A research team led by Dr. Jae-woong Ko from the Department of Engineering Ceramics at the Korea Institute of Materials Science(KIMS) has succeeded in localizing silicon nitride bearing ball manufacturing technology for electric vehicle drive modules. KIMS is a government-funded research institute under the Ministry of Science and ICT. This achievement is significant because it overcomes the limitations of foreign dependence and opens up the possibility of domestic supply and demand.

Credit: Korea Institute of Materials Science (KIMS)

A research team led by Dr. Jae-woong Ko from the Department of Engineering Ceramics at the Korea Institute of Materials Science(KIMS) has succeeded in localizing silicon nitride bearing ball manufacturing technology for electric vehicle drive modules. KIMS is a government-funded research institute under the Ministry of Science and ICT. This achievement is significant because it overcomes the limitations of foreign dependence and opens up the possibility of domestic supply and demand.

Silicon nitride bearing balls offer the advantage of preventing failures due to electric erosion in the high-power and high-speed rotational environments of electric vehicles. They also demonstrate high durability and reliability. However, there has been a persistent issue since these products have been exclusively imported from Japan. The supply of core components is of such paramount importance that the government is considering it a key policy to address the global supply chain reorganization in 2022, resulting from Japan’s exclusion of Korea from the whitelist in 2019. In the case of electric vehicles, both the automotive industry and manufacturers of finished bearing products concur that the supply and demand for bearing balls, a crucial material for parts that rotate at speeds exceeding 20,000 RPM, is not running smoothly.

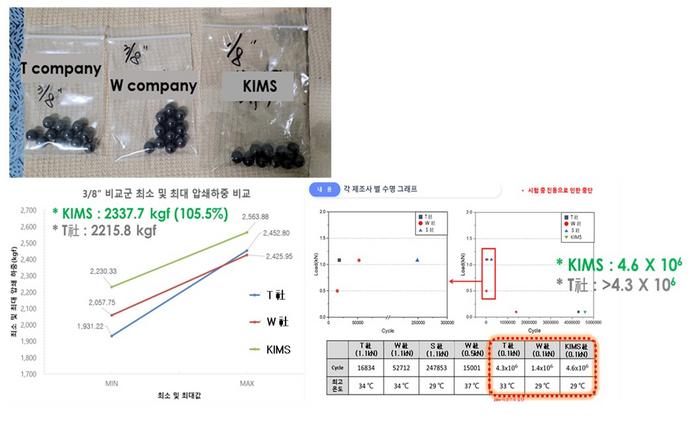

The research team has been developing technology to meet domestic demand, encompassing a range from silicon nitride raw material powder to materials and bearing ball parts. Subsequently, they conducted tests on the technology through external certified evaluation agencies and demand companies. They succeeded in achieving mechanical properties and life expectancy values closely aligned with those of T Company, the world’s leading silicon nitride bearing ball manufacturer. When evaluating T Company’s commercial balls and the research team’s manufactured balls under the same conditions, the crushing strength, which is a performance indicator for load-bearing capacity, demonstrated a comparative advantage of 103% to 105%. The rolling fatigue life, which is a performance indicator for withstanding high-speed rotation over an extended period, showed equivalent values.

Silicon nitride bearing balls are utilized in industries that require extreme operating conditions, including hybrid bearings rotating at high speeds in electric vehicle drive modules, bearings for wind turbines exposed to high loads, ultra-high-speed bearings for semiconductor process pumps, and bearings for space and aviation applications. The global market size of the hybrid bearing sector employing silicon nitride bearing ball technology was approximately KRW 1 trillion in 2022 and is expected to exceed KRW 1.3 trillion after 2026, driven by the rapid growth of the electric vehicle market.

Dr. Jae-woong Ko, responsible for developing this technology, said,“I believe we have established a bridgehead for securing our own supply chain that can meet the domestic demand for silicon nitride bearing balls through technology transfer to companies in the future.”adding, “We can expect not only an import substitution effect through local production, but also exports to overseas countries.

This research was conducted as part of the KIMS fundamental project ‘Development of ceramic rolling bearing materials for semiconductor high vacuum pump bearings’ funded by the Ministry of Science and ICT. Currently, the research team’s objective is to transfer this technology to domestic small and medium-sized companies with the necessary infrastructure and capabilities to mass-produce domestic ceramic materials and components. The goal is to secure a domestic supply chain for silicon nitride bearing balls and hybrid bearing supply chains through future mass production support.

————————————————————————-

###

About Korea Institute of Materials Science(KIMS)

KIMS is a non-profit government-funded research institute under the Ministry of Science and ICT of the Republic of Korea. As the only institute specializing in comprehensive materials technologies in Korea, KIMS has contributed to Korean industry by carrying out a wide range of activities related to materials science including R&D, inspection, testing&evaluation, and technology support.