Increasing demands for power in modern microprocessors and artificial intelligence hardware have brought thermal management to the forefront of electronic system design. As these systems become more compact and power-dense, they inevitably approach thermal limits, resulting in a critical need for effective thermal interface materials (TIMs). TIMs are essential components that facilitate efficient heat dissipation, bridging the thermal gaps between different surfaces, and thus enhancing the overall thermal performance of devices. However, these materials encounter various real-world challenges that impede their effectiveness, including nanoscale surface roughness and imperfect contact interfaces, which can significantly increase thermal resistance.

The quest for efficient heat transfer using TIMs begins with understanding the fundamental mechanisms of thermal resistance at the interface between two dissimilar materials. Historically, heat transfer has been associated with conductive materials; however, at the microscale and nanoscale, even minute imperfections and surface roughness can lead to significant increases in interfacial thermal resistance. The dielectric properties and structural characteristics of TIMs play a crucial role, as they directly influence the material’s ability to conduct heat while maintaining mechanical stability. The interplay between thermal conductivity and mechanical compliance must be carefully balanced to achieve optimal thermal performance, particularly as device sizes shrink and power densities escalate.

As electronic devices evolve, the need for dynamic solutions to thermal management becomes increasingly apparent. Researchers have embarked on a journey to optimize TIMs, focusing on materials that can mitigate thermal resistance while simultaneously addressing the biological and environmental constraints associated with extreme operating conditions. Traditional materials, while effective, often fail to meet the rigorous demands of next-gen technologies. As such, innovation in TIM development is essential for ensuring the longevity and reliability of high-power electronic devices.

Recent advancements have introduced a diverse array of materials into the TIM landscape, including polymer-based compounds, metal matrix composites, and nanostructured materials. Each class of TIM possesses distinct characteristics that influence heat transfer efficiency. Polymers, for instance, offer flexibility and resilience, allowing them to conform to surface irregularities, yet they often fall short in terms of inherent thermal conductivity. In contrast, metal-based TIMs can provide exceptional heat transfer rates but may struggle with mechanical integration and flexibility. The challenge is to develop hybrid solutions that combine the best attributes of these materials, yielding a composite TIM that delivers both high thermal performance and mechanical compliance.

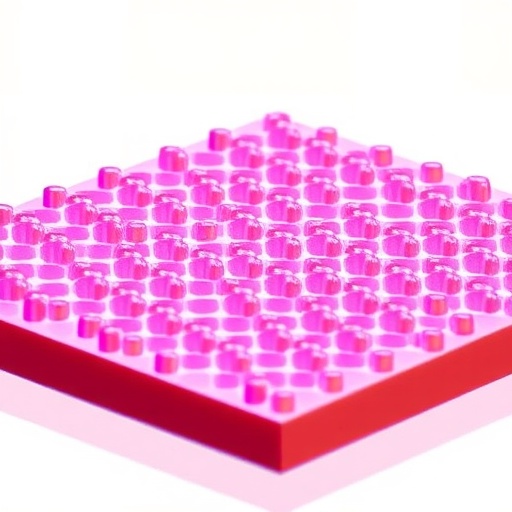

One promising approach under investigation involves the integration of nanomaterials into TIM formulations. Nanoscale fillers, such as carbon nanotubes or graphene, exhibit remarkable thermal conductivity and mechanical properties. When incorporated into TIMs, these fillers not only enhance thermal performance but also contribute to improved mechanical strength and adhesion. The development of such nanocomposite TIMs offers a pathway to significantly reduce thermal resistance while maintaining the necessary flexibility to accommodate expansion and contraction during thermal cycling.

Understanding and managing the thermal cycling that TIMs endure is pivotal for their long-term performance. Thermal cycling can lead to mechanical degradation, interfacial delamination, and changes in material properties that compromise thermal conductivity over time. Researchers are exploring various strategies to enhance the durability of TIMs under fluctuating thermal conditions. This includes developing materials that exhibit greater resistance to thermal fatigue and implementing design strategies that ensure uniform thickness and consistent contact across interfaces, thus minimizing potential failure points.

The future of TIMs lies not merely in selecting high-performance materials but in recognizing their role as integral components in the broader electronic system. As such, a co-design approach for TIMs and device architectures is gaining traction. This paradigm shift promotes collaborative development, where TIM selection, material properties, and interfacial design are considered alongside the electronic components they support. By treating TIMs as active participants in thermal management rather than passive fillers, designers can unlock new potentials in device efficiency and reliability.

Advancements in simulation and modeling also play a critical role in the future of TIM design. By employing advanced computational methods, researchers can predict thermal behaviors and optimize TIM architectures before physical prototypes are created. This approach allows for iterative testing and refinement, ensuring that the selected TIM will deliver maximum performance in real-world applications. The ability to accurately model thermal performance variations on a microscale will enable designers to make informed decisions about material selection, geometries, and bonding techniques.

As the race for higher power densities continues, the demand for effective thermal management solutions will only intensify. The electronic industry is poised for a transformative period where TIMs become a focal point for innovation. The development of advanced thermal interface materials can not only prolong the life of microprocessors and artificial intelligence systems but also catalyze breakthroughs in performance and efficiency. The integration of new materials and design strategies in TIM development heralds a new era for thermal management in electronics, paving the way for more powerful, reliable, and efficient devices.

In summary, as we stand on the brink of a technological revolution, the evolution of thermal interface materials will play a pivotal role in shaping the future of electronic systems. Researchers and engineers must embrace interdisciplinary collaboration to discover and integrate innovative materials and designs. Continuing to explore and develop TIMs as pivotal components of electronic architectures will be essential in addressing the challenges posed by no less than the hottest trends in technology.

Subject of Research: Development of thermal interface materials

Article Title: The development of thermal interface materials

Article References:

Dou, Z., Lei, C., Wu, K. et al. The development of thermal interface materials. Nat Electron (2025). https://doi.org/10.1038/s41928-025-01543-7

Image Credits: AI Generated

DOI: https://doi.org/10.1038/s41928-025-01543-7

Keywords: Thermal interface materials, electronic systems, heat dissipation, thermal resistance, nanocomposites, thermal cycling, material design, engineering framework.

Tags: artificial intelligence hardware coolingbalancing thermal conductivity and mechanical stabilitychallenges in thermal managementcompact electronic device designconductive materials in TIMsdielectric properties of thermal interface materialsefficient heat transfer in electronicsmicroprocessor thermal performancenanoscale thermal resistanceoptimizing thermal performance in power-dense systemssurface roughness effects on heat dissipationthermal interface materials advancements