As communication systems become increasingly demanding, integrated photonics stands at the forefront of technological advancements. Notably, thin-film lithium niobate (TFLN) has surfaced as a leading candidate for revolutionizing electro-optic applications due to its remarkable properties. This material’s ability to modulate light at unprecedented speeds and efficiencies positions it as a crucial component for next-generation communication technologies, paving the way for advancements in information processing and data transmission.

However, the road to harnessing the full potential of TFLN has been fraught with challenges, particularly regarding fabrication processes. Conventional methods, such as dry etching, have proven to be inadequate due to their inherent limitations. These techniques often result in low selectivity, inconsistent output across different manufacturing tools, and lengthy development cycles for processing recipes. Such obstacles not only hinder rapid prototyping but also complicate the mass production of devices made from novel materials like barium titanate (BTO). This scenario underscores the pressing need for innovative fabrication techniques that can streamline production and enhance the scalability of TFLN-based devices.

In response to these challenges, researchers have turned their attention to rib-loaded waveguide structures. These configurations utilize patterned ribs positioned atop thin films to efficiently guide light propagation. This approach theoretically circumvents some of the drawbacks associated with traditional fabrication techniques. Nevertheless, early implementations of rib-loaded waveguides have been met with significant difficulties, primarily due to the lack of appropriate rib materials. Conventional rib materials that share similar refractive indices with TFLN have been shown to divert a substantial amount of optical power away from the electro-optic layer. This power diversion results in diminished modulation efficiency, a critical parameter for operational success in high-speed communication systems.

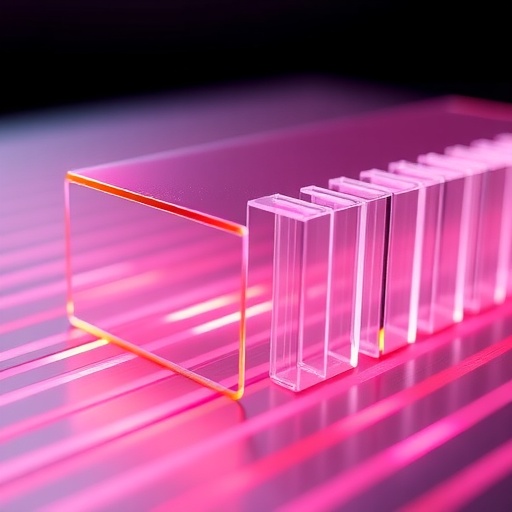

A groundbreaking development from the research community presents a promising alternative: the strong-confinement low-index rib-loaded waveguide structure. By employing low-index materials, such as silica, for the rib, this innovative design ensures that the transverse electric (TE) modes, which are crucial for maximizing electro-optic coupling, are effectively confined within the TFLN slab. The implications of such a structure are vast, as it eliminates the need for direct etching processes typically associated with thin films, thereby simplifying the overall fabrication workflow.

Professor Yang Li and his team from Sun Yat-sen University, in collaboration with Tsinghua University and AFR Ltd., have spearheaded research into this novel waveguide structure. Their findings are published in a study titled “Strong-confinement low-index-rib-loaded waveguide structure for etchless thin-film integrated photonics,” featured in the journal Opto-Electronic Advances. This research highlights the crucial advancements made in optimizing rib geometry, for instance, adjusting rib height, width, and TFLN film thickness, to achieve strong optical confinement. This meticulous optimization yields low propagation loss and significantly enhances electro-optic coupling for TE-polarized modes—a crucial factor in high-performance modulators.

One of the remarkable outcomes of the team’s efforts is the fabrication of an electro-optic modulator based on this strong-confinement waveguide structure. The device’s performance metrics are startling; it reaches a 3-dB bandwidth exceeding 110 GHz, while exhibiting a voltage-length product of merely 2.26 V·cm. These achievements not only rival existing etched TFLN modulators but also mark a radical simplification of the fabrication process. By sidestepping traditional etching requirements, the new approach holds immense potential for accelerating the deployment of TFLN-based devices in practical applications.

Moreover, the research team has laid the groundwork for additional passive optical components, such as Y-splitters and multimode interference couplers, utilizing the same waveguide concept. This versatility suggests that the strong-confinement rib-loaded waveguide structure could serve as a universal building block for a plethora of thin-film photonic integrated circuits. Its potential applications extend beyond mere light modulation; the structure embodies a more comprehensive framework for designing complex photonic devices capable of fulfilling diverse functionalities.

A significant aspect of this innovative structure is its ability to integrate rapidly emerging nonlinear materials such as BTO. This capability opens the door to the development of advanced photonic devices at a pace and cost-effectiveness previously unattainable. Such advancements are especially crucial in the realms of data communication, LiDAR systems, and quantum technologies, where the demand for faster processing speeds and higher efficiencies continues to rise.

The implications of these findings are far-reaching. The propagation of efficient, high-speed communication systems could vastly alter the landscape of data networks, improving not only the speed of information transmission but also the reliability of the systems that underpin modern technology. As more devices come online and the Internet of Things (IoT) continues to expand, the importance of robust communication channels cannot be overstated.

Professor Yang Li’s academic pedigree and his cutting-edge research signify a pivotal shift in how we approach photonic device fabrication. His extensive experience, combined with a team of talented researchers, cultivates a fertile ground for innovation in integrated photonics. The publication of their work not only highlights their immediate achievements but also positions them as leaders in the field, steering the future of photonic technologies toward rapid advancements that were once mere speculation.

As the research community grapples with the challenge of developing next-generation photonic devices, collaborative efforts such as those led by Professor Li are critical. The fusion of expertise from multiple disciplines—material science, electrical engineering, and optics—serves as a powerful reminder of the multifaceted nature of scientific discovery. The potential for this novel waveguide structure to impact various the domains of modern technology is profound.

Numerous researchers and engineers are keenly observing the trajectory of such innovations in integrated photonics, eagerly anticipating the next breakthrough. As industries increasingly rely on advanced photonic devices to enhance capabilities in communication, sensing, and beyond, the capability to manufacture these devices efficiently will determine the pace and success of technological advancement. The integration of strong-confinement rib-loaded waveguides stands as a beacon of innovation for future explorations in this rapidly evolving field.

In conclusion, the introduction of the strong-confinement low-index rib-loaded waveguide structure represents a significant leap forward in the realm of photonic device fabrication. By addressing existing limitations associated with conventional manufacturing techniques, this innovative approach not only optimizes device performance but also sets the stage for the rapid advancement of photonic technologies. As researchers continue to explore the vast potential of TFLN and related materials, the impact of such innovations will reverberate across countless domains, reshaping our understanding of integrated photonics for years to come.

Subject of Research: Strong-confinement low-index rib-loaded waveguide structure for thin-film integrated photonics

Article Title: Strong-confinement low-index-rib-loaded waveguide structure for etchless thin-film integrated photonics

News Publication Date: 27-Aug-2025

Web References: Link to Article

References: N/A

Image Credits: Yifan Qi, Gongcheng Yue, Yang Li

Keywords

Integrated photonics, thin-film lithium niobate, electro-optic modulators, strong-confinement waveguide, low-index rib, optical confinement, data communication, photonic integrated circuits, barium titanate, fabrication techniques.

Tags: advanced waveguide designadvancements in integrated photonics technologybarium titanate material integrationchallenges in photonics fabricationelectro-optic communication technologiesetchless photonics fabrication methodshigh-speed light modulationinnovative manufacturing techniques for TFLNnext-generation information processingrib-loaded waveguide structuresscalable photonics device productionthin-film lithium niobate applications