In a significant leap for the field of material science, recent advances in machine learning are revolutionizing the way researchers model and understand additively manufactured meta-materials. This innovative approach melds complex mathematical techniques and artificial intelligence, offering unprecedented insights into the behavior and properties of these engineered materials. The compelling work led by Meynen, Kolken, Mulier, and their team explores the integration of machine learning into finite element modeling, showcasing how this combination dramatically enhances the effectiveness and efficiency of material design processes.

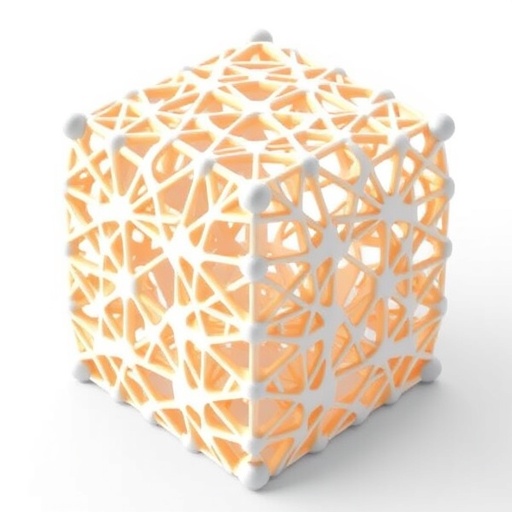

Additive manufacturing, often referred to as 3D printing, has emerged as a game-changing method for producing materials with highly complex geometries. Meta-materials, specifically designed with properties that do not occur naturally, have garnered attention due to their extraordinary capabilities, including negative refractive index and tailored acoustic properties. However, the complexity involved in modeling their intricate structures poses substantial challenges. Researchers have long sought reliable and efficient tools to predict how these materials will behave under various conditions.

The study primarily focuses on the application of machine learning algorithms to streamline the finite element modeling process. This method traditionally involves breaking down physical phenomena into smaller, manageable elements, yet it can become computationally intensive with the introduction of meta-materials. By utilizing machine learning techniques, the researchers aim to simplify this process, reducing the time and effort needed to achieve accurate simulations.

Central to their findings is the recognition that traditional modeling methods may overlook subtle relationships within the data that can be crucial for prediction. Machine learning offers the ability to uncover these patterns, enabling the development of more accurate predictive models that can foresee material behavior with remarkable precision. Leveraging existing datasets, the researchers employed supervised learning techniques, training algorithms to recognize and learn from previous modeling results.

An essential aspect of the research is the collaborative effort between experimental data collection and computational modeling. By integrating real-world testing with machine learning techniques, the team has developed a feedback loop that continuously refines the predictive models based on new experimental findings. This iterative process not only fortifies the accuracy of the models but also accelerates the design cycle for new meta-materials.

The implications of this research extend beyond mere academic inquiry; they hold the potential to reshape industries reliant on advanced materials. For instance, sectors such as aerospace, automotive, and biomedical engineering stand to benefit immensely from enhanced modeling techniques that allow for faster prototyping and manufacturing processes. Key to this success is the collaborative landscape that academia and industry must foster, ensuring that advances in machine learning translate effectively into practical applications.

In addition to the efficiency gains, another notable advantage of this machine learning-inclusive approach is its capability for personalization. With consumer demands increasingly focused on tailored solutions, the ability to swiftly adapt designs to meet specific requirements is invaluable. Meta-materials designed through these enhanced modeling techniques can be customized to optimize performance for specific applications, from shock absorption in automotive parts to soundproofing in architectural designs.

Machine learning also facilitates a shift towards more sustainable practices in material production. By optimizing the design process and reducing waste, the research champions an eco-conscious approach to manufacturing. The creation of meta-materials that outperform their traditional counterparts can lead to lighter, more durable products, directly impacting material consumption and energy efficiency throughout their lifecycle.

However, the journey toward fully realizing the potential of machine learning-assisted modeling is not without its challenges. The research team emphasizes the necessity for further exploration into the integration of various machine learning methods, as well as the need for comprehensive training datasets. As the technology evolves, the development of protocols to standardize data collection and sharing will be vital for fostering collaboration within the research community.

As this innovative research unfolds, the authors remain optimistic about the future trajectory of machine learning applications in material science. They envision a collaborative framework that not only pushes the boundaries of existing technologies but also encourages a new generation of engineering solutions. The integration of advanced computational methods into traditional sciences is poised to unlock new pathways for innovation, enhancing our understanding of the capabilities and potential of meta-materials.

In conclusion, the significant advancement presented by Meynen and colleagues serves as a testament to the transformative power of merging machine learning with the traditional finite element modeling approach. As industries increasingly pivot towards the utilization of smart materials with bespoke capabilities, the outcomes of this research herald a new era of design and engineering, marked by speed, accuracy, and sustainability.

The implications of this work are broad-reaching and underline the importance of interdisciplinary collaboration in innovation. As researchers continue to refine these methods, the line between theoretical exploration and practical application will increasingly blur, paving the way for breakthroughs that will define the future of engineering materials.

With the foundational knowledge laid out by this research, we can look forward to a robust future where machine learning not only enhances our modeling capabilities but also reshapes our understanding of material properties, ushering in new innovations that could change the fabric of modern technology.

Subject of Research: Machine learning-assisted finite element modeling of additively manufactured meta-materials

Article Title: Machine learning-assisted finite element modeling of additively manufactured meta-materials

Article References:

Meynen, A., Kolken, H., Mulier, M. et al. Machine learning-assisted finite element modeling of additively manufactured meta-materials.

3D Print Med 11, 36 (2025). https://doi.org/10.1186/s41205-025-00286-7

Image Credits: AI Generated

DOI: https://doi.org/10.1186/s41205-025-00286-7

Keywords: Machine Learning, Finite Element Modeling, Additive Manufacturing, Meta-Materials, Material Science, Predictive Modeling, Sustainability, Engineering Solutions.

Tags: 3D-printed metamaterialsadditive manufacturing techniquesadvanced mathematical techniquesAI-driven finite element modelingcomputational efficiency in modelingengineered materials behaviorinnovative material design processesintegration of AI in engineering.machine learning in material sciencemodeling complex geometriesnegative refractive index materialstailored acoustic properties