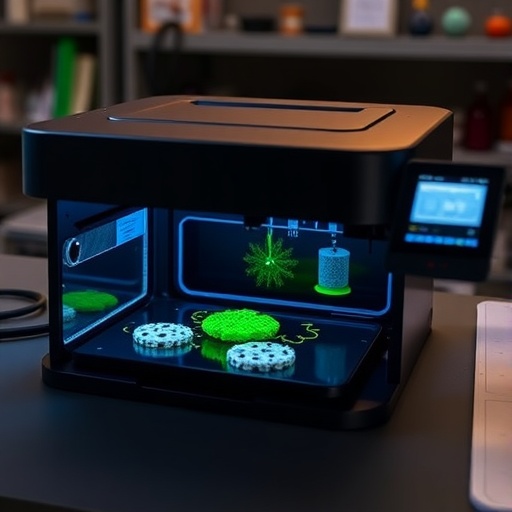

A groundbreaking advance in the field of regenerative medicine has emerged from the labs of UMC Utrecht and Utrecht University, promising to revolutionize 3D bioprinting through the integration of artificial intelligence and advanced imaging. The research team, led by Riccardo Levato, has developed GRACE, a novel volumetric bioprinting technology that not only constructs living tissues rapidly but also ‘sees’ and adapts in real time. This innovation addresses one of the most significant obstacles in tissue engineering: enhancing cell survival and function within printed living constructs.

Bioprinting traditionally involves the delicate process of depositing living cells layer by layer to build tissues and organs. However, this approach often leads to prolonged printing times and mechanical stresses that compromise cell viability. By contrast, volumetric bioprinting, the technique behind GRACE, harnesses light to solidify a photosensitive gel infused with cells all at once. This single-step curing process dramatically reduces exposure time and mechanical strain, preserving cell integrity while accelerating production from hours to mere seconds.

Central to the efficacy of volumetric bioprinting is a detailed understanding of the cellular distribution within the gel before and during printing. GRACE’s unique innovation lies in its capability to map this internal landscape using laser-based light-sheet imaging. This imaging modality, synchronized with the printer, allows real-time, high-resolution visualization of the cells dispersed inside the bio-ink. Unlike previous methods that relied on predefined blueprints detached from actual cell arrangements, GRACE leverages these live data to co-design the printed tissue structure dynamically.

This synergy of imaging and printing is empowered by state-of-the-art artificial intelligence algorithms capable of generating tailored vascular networks that align perfectly with the spatial organization of living cells. Functional blood vessels are indispensable for sustaining living tissue by ensuring sufficient nutrient and oxygen delivery. Traditionally, the challenge has been to anticipate where these vessels should be integrated without precise knowledge of cell positions. GRACE’s AI-driven design circumvents this by constructing an adaptive vasculature in real time, significantly improving tissue viability and function.

Beyond vascularization, GRACE’s intelligent system excels in multi-step printing processes. Complex tissues, such as bone overlain by cartilage, require sequential layering with impeccable alignment. GRACE automatically scans previously printed layers and generates exact fitting designs for subsequent layers, enabling seamless integration at volumetric printing speeds. This capability greatly simplifies a previously labor-intensive procedure, enhancing reproducibility and precision.

One of the less highlighted but equally critical challenges in volumetric bioprinting is light obstruction caused by printed components casting shadows. These shadows can weaken cross-linking efficiency, resulting in structural flaws. The GRACE system dynamically detects present obstacles through integrated imaging and correspondingly modulates the light projection patterns. This automatic compensation mechanism ensures uniform curing and superior construct integrity, opening avenues for embedding pre-fabricated objects such as stents within living printed tissues.

The technological architecture of GRACE is a sophisticated convergence of optics, robotics, and machine learning. It employs advanced laser optics to generate finely controlled light patterns that cure the gel with cell-friendly wavelengths. The imaging employs light-sheet microscopy principles adapted for volumetric scanning inside the rotating gel container. AI algorithms utilize generative models to synthesize optimal designs based on live imaging data, marking a paradigm shift where the printer also becomes an intelligent design partner rather than a passive manufacturing tool.

Despite these impressive technological feats, the translation of GRACE into clinical applications remains complex. The maturation of printed cells to achieve the full range of native tissue functionality is an ongoing challenge requiring further biological investigation. Nonetheless, the foundational capability of rapidly producing large-scale, cell-laden tissues with integrated vasculature presents unprecedented opportunities in tissue repair, drug testing, and ultimately, organ replacement.

Riccardo Levato and his team envision expanding GRACE’s scope to encompass printing of densely cellular tissues such as heart and liver, which require intricate vascular networks and high cell densities. Additionally, they aim to democratize this technology by making it accessible to other research groups worldwide, fostering an ecosystem of innovation around adaptive volumetric bioprinting and AI-assisted biomanufacturing.

This breakthrough represents a leap forward from static, blueprint-dependent bioprinting toward a responsive, context-aware fabrication process where the living material dictates structural formation. As 3D bioprinting moves closer to creating functional, transplantable organs, technologies like GRACE will become essential tools that blend computational intelligence with advanced optics to unlock new horizons in regenerative medicine.

The impact of GRACE extends beyond tissue engineering; it symbolizes the growing confluence of artificial intelligence and biofabrication, where machines not only execute but also understand and adapt to biological complexity. As research advances, such intelligent manufacturing platforms may redefine our approach to repairing and replacing human tissues, bringing personalized medicine closer to reality.

In sum, the development of GRACE is emblematic of the future of bioprinting: fast, precise, intelligent, and ultimately transformative. It offers a glimpse into a world where living tissues are fabricated on demand with the same sophistication and adaptability found in nature itself, potentially alleviating the global shortage of organ donors and ushering in a new era of patient-specific therapies.

Subject of Research: Adaptive and context-aware volumetric 3D bioprinting integrating AI-driven imaging for improved tissue fabrication

Article Title: Adaptive and context-aware volumetric printing

News Publication Date: 3-Sep-2025

Web References:

https://www.nature.com/articles/s41586-025-09436-7

https://research.umcutrecht.nl/researchers/levato/

https://research.umcutrecht.nl/stories/volumetric-bioprinting/

References:

Levato, R., Florczak, S., et al. (2025). Adaptive and context-aware volumetric printing. Nature, DOI: 10.1038/s41586-025-09436-7

Image Credits: Ivar Pel/UMC Utrecht

Keywords: Bioengineering, Health and medicine, Regenerative medicine, Tissue engineering, Computer vision, Artificial intelligence, Biomedical engineering, Biomaterials

Tags: AI in tissue engineeringartificial intelligence in bioprintingenhancing cell survival in printed tissuesGRACE technology for living tissueslight-sheet imaging applicationsovercoming challenges in organ printingphotosensitive gel for cell printingrapid tissue production techniquesreal-time adaptation in bioprintingregenerative medicine advancementsUMC Utrecht bioprinting researchvolumetric bioprinting technology