Dr. Amir Asadi, an assistant professor in the Department of Engineering Technology and Industrial Distribution at Texas A&M University, is making groundbreaking strides in the field of composite materials. His research explores embedding patterned nanostructures composed of multiple materials into high-performance composites to achieve the desired multifunctionality without sacrificing any other properties. This could lead to advancements in various fields, including electronics, energy storage, transportation and consumer products.

Asadi’s work has significant implications, as it addresses the challenge of simultaneously enhancing two properties — multifunctionality and structural integrity — in composite materials, which consist of at least two materials with different properties. By incorporating patterned nanostructures, he aims to overcome the trade-off typically observed between these properties, eliminating the need to sacrifice one to improve the other in current manufacturing methods.

He explains, “Currently, manufacturing materials with concurrently maximized functionality and structural performance is considered paradoxical. For example, increasing electrical conductivity often reduces strength or vice versa; increasing strength usually decreases fracture toughness.”

However, Asadi draws inspiration from natural structures, such as the elephant trunk, which possesses seemingly incompatible properties and functionality.

“Natural structures with properties considered incompatible in today’s engineering already exist, such as an elephant trunk that is concurrently stiff and strong but also flexible and delicate to handle small vegetables while having communication and sensing functionalities, all arising from its muscular hydrostats architecture.”

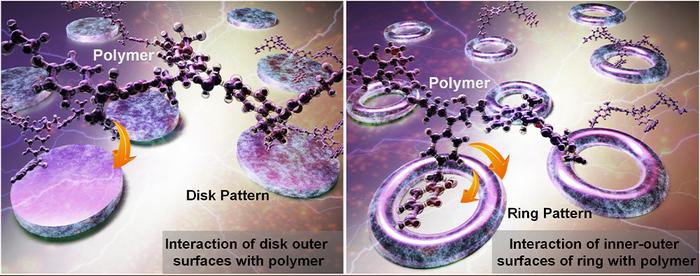

The research team used a unique method to adjust how much a material absorbs water or repels it, known as the amphiphilicity degree, in multiple nanomaterials. Using these materials, they created and combined specific patterns called ring and disk patterns, which govern the final properties of composite materials. To do this, they used a precise spray system with carbon dioxide (CO2) to deposit the patterns on the surface of carbon fibers. This allowed them to control the size of the droplets, the patterns on a microscopic scale and the materials’ interactions, ultimately achieving the desired properties. In this study, water droplets delivered the nanomaterials to the surface of carbon fibers using the spray system.

“We developed a new spray technique, referred to as supercritical-CO2 assisted atomization, which leverages the properties of supercritical CO2 and its high dissolution in water that can create several small droplets inside a suspension comprised of water and nanomaterials,” said Dr. Dorrin Jarrahbashi, co-author of the group’s journal article, “Multifunctionality Through Embedding Patterned Nanostructures in High-Performance Composites.”

“Unlike conventional approaches in which materials with desired intrinsic properties are integrated to add functionality, this research introduces the concept of integrating nanopatterns and shows that different patterns from the same material will lead to different properties in macroscale composites,” Asadi said. “If concurrent enhancement of functionality and structural properties is the goal, patterns can be combined and synergistically enhance all desired properties.”

There are various benefits of Asadi’s approach. It offers a practical, scalable, economically viable method for creating nanostructured materials and components with tunable properties. The use of diverse materials and precise control over architecture at multiple-length scales enhances the versatility and customization potential of the composites.

This pioneering work, funded by two National Science Foundation awards, has been published in Advanced Materials, one of the most prestigious journals in the field. Asadi acknowledges the invaluable contributions of his Ph.D. students Ozge Kaynan, Ehsan Hosseini, Farhad Zakertabrizi and Emile Motta De Castro, as well as the collaborative efforts of Dr. Lisa Perez and Jarrahbashi, in the success of this research.

As the research progresses, Asadi’s work will likely revolutionize the manufacturing of high-performance composites. With his dedication and expertise, Asadi is at the forefront of advancing the field of composite materials.

The potential impact of this research extends beyond the scientific community. “The research holds promise for impacting lives,” Asadi stated. “The introduced simple yet scalable technique will reduce the final cost of intricate and complex devices and broaden the manufacturing of nanostructured composites, contributing to the U.S. economy and labor market. This could result in improved devices, more efficient energy systems and innovative products that enhance everyday life.”

