In the relentless pursuit of higher energy densities and longer-lasting lithium-ion batteries, silicon anodes have long been heralded as a transformative advance. Silicon’s allure lies in its exceptionally high theoretical capacity, capable of storing nearly ten times the lithium ions compared to conventional graphite anodes. However, the path to commercial viability has been littered with challenges, chiefly the mechanical degradation of the solid electrolyte interphase (SEI) layer triggered by silicon’s volumetric expansion during lithiation and delithiation cycles. This fundamental obstacle has limited silicon’s potential in practical applications, impeding its cycle life and calendar life alike. Yet, a recent study published in Nature Energy by Zhang et al. presents a groundbreaking mechanistic understanding that promises to reshape our approach to silicon anodes, potentially extending battery lifespans far beyond current standards.

At the heart of silicon anode degradation is the SEI, a nanoscale film formed at the electrode-electrolyte interface, designed to facilitate lithium-ion transport while isolating the electrolyte from direct contact with the electrode. Conventional solid electrolyte interphases, especially those formed on micro-silicon (µ-Si), exhibit strong adhesion to the silicon surface. While this robust bonding initially appears beneficial, it ironically becomes a double-edged sword. Volumetric fluctuations inherent to silicon during cycling induce mechanical stress, causing these SEIs to crack and fragment irreversibly. These fractures expose fresh silicon to the electrolyte, prompting continuous SEI reformation and a cascading depletion of active lithium and electrolyte components, which culminate in rapid performance decline.

To circumvent the cracking dilemma, researchers pivoted towards nano-silicon, whose smaller particle size theoretically accommodates volumetric strain more effectively and reduces internal stresses. Numerous studies have confirmed that nano-silicon anodes manifest improved cycling durability compared to their micro-sized counterparts. However, nano-silicon’s promise is not without its pitfalls. Its increased surface area exacerbates SEI instability through heightened dissolution rates, exacerbating capacity fade particularly during calendar ageing—the gradual performance decay experienced even when the battery is not subjected to cycling stresses. Moreover, the economic feasibility of nano-silicon remains a significant barrier due to complex manufacturing and cost constraints.

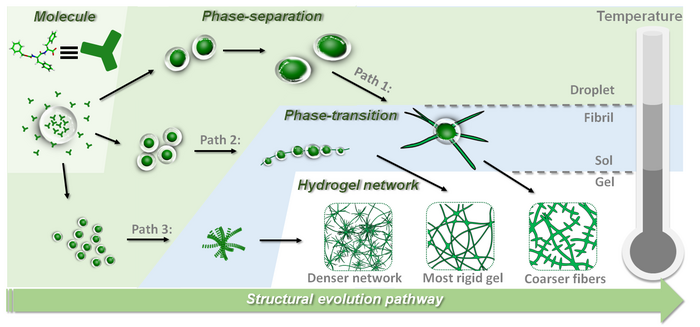

Enter the pivotal insights from Zhang et al., whose team employed potentiostatic aging tests to dissect the intricate interplay between calendar ageing and cycle ageing in silicon anodes. Their detailed mechanistic study revealed that both ageing modes are fundamentally governed by two intertwined phenomena: SEI cracking and SEI dissolution. Crucially, the relative dominance of either cracking or dissolution varies depending on the material architecture and SEI chemistry, ultimately shaping the anode’s lifespan.

When the system’s degradation dynamics are not overwhelmed by SEI dissolution, the team found a positive correlation between calendar life and cycle life performance. This discovery implies that materials engineering targeted at reducing SEI cracking should simultaneously enhance both calendar and cycling durability. Specifically, the study highlighted the exceptional role of lithium fluoride (LiF)-rich SEIs formed on µ-Si anodes, a composition that minimizes mechanical failure within the SEI and impedes dissolution processes. By engineering an SEI rich in LiF, researchers can drastically suppress cracking, stabilizing the interface sufficiently to extend not only the cycle life but also the calendar life of silicon anodes.

Based on this framework, Zhang et al. undertook a comprehensive screening of various electrolytes, SEIs, and electrode formulations, systematically exploring how each variable influences degradation pathways. This exhaustive approach allowed the team to validate their theoretical predictions using full-cell storage experiments, lending unprecedented clarity to the mechanistic forces underpinning silicon anode ageing.

One of the most profound outcomes from their study is the elucidation of why µ-Si, despite its historical cycling limitations, can outperform nano-silicon in calendar life when paired with a LiF-rich SEI. LiF’s chemical and mechanical robustness ensures the integrity of the SEI through repeated expansion-contraction cycles and over extended periods of rest, preventing electrolyte permeation and mitigating capacity fade. In stark contrast, nano-silicon, while benefiting from reduced mechanical stress, suffers from the accelerated dissolution of its SEI due to its larger surface-to-volume ratio, a process that severely curtails its calendar life.

