In a landmark advancement within the realm of energy storage technology, researchers from Nanjing University, under the guidance of Professors Ping He and Shaochun Tang, have unveiled a pioneering approach to fabricating high-energy, robust all-solid-state lithium batteries (ASSLBs). Their findings, slated for publication in the prestigious journal Nano-Micro Letters, detail the innovative utilization of aluminum-based anodes synergized with high-nickel cathodes—together providing a transformative path forward in the quest for more efficient and durable batteries suited to next-generation applications such as electric vehicles and aerial electric transport.

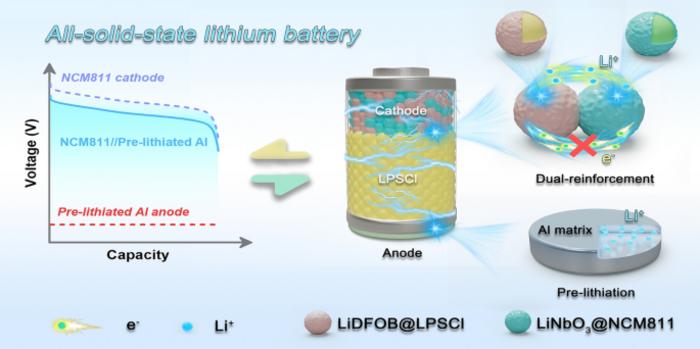

The state-of-the-art study directly addresses two persistent challenges that have long hindered the practical deployment of ASSLBs: the complex instability at the electrode–electrolyte interface and the retention of electrochemical performance over extended cycling periods. The researchers’ novel integration of pre-lithiated aluminum anodes with a dual-reinforced cathode structure ushers in a sophisticated interplay of materials engineering and electrochemical optimization, thereby setting a new benchmark for battery longevity and energy density in solid-state formats.

Fundamentally, the choice of aluminum as an anode material marks a significant departure from conventional lithium-metal anodes. Although lithium metal offers high theoretical capacity, it is plagued by dendrite formation and poor cycle life. Aluminum, by contrast, benefits from a naturally stable interface with sulfide solid electrolytes, derived from its intrinsic chemical compatibility and robust passivation characteristics. However, the intrinsic limitation of aluminum’s reversibility during lithiation-delithiation cycles previously restricted its widespread adoption. This hurdle has now been cleverly overcome by employing a precise anode pre-lithiation process, which effectively primes the aluminum surface to undergo stable electrochemical cycling with enhanced reversibility and interfacial integrity.

.adsslot_rWGhSiATdo{width:728px !important;height:90px !important;}

@media(max-width:1199px){ .adsslot_rWGhSiATdo{width:468px !important;height:60px !important;}

}

@media(max-width:767px){ .adsslot_rWGhSiATdo{width:320px !important;height:50px !important;}

}

ADVERTISEMENT

Simultaneously, the cathode side has undergone a profound transformation through the deployment of a high-nickel layered oxide chemistry. High-nickel cathodes are coveted for their superior specific capacity and elevated operating voltages, which jointly contribute to the enhancement of energy density metrics critical for practical energy storage systems. Yet, the high reactivity of nickel-rich materials with sulfide electrolytes historically precipitated deleterious interfacial degradation, undermining battery performance. To surmount this intrinsic incompatibility, the research team devised a sophisticated dual-reinforcement strategy. This approach utilizes surface coatings and interfacial engineering to stabilize the cathode–electrolyte boundary, thereby significantly augmenting the oxidative stability of the sulfide electrolyte under the high potentials imposed by nickel-rich cathodes.

The electrochemical performance metrics presented in this groundbreaking research are nothing short of impressive. The assembled batteries demonstrate remarkable cycling stability, maintaining over 82% of their initial capacity after 1000 charge-discharge cycles, a figure that testifies to the robustness and reversibility instituted by the pre-lithiation and dual-reinforcement tactics. This stability is achieved at a carefully engineered negative-to-positive electrode capacity ratio of 1.1, optimizing the balance to ensure both safety and performance. Additionally, the batteries reach a specific energy of approximately 375 Watt-hours per kilogram, situating them competitively alongside or even above current state-of-the-art liquid electrolyte lithium-ion batteries.

