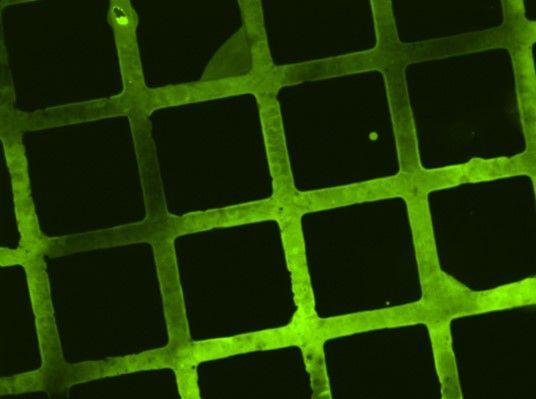

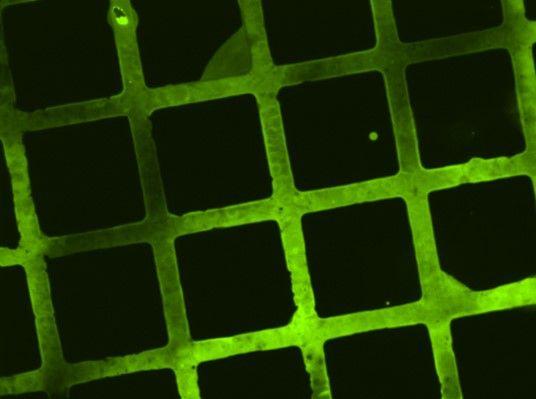

Credit: (Photo: KIT)

Medical implants often carry surface substrates that release ac-tive substances or to which biomolecules or cells can adhere better. However, degradable gas-phase coatings for degradable implants, such as surgical suture materials or scaffolds for tis-sue culturing, have been lacking so far. In the journal An-gewandte Chemie, researchers of Karlsruhe Institute of Technol-ogy now present a polymer coating that is degraded in the body together with its carrier. (DOI:10.1002/ange.201609307)

"Our new degradable polymer films might be applied for functionali-zation and coating of surfaces in biosciences, medicine, or food packaging," says Professor Joerg Lahann, Co-Director of the Insti-tute of Functional Interfaces of Karlsruhe Institute of Technology (KIT). Together with an international team, he produced polymer films with functional groups as "anchor sites" for fluorescent dyes or biomolecules.

For the first time, the researchers present a CVD (chemical vapor deposition) method to produce biodegradable polymers. Via spe-cial side groups, biomolecules or active substances can be at-tached. This opens up new potentials for e.g. coating biodegrada-ble implants. Polymerization by chemical vapor deposition is a sim-ple and widely used method to modify surfaces, by means of which also complex and irregular carrier substrates can be coated homo-geneously with polymers.

In CVD polymerization, the initial compounds are evaporated, acti-vated at high temperature, and deposited onto surfaces, where they polymerize. However, so far it has been possible to coat permanent implants only. Coating has been impossible for materials that are to be degraded after fulfilling their tasks, such as surgical suture mate-rials, systems for the controlled release of substances, stents re-leasing medical substances or scaffolds for culturing tissue. Bio-degradable coatings could not be produced by CVD.

Now, this gap is closed, as scientists of Karlsruhe Institute of Tech-nology, University of Michigan (Ann Arbor, USA), and Northwestern Polytechnical University (Xi'an, China) for the first time synthesized a CVD polymer with a degradable backbone. The team applied co-polymerization of two special monomer types: The para-cyclophanes usually used for this method were combined with cy-clic ketene acetals. While classical polymers on the basis of para-cyclophanes are linked by carbon-carbon bonds exclusively, ketene acetal is repositioned during polymerization, such that ester bonds (e.g. bonds between carbon and oxygen atoms) are formed in the polymer backbone. Ester bonds can be cleaved in aqueous medi-um.

"The degradation rate depends on the ratio of both monomer types and on the side groups of the monomers," Lahann explains. "Polar side groups make the polymer film less water-repellent and acceler-ate degradation, as water can enter more easily. In this way, the degradation rate can be adapted to application." Using cell cultures, the researchers already demonstrated that neither the polymer nor its degradation products are toxic.

###

Xie, F., Deng, X., Kratzer, D., Cheng, K. C. K., Friedmann, C., Qi, S., Solorio, L. and Lahann, J. (2016), Backbone-Degradable Poly-mers Prepared by Chemical Vapor Deposition. Angew. Chem. DOI:10.1002/ange.201609307.

Karlsruhe Institute of Technology (KIT) pools its three core tasks of research, higher education, and innovation in a mission. With about 9,300 employees and 25,000 students, KIT is one of the big institutions of research and higher education in natural sciences and engineering in Europe.

KIT – The Research University in the Helmholtz Association

Since 2010, the KIT has been certified as a family-friendly university.

Media Contact

Monika Landgraf

[email protected]

49-721-608-47414

@KITKarlsruhe

http://www.kit.edu/index.php

############

Story Source: Materials provided by Scienmag