Credit: Courtesy of Dr. Amir Asadi

Dr. Amir Asadi, an assistant professor in the Department of Engineering Technology and Industrial Distribution at Texas A&M University, is making groundbreaking strides in the field of composite materials. His research explores embedding patterned nanostructures composed of multiple materials into high-performance composites to achieve the desired multifunctionality without sacrificing any other properties. This could lead to advancements in various fields, including electronics, energy storage, transportation and consumer products.

Asadi’s work has significant implications, as it addresses the challenge of simultaneously enhancing two properties — multifunctionality and structural integrity — in composite materials, which consist of at least two materials with different properties. By incorporating patterned nanostructures, he aims to overcome the trade-off typically observed between these properties, eliminating the need to sacrifice one to improve the other in current manufacturing methods.

He explains, “Currently, manufacturing materials with concurrently maximized functionality and structural performance is considered paradoxical. For example, increasing electrical conductivity often reduces strength or vice versa; increasing strength usually decreases fracture toughness.”

However, Asadi draws inspiration from natural structures, such as the elephant trunk, which possesses seemingly incompatible properties and functionality.

“Natural structures with properties considered incompatible in today’s engineering already exist, such as an elephant trunk that is concurrently stiff and strong but also flexible and delicate to handle small vegetables while having communication and sensing functionalities, all arising from its muscular hydrostats architecture.”

The research team used a unique method to adjust how much a material absorbs water or repels it, known as the amphiphilicity degree, in multiple nanomaterials. Using these materials, they created and combined specific patterns called ring and disk patterns, which govern the final properties of composite materials. To do this, they used a precise spray system with carbon dioxide (CO2) to deposit the patterns on the surface of carbon fibers. This allowed them to control the size of the droplets, the patterns on a microscopic scale and the materials’ interactions, ultimately achieving the desired properties. In this study, water droplets delivered the nanomaterials to the surface of carbon fibers using the spray system.

“We developed a new spray technique, referred to as supercritical-CO2 assisted atomization, which leverages the properties of supercritical CO2 and its high dissolution in water that can create several small droplets inside a suspension comprised of water and nanomaterials,” said Dr. Dorrin Jarrahbashi, co-author of the group’s journal article, “Multifunctionality Through Embedding Patterned Nanostructures in High-Performance Composites.”

“Unlike conventional approaches in which materials with desired intrinsic properties are integrated to add functionality, this research introduces the concept of integrating nanopatterns and shows that different patterns from the same material will lead to different properties in macroscale composites,” Asadi said. “If concurrent enhancement of functionality and structural properties is the goal, patterns can be combined and synergistically enhance all desired properties.”

There are various benefits of Asadi’s approach. It offers a practical, scalable, economically viable method for creating nanostructured materials and components with tunable properties. The use of diverse materials and precise control over architecture at multiple-length scales enhances the versatility and customization potential of the composites.

This pioneering work, funded by two National Science Foundation awards, has been published in Advanced Materials, one of the most prestigious journals in the field. Asadi acknowledges the invaluable contributions of his Ph.D. students Ozge Kaynan, Ehsan Hosseini, Farhad Zakertabrizi and Emile Motta De Castro, as well as the collaborative efforts of Dr. Lisa Perez and Jarrahbashi, in the success of this research.

As the research progresses, Asadi’s work will likely revolutionize the manufacturing of high-performance composites. With his dedication and expertise, Asadi is at the forefront of advancing the field of composite materials.

The potential impact of this research extends beyond the scientific community. “The research holds promise for impacting lives,” Asadi stated. “The introduced simple yet scalable technique will reduce the final cost of intricate and complex devices and broaden the manufacturing of nanostructured composites, contributing to the U.S. economy and labor market. This could result in improved devices, more efficient energy systems and innovative products that enhance everyday life.”

By Jesus A. Reina, Texas A&M Engineering

Journal

Advanced Materials

DOI

10.1002/adma.202300948

Article Title

Multifunctionality through Embedding Patterned Nanostructures in High-Performance Composites

Article Publication Date

24-May-2023