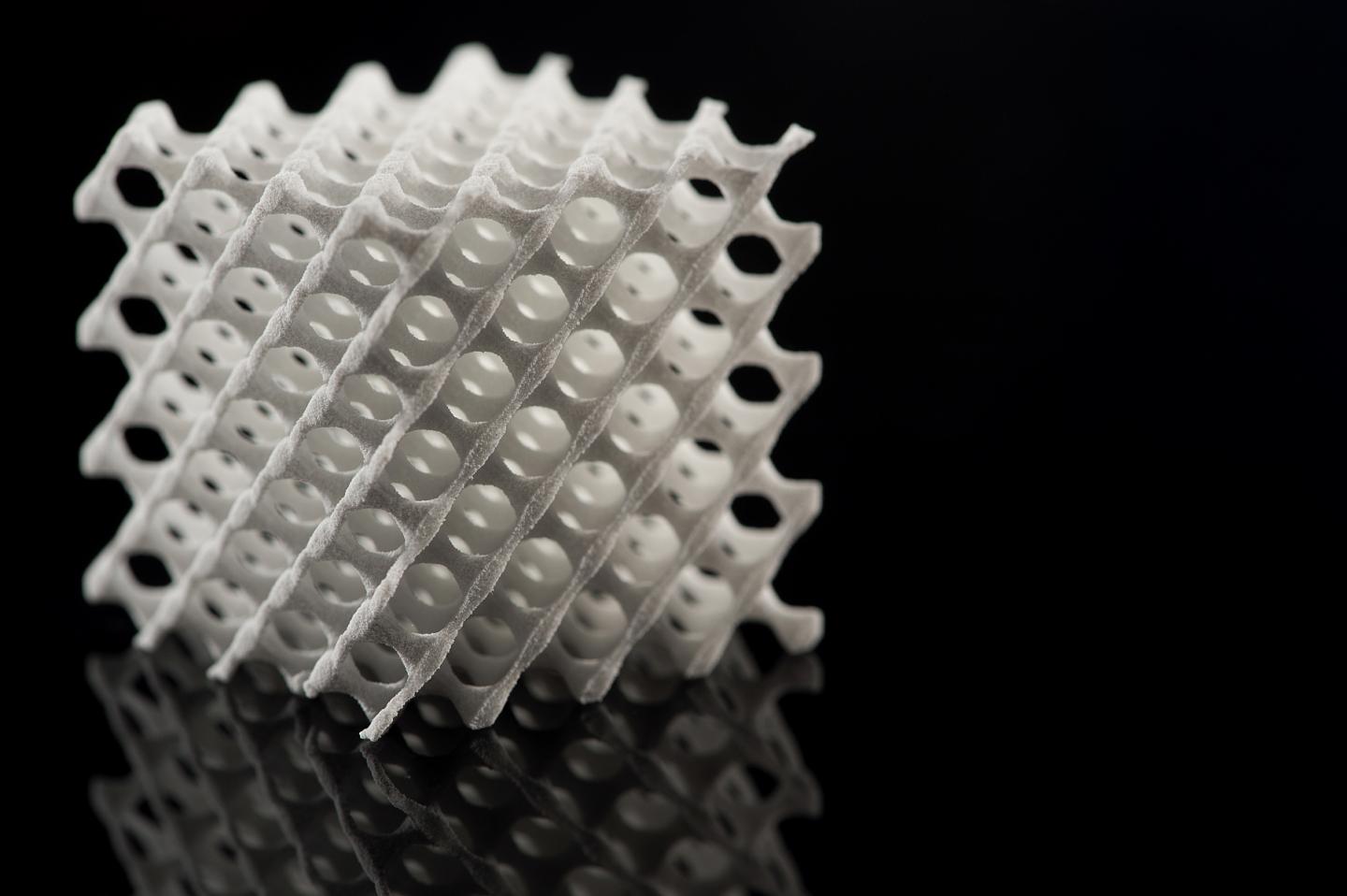

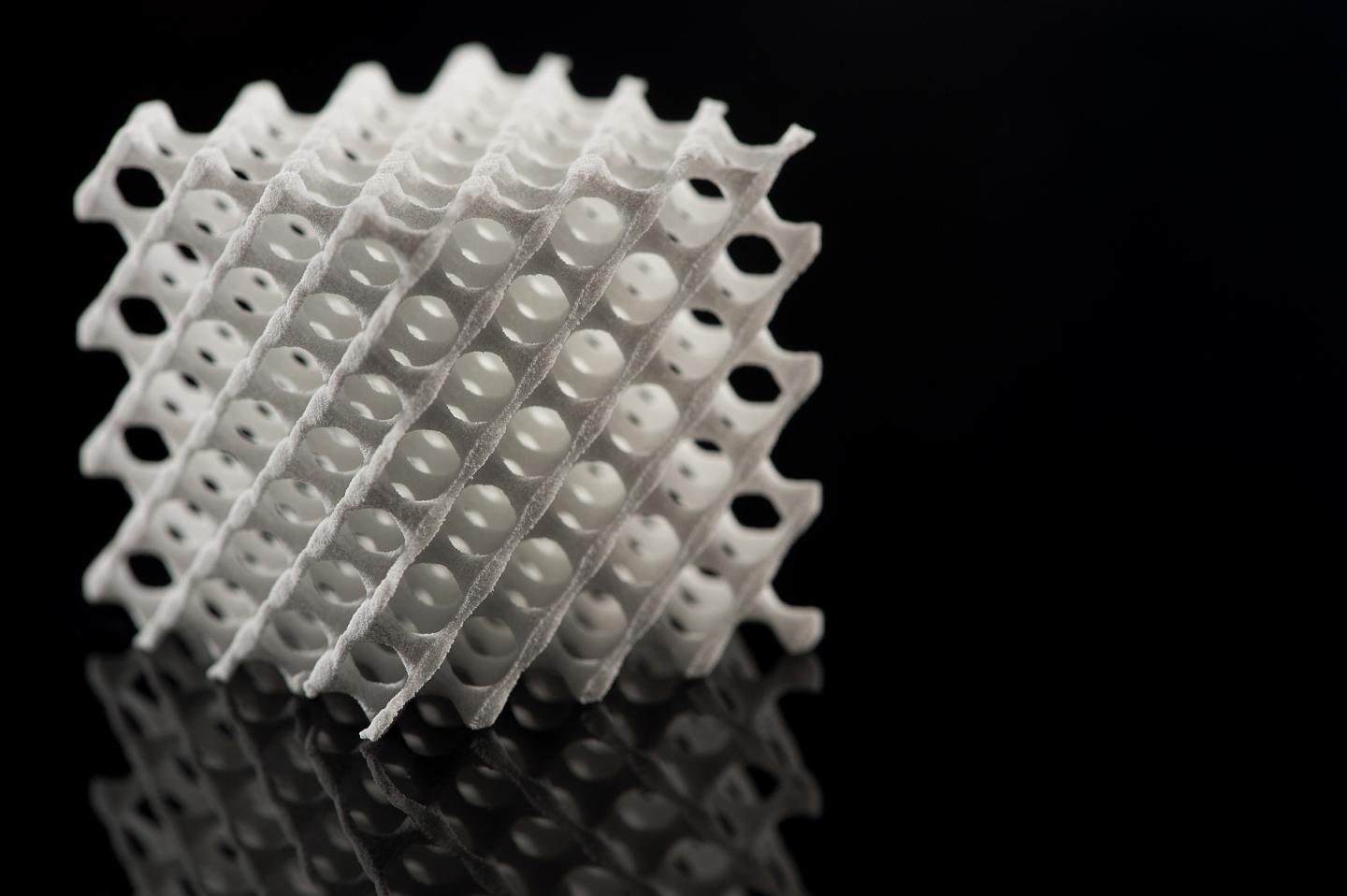

Credit: University of Nottingham

Engineers at The University of Nottingham are developing lightweight automotive components using new additive manufacturing processes to boost vehicle fuel efficiency, while cutting noise and CO2 emissions.

The components will be constructed using selective laser melting (SLM). SLM uses a 3-Dimensional Computer Aided Design model to digitally reproduce the object in a number of layers.

Each layer is sequentially recreated by melting sections of a bed of aluminium alloy powder using a laser beam. Layer by layer, the melted particles fuse and solidify to form novel structures that can be made up from complex lattices to provide a light-weight component.

SLM is a highly disruptive AM technology, helping to increase functionality and lower the number of separate components in production. This significant mass saving cuts component costs and increases overall vehicle efficiency.

The Functional Lattices for Automotive Components (FLAC) project aims to achieve significant weight reductions in mass (40-80 per cent) and optimised thermo-mechanical performance in new vehicle components.

The use of advanced lightweight materials in the project will serve to minimise wastage. Only the required material is incorporated into the built component, reducing costs, increasing the ability to manipulate the material to achieve the required performance and efficiency.

