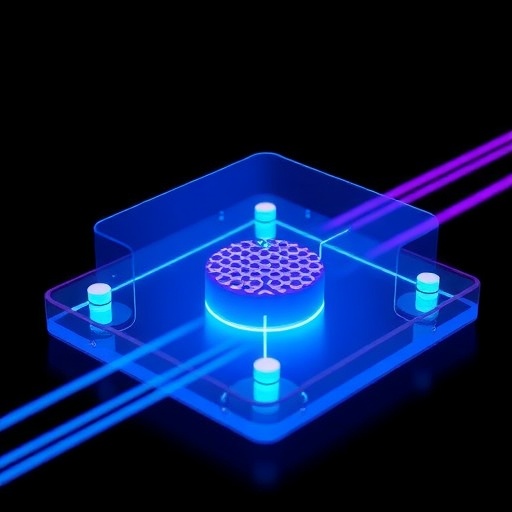

Central to this innovation is the use of Ti3C2Tx, a highly conductive material belonging to the MXene family. MXenes have emerged as promising candidates for flexible electronics due to their excellent electrical conductivity, mechanical flexibility, and surface chemistry. The team formulated a conductive ink from Ti3C2Tx flakes, which was then precisely deposited onto substrates using advanced 3D printing techniques. The combination of MXene’s superior properties and additive manufacturing allowed the fabrication of delicate sensor elements arranged in a bioinspired spider web pattern.

The fabrication process leverages 3D printing’s additive nature, enabling intricate geometries with high resolution and reproducibility. This method not only replicates the spider web’s complex weave but also ensures consistent sensor performance across the array. The printed sensor lines form interconnected pathways that respond to strain-induced deformation by altering their electrical resistance, a response that is then captured and interpreted.

Detecting strain in multiple directions poses a significant challenge because traditional sensors typically measure deformation along a single axis. The isotropic nature of the spider web design means the sensor array exhibits uniform sensitivity to strain regardless of direction, providing a rich dataset from complex mechanical stimuli. However, decoding such multidimensional signals requires sophisticated data processing to distinguish between strain magnitude and orientation.

To address this, the researchers integrated a multi-class, multi-output neural network model to perform signal decoupling. The neural network was trained to analyze electrical resistance changes across the entire sensor array and to infer the precise direction and magnitude of the applied strain. This approach transforms raw sensor data into actionable information, enabling accurate and real-time monitoring of complex mechanical interactions.

Experimental evaluation of the sensor array revealed a gauge factor (GF) of 26.3 within a strain range of 0 to 10%, which signifies a high sensitivity to strain-induced resistance changes. The gauge factor is a critical benchmark for strain sensors, representing the ratio of relative change in electrical resistance to mechanical strain. A high GF indicates the sensor can detect subtle strain variations, essential for applications requiring precise mechanical feedback.

Beyond sensitivity, the sensor array demonstrated exemplary accuracy in identifying strain parameters. Under various surface stimuli, the neural network achieved approximately 97% correctness in distinguishing both the magnitude and directional components of applied strain. This high classification accuracy is pivotal for applications such as wearable health devices and intelligent robotics, where precise motion detection and feedback are necessary.

One promising application for this bioinspired sensor technology lies in human motion monitoring. The human body produces complex, multidirectional strains during everyday activities, demanding sensors capable of capturing nuanced deformations. The spider web-inspired array’s isotropic sensing and robust decoding algorithm offer a significant advantage in wearable devices, facilitating detailed analysis of joint and muscle movements.

Moreover, the multifaceted strain detection ability can revolutionize smart robotic systems. Robots often require intricate tactile sensing and force feedback for precise manipulation tasks. Integrating such sensor arrays may enhance robotic skin, enabling machines to perceive multidirectional stresses and adjust their motions accordingly for safer and more efficient operation.

The research also underscores the reliability and repeatability of the sensor array’s performance. By combining the stable electrochemical properties of MXene materials with the robust architecture of the spider web pattern, the device maintains consistent responsiveness even after multiple cycles of mechanical deformation. This durability is crucial for real-world applications where sensors must operate under repetitive and dynamic loads.

Furthermore, the compatibility of the sensor fabrication process with flexible substrates and printing technologies suggests scalability and cost-effectiveness. Utilizing 3D printing allows rapid prototyping and customization, enabling tailored sensor designs for specific applications without the need for complex lithographic processes. This flexibility accelerates the translation of laboratory innovations into market-ready products.

In summary, this study effectively bridges natural biological structures with cutting-edge materials science and machine learning to realize an omnidirectional strain sensor array with exceptional sensitivity and signal processing capabilities. The integration of MXene conductive ink, spider web-inspired design, and neural network-based data decoupling forms a powerful platform for next-generation strain sensing technologies.

As wearable health monitoring devices proliferate and robotics advance toward more intuitive human-machine interactions, such sensor systems are poised to become indispensable. Their ability to accurately discern multifaceted mechanical signals promises to enhance device responsiveness, user experience, and safety across numerous fields. This research thus charts a promising path to multifarious applications in smart textiles, prosthetics, and interactive robotic skins.

The convergence of biomimicry, novel nanomaterials, additive manufacturing, and deep learning epitomizes future directions in sensor development. By drawing inspiration from something as deceptively simple yet functionally complex as spider webs, scientists have demonstrated how multidisciplinary approaches can resolve longstanding challenges in precision sensing, underscoring the profound insights nature continues to provide.

Subject of Research: Omnidirectional strain sensor array inspired by spider web structures using MXene-based conductive ink and neural network signal processing.

Article Title: (Not provided)

News Publication Date: (Not provided)

Web References: (Not provided)

References: (Not provided)

Image Credits: (Not provided)

Keywords: Omnidirectional strain sensor, spider web structure, MXene (Ti3C2Tx), 3D printing, neural network, signal decoupling, gauge factor, wearable sensors, intelligent robotics, flexible electronics.

Tags: 3D printing in sensor developmentadvanced sensing technologiesbioinspired sensor designconductive ink formulationflexible electronics applicationshigh-sensitivity strain sensorisotropic mechanical propertiesmultidirectional stress detectionMXene technologyomnidirectional strain detectionspider web architecturetwo-dimensional materials