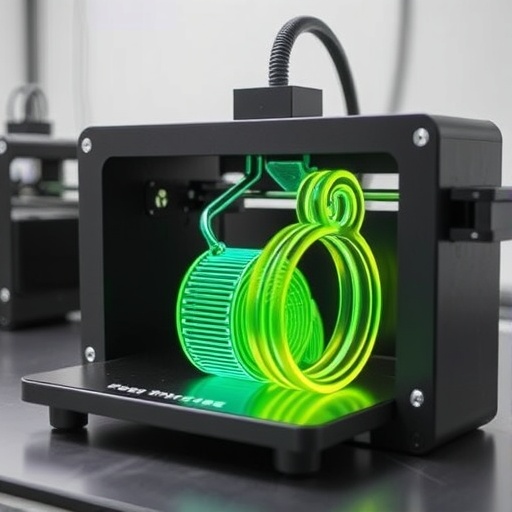

In the rapidly evolving landscape of additive manufacturing, or 3D printing, the quest for sustainable and environmentally friendly materials has become paramount. A groundbreaking advancement from the Helmholtz-Zentrum Hereon’s Institute of Functional Materials for Sustainability in Teltow brings new hope by developing a fully recyclable, wood-like ink derived from upcycled lignin. This innovation promises to revolutionize the 3D printing industry by aligning high-performance manufacturing with ecological responsibility. Unlike traditional methods that rely heavily on fossil-based polymers—materials notorious for their environmental persistence and inability to be recycled—this novel approach leverages lignin, an abundant industrial waste product, offering a sustainable alternative that does not compromise on functionality.

Additive manufacturing techniques have redefined the production of complex geometries by building objects layer by layer, directly from digital models. Among these techniques, direct ink writing (DIW) stands out due to its room-temperature operation and versatility, printing various formulations of inks. Historically, these inks were predominantly fossil-derived and chemically crosslinked or heat-treated, restricting their recyclability and life cycle. The innovation by Dr. Maria Balk and her team transcends these limitations by formulating a water-based lignin ink that maintains fluidity under pressure for smooth extrusion, and rapid solidification post-deposition, without requiring any thermal or chemical post-processing. This marks a significant stride toward sustainable additive manufacturing processes.

Lignin, a primary component in the cell walls of plants and a byproduct of the paper industry, has typically been considered a low-value waste stream, often discarded or incinerated. Its molecular complexity and high thermal stability have historically complicated its incorporation into 3D printing inks suitable for DIW. The Hereon team, however, devised a strategy to convert this underutilized biomass into a major component—comprising approximately 70% of the printing ink—thereby not only diverting waste but also harnessing a renewable resource to fabricate high-quality printed objects. The resulting ink exhibits viscoelastic properties ideal for DIW, enabling precise extrusion and shape retention, which are critical for producing intricate and sturdy 3D objects.

What sets this lignin-based ink apart is its unprecedented recyclability. Once objects are printed and used, they can be rehydrated, effectively dissolving or softening the material to revert it back into ink form without loss of structural or mechanical integrity. This cycle can be repeated multiple times, maintaining consistent performance with each reuse. Such a capability is rare within the realm of additive manufacturing and could disrupt conventional production-consumption-disposal paradigms by enabling a truly circular manufacturing cycle. This innovation also dramatically reduces the generation of persistent plastic waste and diminishes the carbon footprint associated with material synthesis and disposal.

The technical mastery behind the ink’s performance lies in its aqueous formulation and the molecular interactions between lignin and the solvent medium. The water-based system ensures low energy consumption during printing—eliminating the need for high-temperature curing or crosslinking agents—thereby aligning with principles of green chemistry. More importantly, the ink’s rheological properties strike a balance between fluidity and structural integrity, crucial to maintaining print fidelity. After extrusion, the ink rapidly recovers its strength, allowing layer-by-layer building without deformation, a challenge that often plagues alternative recyclable inks that lose shape retention post-printing.