Armed with these insights, the research provides a clear directive for extending silicon anode longevity: focus on the formation of stable, LiF-rich SEIs and carefully manage electrolyte-electrode interface contact to prevent SEI dissolution. For nano-silicon architectures, this means minimizing electrolyte exposure, potentially through protective coatings or solid electrolyte architectures, to curb dissolution-driven ageing.

Beyond mere theoretical exploration, the study’s implications are profound for battery engineering and commercialization. By identifying the chemical and mechanical fingerprints of long-lasting SEIs, battery developers now hold a strategic blueprint for electrolyte formulation and electrode design that balances mechanical resilience with chemical stability. It opens the door to tailor-made electrolytes capable of fostering LiF formation, alongside nano- or micro-structured silicon architectures optimized for durability, cost-effectiveness, and manufacturability.

Moreover, the methodical approach to disentangling calendar and cycle ageing pathways via potentiostatic aging tests introduces a novel experimental paradigm for future battery research. This technique offers a robust platform for systematically evaluating the longevity potential of emerging electrode materials and SEI chemistries under practical storage and cycling conditions.

The convergence of mechanical and chemical stabilization strategies elucidated by this study signals a critical step toward truly viable silicon anodes, which many in the field have long sought yet struggled to achieve. It reconciles previously conflicting paths by acknowledging that while nano-silicon offers certain mechanical advantages, these alone are insufficient without chemical resilience of the interphase. Meanwhile, micro-silicon, enhanced with the right SEI chemistry, can overcome its mechanical shortcomings to deliver exceptional calendar and cycling lifetimes.

In the broader context of lithium-ion battery evolution, these findings accelerate the timeline for silicon adoption in commercial cells, promising significant boosts in energy density without the prohibitive trade-offs in lifespan and durability that have historically hampered silicon-based anodes. They also underscore the paramount importance of interphase chemistry, often overshadowed by pure material design, spotlighting the SEI not merely as a passive skin but an actively engineered component dictating cell longevity.

Looking ahead, this pivotal research invites further exploration into scalable electrolyte additives or formulations that promote robust LiF-layer formation, alongside advanced electrode architectures engineered to modulate electrolyte contact and reduce dissolution risks. It also encourages integration with next-generation cell designs leveraging solid-state or hybrid electrolytes, which may synergistically amplify SEI stability and overall cell robustness.

In essence, Zhang et al.’s work crystallizes a clear mechanistic roadmap from SEI design to silicon anode endurance, transforming a persistent bottleneck in battery technology into an actionable frontier. By harmonizing mechanical integrity with chemical stability at the interphase, this research sets a new benchmark for silicon anode development, catalyzing progress toward the long-sought goal of high-capacity, long-life lithium-ion batteries that could revolutionize everything from portable electronics to electric vehicles.

As the battery industry continues to evolve rapidly, breakthroughs such as this elevate silicon anodes from experimental curiosities to promising candidates for widespread adoption. The dual challenge of calendar and cycle ageing, once a vexing barrier, is now demystified and made tractable through strategic interphase engineering—a leap forward that holds the potential to redefine energy storage paradigms for decades to come.

Subject of Research: Mechanistic analysis of solid electrolyte interphase (SEI) formation, ageing, and stability on silicon anodes in lithium-ion batteries.

Article Title: Mechanistic understanding of interphase-driven ageing in silicon anodes.

Article References:

Zhang, W., Zhang, N., Wang, Z. et al. Mechanistic understanding of interphase-driven ageing in silicon anodes. Nat Energy (2026). https://doi.org/10.1038/s41560-026-01967-1

Image Credits: AI Generated

DOI: https://doi.org/10.1038/s41560-026-01967-1

Keywords: silicon anodes, solid electrolyte interphase (SEI), lithium fluoride (LiF), battery ageing, calendar life, cycle life, silicon volume expansion, electrolyte formulation, potentiostatic ageing tests, lithium-ion batteries

Tags: challenges in battery lifespan extensioncommercial viability of silicon anodescycle life of lithium-ion batterieshigh energy density battery technologylithium-ion transport mechanismsmechanical degradation in battery materialsnanoscale films in electrochemistryNature Energy study on siliconrecent advancements in battery researchsilicon anodes in lithium-ion batteriessolid electrolyte interphase degradationvolumetric expansion in silicon