The implications of this study are profound for the advancement of ASSLBs as viable alternatives to traditional liquid electrolyte batteries, which suffer from safety concerns such as flammability and limited electrochemical windows. By leveraging solid-state electrolytes, the batteries inherently possess superior safety profiles, exhibiting enhanced thermal stability and resistance to dendritic short circuits. The researchers’ meticulous interface engineering thus mitigates the common trade-offs seen in solid-state systems between conductivity, stability, and energy density.

Another critical feature underscored by the study is the scalability potential of the synthesis protocols employed. Unlike certain niche laboratory techniques that preclude industrial adaptation, the methods for pre-lithiating aluminum anodes and fabricating dual-reinforced cathodes are amenable to upscaling. This scalability is essential for translating laboratory breakthroughs into practical commercial products capable of mass production. By bridging this gap, the research opens doors for the automotive and aerospace sectors to integrate these high-performance ASSLBs into electric vehicles and electric aircraft, where long-range energy storage and safety are paramount.

Despite the promising results, the authors acknowledge that further refinement remains necessary to fully harness the capabilities of ASSLBs. They emphasize the need for ongoing research focused on fine-tuning the microstructure of electrode materials, enhancing their intrinsic stability, and minimizing any residual interfacial resistance. Additionally, the exploration of hybrid and composite electrolyte systems, alongside advancements in manufacturing precision, is projected to further elevate battery performance and durability.

The fundamental insights gleaned from this study extend beyond mere performance metrics. By elucidating the delicate electrochemical and mechanical interactions at the electrode–electrolyte interface, the work offers a vital mechanistic framework that will inform the broader battery research community. This framework can be leveraged to engineer new materials and architectures marrying high capacity, long lifespan, and operational safety, crucial for powering future energy systems.

As the global energy landscape rapidly transitions towards electrification and sustainability, breakthroughs such as those emanating from Nanjing University underscore the critical role of materials innovation. The integration of aluminum-based anodes with high-nickel cathodes in solid-state configurations represents a paradigm shift, offering a compelling pathway to overcoming the longstanding limitations of lithium battery technologies. These advances herald a future where electric vehicles can travel farther, fly more efficiently, and energy storage solutions can be deployed safely at scale.

The ongoing research by Professors Ping He and Shaochun Tang promises to further unravel the nuances of interfacial chemistry and material compatibility, driving the optimization of ASSLBs. Their commitment to advancing this promising technology ensures that the potential of aluminum and nickel chemistries will be fully realized, paving the way for transformative impacts on energy storage in the coming decades.

In conclusion, this comprehensive study not only pushes the boundaries of battery technology but also elevates the scientific understanding of electrochemical interfaces in solid-state contexts. By combining practical engineering with fundamental science, it illuminates a path toward next-generation lithium batteries characterized by unprecedented energy density, safety, and cycling stability.

Subject of Research: Development of high-energy, stable all-solid-state lithium batteries using aluminum-based anodes and high-nickel cathodes.

Article Title: Developing High-Energy, Stable All-Solid-State Lithium Batteries Using Aluminum-Based Anodes and High-Nickel Cathodes

News Publication Date: 29-Apr-2025

Web References: DOI:10.1007/s40820-025-01751-y

Image Credits: Xin Wu, Meiyu Wang, Hui Pan, Xinyi Sun, Shaochun Tang, Haoshen Zhou, Ping He

Keywords

Energy; Batteries; Electrochemical cells; Solid-state lithium batteries; Aluminum anodes; High-nickel cathodes; Electrode-electrolyte interface; Battery cycling stability; Pre-lithiation; Dual-reinforcement technology

Tags: all-solid-state lithium batteriesaluminum anodes in batteriescycling stability in solid-state batteriesdendrite formation in batteriesdurable battery solutionselectric vehicle battery innovationelectrochemical performance optimizationenergy storage technology advancementshigh-nickel cathodesmaterials engineering in batteriesNanjing University battery researchnext-generation battery applications