From a materials science perspective, this approach opens avenues for fine-tuning polymer blend characteristics directly from biomass-derived components. Lignin’s aromatic and hydrophobic nature imparts unique mechanical strengths and chemical resistance to the printed parts, making them suitable for diverse applications, ranging from automotive components to medical device prototypes. The absence of permanent chemical bonds or thermal crosslinking in the printed objects ensures that these advantageous properties do not come at the expense of recyclability, setting a new benchmark in 3D printing materials research.

This development aligns with broader sustainability goals within manufacturing sectors aiming to reduce environmental impact while maintaining or improving product quality. By valorizing industrial waste streams and integrating them into production technologies, the Hereon study exemplifies circular economy principles—from resource recovery to end-of-life material reintegration. Given the urgency to mitigate climate change effects and reduce reliance on fossil feedstocks, the deployment of such lignin-based inks could support industries in transitioning toward lower carbon footprints and waste minimization.

The interdisciplinary nature of this research, bridging chemistry, materials engineering, and sustainability science, underscores the future of manufacturing innovation. The Hereon team’s usage of advanced characterization techniques and experimental studies to optimize ink formulations highlights the synergy between fundamental material understanding and practical application. Future work aims at scaling the process and exploring its applicability in real-world scenarios, especially where low-energy processing and recyclability are critical, such as in consumer electronics, packaging, and custom medical implants.

Furthermore, this technology could catalyze new business models centering on material reuse and closed-loop supply chains. Companies adopting fully recyclable inks will be better positioned to meet increasingly stringent environmental regulations and consumer demands for sustainable products. By fostering innovation at the material level, this approach not only enhances device performance and manufacturing efficiency but also addresses systemic issues of waste accumulation and resource depletion currently faced by the plastics and polymer industries.

The implications of this research extend beyond additive manufacturing. Lignin’s availability and chemical diversity make it a versatile platform for future sustainable materials across other sectors, including coatings, adhesives, and composites. Developing scalable and economically viable pathways for lignin valorization could transform biomass-derived residues into valuable feedstocks, incentivizing broader adoption of bio-based manufacturing processes that cooperate with ecological systems rather than degrade them.

Helmholtz-Zentrum Hereon’s vision of creating technologies that preserve a livable planet is vividly realized through this cutting-edge work on recyclable lignin inks. Their integrated approach combines experimental validation, computational modeling, and real-world application testing, ensuring that innovations can swiftly transition from laboratory discovery to impactful industrial solutions. As the 3D printing community grapples with its environmental footprint, this advancement offers a practical and scalable pathway toward more sustainable manufacturing futures.

In conclusion, the development of a room-temperature, aqueous-based lignin-derived ink that is not only effective for direct ink writing but also fully recyclable represents a milestone in additive manufacturing technology. It breaks new ground in sustainability by challenging the status quo of non-recyclable polymer-based inks, offering instead a high-performance, circular-printing material derived from abundant waste resources. This innovation holds promise not only for reducing environmental impact but also for inspiring a broader transformation in how materials and manufacturing processes are conceived, designed, and implemented worldwide.

Subject of Research: Not applicable

Article Title: Room-Temperature, Aqueous-Based 3D Printing of Fully Recyclable Wood-like Inks from Upcycled Lignin

News Publication Date: 11-Feb-2026

Web References: DOI: 10.1021/acssuschemeng.5c07974

Image Credits: Hereon/Steffen Niemann

Keywords

Applied sciences and engineering

Tags: direct ink writing advancementseco-friendly 3D printing technologiesenvironmental impact of 3D printingfunctional materials for eco-conscious manufacturingHelmholtz-Zentrum Hereon researchhigh-performance recyclable materialsinnovative materials in 3D printinglignin-based inks for sustainabilityovercoming limitations of fossil-derived inksrecyclable 3D printing inksustainable additive manufacturing materialsupcycled lignin for ink production