Credit: ©Science China Press

The manufacturing sector is envisioned to be heavily influenced by artificial intelligence-based technologies with the extraordinary increases in computational power and data volumes.

Data-driven methods use sensor data, such as vibration, pressure, temperature, and energy data to extract useful features for diagnosis and prediction. A central challenge in manufacturing sector lies in the requirement of a general framework to ensure satisfied diagnosis and monitoring performances in different manufacturing applications.

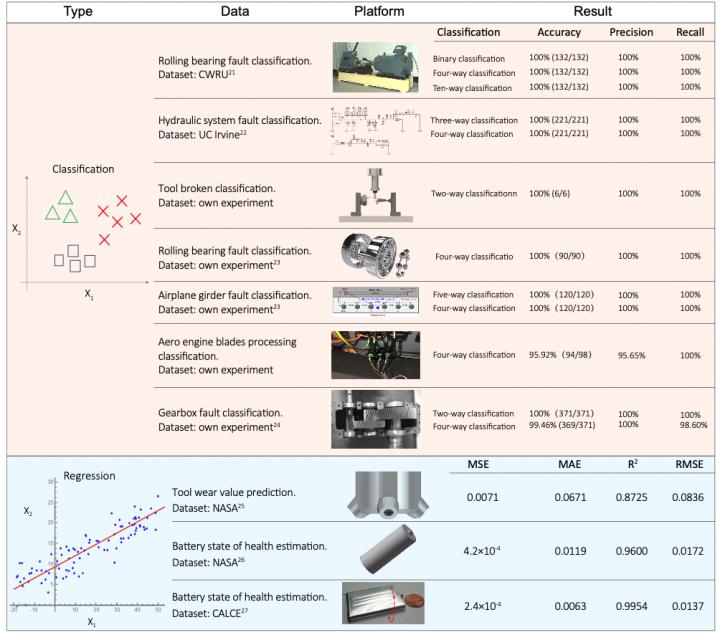

In a new research article published in the Beijing-based National Science Review, Prof. Ye Yuan from the School of Artificial Intelligence and Automation and Prof. Han Ding from the State Key Laboratory of Digital Manufacturing Equipment and Technology, Huazhong University of Science and Technology, jointly proposed an end-to-end diagnostic framework that can be used in diverse manufacturing systems. This framework exploits the predictive power of convolutional neural network to automatically extract hidden degradation features from noisy time-course data. The proposed framework has been tested on ten representative data sets drawn from a wide variety of manufacturing applications. Results reveal that the framework performs well in examined benchmark applications and can be applied in diverse contexts, indicating its potential use as a critical corner stone in smart manufacturing.

Considering that the potential time dependency existing among the reconstructed samples, this paper uses three standard cross-validation methods (random subsets, contiguous block, and independent sequence) to evaluate the performance of the framework. This paper also interprets how the CNN model learns from temporal manufacturing data and the robustness of the proposed framework is also discussed.

###

This research received funding from the National Natural Science Foundation of China (91748112 and 5135004).

See the article:

Ye Yuan, Guijun Ma, Cheng Cheng, Beitong Zhou, Huan Zhao, Hai-Tao Zhang, Han Ding,

A General End-to-end Diagnosis Framework for Manufacturing Systems

Natl Sci Rev 2019; doi: 10.1093/nsr/nwz190

https:/

The National Science Review is the first comprehensive scholarly journal released in English in China that is aimed at linking the country’s rapidly advancing community of scientists with the global frontiers of science and technology. The journal also aims to shine a worldwide spotlight on scientific research advances across China.

Media Contact

Ye Yuan

[email protected]

Related Journal Article

http://dx.