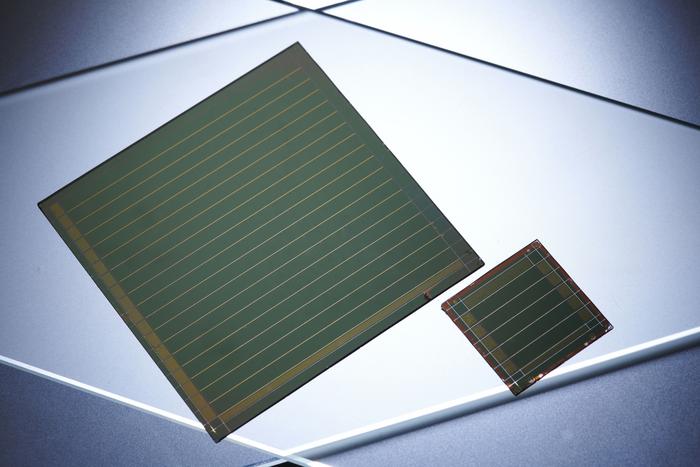

Perovskite tandem solar cells combine a perovskite solar cell with a conventional solar cell, for example based on silicon. These cells are considered a next-generation technology: They boast an efficiency of currently more than 33 percent, which is much higher than that of conventional silicon solar cells. Moreover, they use inexpensive raw materials and are easily manufactured. To achieve this level of efficiency, an extremely thin high-grade perovskite layer, whose thickness is only a fraction of that of human hair, has to be produced. “Manufacturing these high-grade, multi-crystalline thin layers without any deficiencies or holes using low-cost and scalable methods is one of the biggest challenges,” says tenure-track professor Ulrich W. Paetzold who conducts research at the Institute of Microstructure Technology and the Light Technology Institute of KIT. Even under apparently perfect lab conditions, there may be unknown factors that cause variations in semiconductor layer quality: “This drawback eventually prevents a quick start of industrial-scale production of these highly efficient solar cells, which are needed so badly for the energy turnaround,” explains Paetzold.

Credit: Amadeus Bramsiepe, KIT

Perovskite tandem solar cells combine a perovskite solar cell with a conventional solar cell, for example based on silicon. These cells are considered a next-generation technology: They boast an efficiency of currently more than 33 percent, which is much higher than that of conventional silicon solar cells. Moreover, they use inexpensive raw materials and are easily manufactured. To achieve this level of efficiency, an extremely thin high-grade perovskite layer, whose thickness is only a fraction of that of human hair, has to be produced. “Manufacturing these high-grade, multi-crystalline thin layers without any deficiencies or holes using low-cost and scalable methods is one of the biggest challenges,” says tenure-track professor Ulrich W. Paetzold who conducts research at the Institute of Microstructure Technology and the Light Technology Institute of KIT. Even under apparently perfect lab conditions, there may be unknown factors that cause variations in semiconductor layer quality: “This drawback eventually prevents a quick start of industrial-scale production of these highly efficient solar cells, which are needed so badly for the energy turnaround,” explains Paetzold.

AI Finds Hidden Signs of Effective Coating

To find the factors that influence coating, an interdisciplinary team consisting of the perovskite solar cell experts of KIT has joined forces with specialists for Machine Learning and Explainable Artificial Intelligence (XAI) of Helmholtz Imaging and Helmholtz AI at the DKFZ in Heidelberg. The researchers developed AI methods that train and analyze neural networks using a huge dataset. This dataset includes video recordings that show the photoluminescence of the thin perovskite layers during the manufacturing process. Photoluminescence refers to the radiant emission of the semiconductor layers that have been excited by an external light source. “Since even experts could not see anything particular on the thin layers, the idea was born to train an AI system for Machine Learning (Deep Learning) to detect hidden signs of good or poor coating from the millions of data items on the videos,” Lukas Klein and Sebastian Ziegler from Helmholtz Imaging at the DKFZ explain.

To filter and analyze the widely scattered indications output by the Deep Learning AI system, the researchers subsequently relied on methods of Explainable Artificial Intelligence.

“A Blueprint for Follow-Up Research”

The researchers found out experimentally that the photoluminescence varies during production and that this phenomenon has an influence on the coating quality. “Key to our work was the targeted use of XAI methods to see which factors have to be changed to obtain a high-grade solar cell,” Klein and Ziegler say. This is not the usual approach. In most cases, XAI is only used as a kind of guardrail to avoid mistakes when building AI models. “This is a change of paradigm: Gaining highly relevant insights in materials science in such a systematic way is a totally new experience.” It was indeed the conclusion drawn from the photoluminescence variation that enabled the researchers to take the next step. After the neural networks had been trained accordingly, the AI was able to predict whether each solar cell would achieve a low or a high level of efficiency based on which variation of light emission occurred at what point in the manufacturing process. “These are extremely exciting results,” emphasizes Ulrich W. Paetzold. “Thanks to the combined use of AI, we have a solid clue and know which parameters need to be changed in the first place to improve production. Now we are able to conduct our experiments in a more targeted way and are no longer forced to look blindfolded for the needle in a haystack. This is a blueprint for follow-up research that also applies to many other aspects of energy research and materials science.”

Original publication

Lukas Klein, Sebastian Ziegler, Felix Laufer, Charlotte Debus, Markus Götz, Klaus Maier-Hein, Ulrich W. Paetzold, Fabian Isensee, Paul F. Jäger: Discovering Process Dynamics for Scalable Perovskite Solar Cell Manufacturing with Explainable AI. Advanced Materials, 2023. DOI: 10.1002/adma.202307160

https://onlinelibrary.wiley.com/doi/10.1002/adma.202307160

Being “The Research University in the Helmholtz Association”, KIT creates and imparts knowledge for the society and the environment. It is the objective to make significant contributions to the global challenges in the fields of energy, mobility, and information. For this, about 9,800 employees cooperate in a broad range of disciplines in natural sciences, engineering sciences, economics, and the humanities and social sciences. KIT prepares its 22,300 students for responsible tasks in society, industry, and science by offering research-based study programs. Innovation efforts at KIT build a bridge between important scientific findings and their application for the benefit of society, economic prosperity, and the preservation of our natural basis of life. KIT is one of the German universities of excellence.

Journal

Advanced Materials

Article Title

Discovering Process Dynamics for Scalable Perovskite Solar Cell Manufacturing with Explainable AI

Article Publication Date

30-Oct-2023