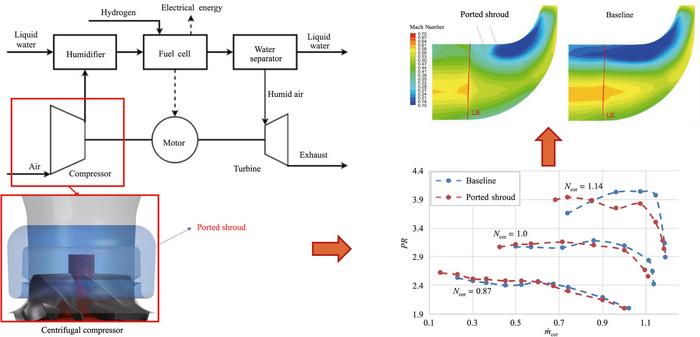

The automotive sector is navigating a pivotal transformation, shifting its focus from conventional internal combustion engines to cleaner, more sustainable propulsion technologies. Among the forefront of these innovations are proton exchange membrane fuel cells (PEMFCs), which promise superior efficiency alongside near-instantaneous response times. Realizing the full potential of PEMFCs, however, depends heavily on the integration of advanced turbocharging systems that ensure an optimal supply of compressed air to the fuel cell stack. Central to these turbocharging systems are centrifugal compressors, whose performance and stability dictate the effectiveness and reliability of fuel cell-powered vehicles. Yet, these compressors often struggle with instability near operational surge limits, a problematic phenomenon characterized by sudden flow reversals and pressure oscillations that can significantly impair compressor functionality.

Surge conditions in centrifugal compressors represent a critical operational boundary, beyond which flow separation and fluctuations emerge, sometimes causing damage or necessitating operational shutdowns. Conventional methods to expand compressor stability margins have included active control strategies and complex geometrical modifications, but these often involve increased system complexity or prohibitive costs. In recent years, passive flow control techniques, especially the implementation of ported shrouds, have garnered significant attention. Ported shrouds function by providing a controlled leakage path at the compressor’s outer casing, effectively redirecting problematic flow regions and enhancing stability. This approach offers an elegant and low-maintenance solution to mitigate surge phenomena and broaden the compressor’s usable operating range.

Crucially, the pressure ratio—the indicator of how much the compressor can elevate air pressure—increases notably near surge conditions when the ported shroud is employed. This reflects a tangible boost in system efficiency, permitting more consistent compressor output throughout demanding operating scenarios. Flow pattern analysis from the study highlights a fundamental shift in the relative flow angle at the rotor’s tip section. Essentially, the ported shroud alters the tangential velocity component, optimizing blade aerodynamics under the duress of near-surge flow regimes. This subtle rotation of flow vectors facilitates smoother rotor interaction with the working fluid, diminishing the likelihood of disruptive flow separations that precede surge.

Beyond the CFD insights, the research delivers a pioneering analytical model that predicts ported shroud performance across diverse geometric configurations without the computational intensity typical of full CFD runs. By calibrating this model against experimental baseline compressor data, engineers gain a powerful predictive tool to rapidly evaluate the efficacy of different cavity designs. This streamlined approach significantly truncates the product development cycle, allowing for accelerated prototyping and optimization of turbocharging components tailored for fuel cell applications. Industries benefit not only from cost reductions but also from enhanced agility in responding to evolving performance requirements.

The implications of this advancement transcend the fuel cell domain. The ported shroud technology’s potential extends to a broad spectrum of turbomachinery sectors—including industrial gas compressors and power generation gas turbines—where operational stability is paramount. Incorporating passive flow control strategies such as ported shrouds could lead to more robust machines exhibiting fewer maintenance demands and better operational economics. Moreover, the analytical framework devised could be generalized to model other flow control devices, fostering innovation and efficiency gains throughout compressor and turbine design disciplines.

Looking forward, a promising avenue lies in integrating adaptive control mechanisms with passive flow devices to create hybrid systems capable of dynamically tuning compressor performance in response to fluctuating operational conditions. Such systems could harness sensor data and real-time flow diagnostics to adjust port flow rates or geometric parameters, effectively expanding the active operating range even further while maintaining peak efficiency. These synergistic designs may mark the next frontier in turbomachinery technology, particularly in propulsion contexts where variable load demands are common.

The study underscores the growing importance of marrying high-fidelity numerical simulations with accessible analytical models to tackle longstanding fluid dynamic challenges in complex machinery. By distilling CFD results into actionable predictive tools, researchers and engineers can bridge the gap between theoretical innovation and practical application. This methodological fusion offers a blueprint for reducing design overhead while boosting system reliability—crucial factors for market-ready fuel cell turbochargers and beyond.

As global mobility paradigms pivot toward sustainable energy solutions, innovations such as ported shroud-enhanced centrifugal compressors will be pivotal in overcoming current technological barriers. The fuel cell industry, in particular, stands to gain substantially from turbocharger designs capable of maintaining stable, efficient compressor operation across widely varying engine loads and environmental conditions. This not only enhances vehicle performance and durability but also reinforces the broader adoption of hydrogen-based clean energy systems.

In conclusion, the development of analytical and computational tools to evaluate the influence of ported shrouds marks a significant milestone in turbomachinery research. The demonstrated improvements in surge margin enlargement and pressure ratio elevation signify meaningful strides toward more reliable, efficient fuel cell turbochargers. As this technology matures and proliferates across multiple applications, it exemplifies how targeted engineering innovations can accelerate the transition toward a cleaner, more sustainable automotive future.

—

Subject of Research: Not applicable

Article Title: Development of an analytical model to evaluate the effect of the ported shroud on centrifugal compressors

News Publication Date: 21-Feb-2025

Web References: http://dx.doi.org/10.1016/j.geits.2024.100249

References:

Author: Carlo Cravero, Philippe Joe Leutcha, Davide Marsano

Journal: Green Energy and Intelligent Transportation

DOI: 10.1016/j.geits.2024.100249

Image Credits: GREEN ENERGY AND INTELLIGENT TRANSPORTATION

Keywords

Fuel cells, Analytical chemistry

Tags: advanced ported shroud technologyautomotive propulsion technologiesCentrifugal compressor efficiencycompressor operational boundariescompressor surge stability issuesflow separation in compressorsfuel cell vehicle performanceinnovative compressor design solutionsoptimizing compressed air supplypassive flow control techniquesproton exchange membrane fuel cellsturbocharging systems for fuel cells