In recent decades, advancements in 3D printing technology have permeated various sectors, with healthcare witnessing a remarkable transformation. Among these innovations, 3D-printed wrist orthoses are emerging as a competitive alternative to traditional low-temperature thermoplastic orthoses. Recent research by von Haller, Couchman, and Honigmann examines the economic implications of manufacturing these two orthotic systems. Their findings contribute valuable insights into patient care practices, cost efficiencies, and future directions for orthotic design.

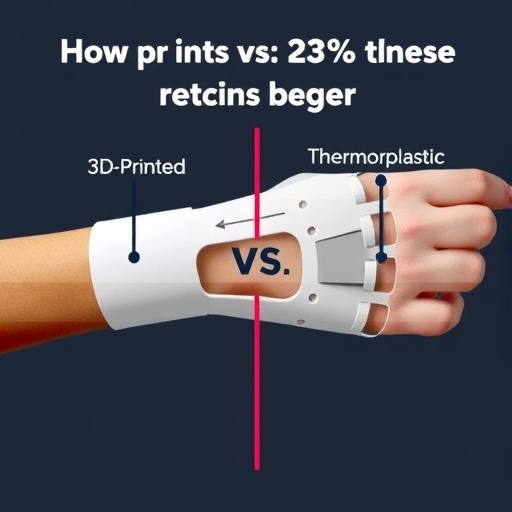

At the forefront of this study is the exploration of production methods used to create wrist orthoses. Traditional low-temperature thermoplastic orthoses require manual shaping, often leading to longer fabrication times and potentially higher labor costs. In contrast, 3D printing allows for a streamlined manufacturing process, enabling faster production times without compromising design intricacies. This variance raises critical questions about the overall cost-effectiveness of these two approaches, particularly in a healthcare landscape increasingly focused on economic viability.

One of the most compelling aspects of 3D printing technology is its ability to tailor orthoses to individual patient anatomies. The customization capabilities afforded by 3D printing not only enhance patient comfort but also improve the efficacy of orthotic devices. Personalized fits reduce the risk of skin irritation and discomfort that can occur with standard-sized orthoses. By examining how economic factors weigh against clinical advantages, the researchers underscore the critical balance between patient-centered design and cost management.

Moreover, the study assesses various economic indicators associated with both manufacturing processes. This includes direct costs such as raw materials and technology investments, as well as indirect costs like time spent by healthcare professionals on fitting and adjustments. The comprehensive evaluation provides a comparative framework to gauge which method could ultimately deliver the most economic benefit while serving patient needs adequately.

The research also highlights the environmental aspect of 3D-printed orthoses. Sustainable production practices are becoming crucial in modern manufacturing. The materials used in 3D printing can often be more sustainable compared to traditional materials. As the healthcare sector aims to minimize its environmental footprint, the study discusses the implications of material selection on ecological sustainability.

The findings presented by von Haller et al. also invoke a larger conversation about technological innovations in healthcare. The potential for integrating artificial intelligence and machine learning into the design and manufacturing of orthoses could further enhance efficiencies. As 3D printing continues to evolve, the interplay between these technologies could unlock even greater advancements in orthotic design and production.

Furthermore, the analysis outlines the training necessary for healthcare professionals to effectively adopt these new technologies. Transitioning from traditional methods to 3D printing does not merely require updated machinery; it necessitates a paradigm shift in how healthcare services prepare and equip staff to engage with this growing field. Professional development and training programs will become integral in ensuring a smooth transition and sustainable adoption of 3D printing in practice.

The implications of this research reach beyond orthoses, highlighting possibilities for other areas within prosthetics and rehabilitation. As the healthcare industry continues to explore the benefits and limitations of additive manufacturing, there is a growing interest in how these methods can be adapted for various applications. By setting a precedent in wrist orthoses, this study could inspire advancements across a wide spectrum of medical devices.

Ultimately, the study serves as a pivotal contribution to ongoing discourse on the economic evaluation of 3D printing in healthcare. As the demand for innovative and cost-effective solutions intensifies, the potential for 3D-printed orthotic devices to reshape patient care models becomes increasingly apparent. The integration of these new technologies promises not only to enhance clinical outcomes but also to ensure a more efficient allocation of resources within healthcare systems.

As healthcare professionals are continually challenged to do more with less, the insights gleaned from this study provide a much-needed perspective. Moving forward, healthcare systems and policymakers can leverage these findings to inform decisions about resource allocation, technology investments, and ultimately, the quality of patient care delivered.

In conclusion, the research conducted by von Haller, Couchman, and Honigmann illuminates a critical intersection of technology and healthcare economics. Their exploration into the manufacturing of wrist orthoses via 3D printing versus traditional methods underscores the power of innovation in forging pathways toward improved efficiencies and outcomes. The findings will likely resonate throughout the healthcare community, propelling discussions about the future landscape of healthcare technology and its lasting impacts on patient care protocols.

Subject of Research: Economic evaluation of 3D-printed wrist orthoses versus low-temperature thermoplastic wrist orthoses.

Article Title: Economic evaluation of the manufacturing of 3D-printed wrist orthoses vs low temperature thermoplastic wrist orthoses.

Article References: von Haller, M., Couchman, L. & Honigmann, P. Economic evaluation of the manufacturing of 3D-printed wrist orthoses vs low temperature thermoplastic wrist orthoses. 3D Print Med 11, 35 (2025). https://doi.org/10.1186/s41205-025-00287-6

Image Credits: AI Generated

DOI: https://doi.org/10.1186/s41205-025-00287-6

Keywords: 3D printing, wrist orthoses, economic evaluation, healthcare technology, customization, sustainability.

Tags: 3D-printed wrist orthosescost-effectiveness of 3D printingcustomization in orthotic treatmenteconomic implications of orthotic designfuture of orthotic technologyhealthcare advancements in orthoticslabor costs in orthotic fabricationmanufacturing methods in orthoticspatient care and orthotic devicesproduction efficiency in healthcaretailored orthotic solutionsthermoplastic orthoses cost comparison