Environmental advantages include the inherent recyclability of the aluminium powder waste, reduced transportation and the elimination of special tooling and hazardous cutting fluids to produce the SLM parts.

The three-year FLAC project also will demonstrate the viability and cost analysis of the industrialisation of SLM, along with possible manufacturing routes and supply chain models.

FLAC project lead, Professor Chris Tuck, from the Additive Manufacturing and 3D Printing Research Group, said: "FLAC will benefit UK automotive companies, increasing their competitiveness by allowing them to adopt innovative routes for the design and manufacture of lightweight on-vehicle componentry, with shorter lead times and lower costs than are presently available.

The FLAC project, which has secured £368,286 from Innovate UK, will investigate components such as brake calipers, heat sinks for LED headlights and power train sub-systems.

The short-term market opportunity for these components – which will also deliver a decrease in CO2 emissions by 16.97g/km – lies in the luxury car and motorsport markets.

Professor Tuck said: "The automotive sector is one of the UK's leading export sectors by value, representing around 6.3 per cent of all UK exports. Successful delivery of FLAC's portfolio will enhance the R&D leadership in the key automotive technologies, and strengthen the UK automotive supply chain, resulting in increased revenues to the UK economy and government."

###

Media Contact

Emma Lowry

[email protected]

44-011-584-67156

@UoNPressOffice

http://www.nottingham.ac.uk

############

Story Source: Materials provided by Scienmag