Researchers at the forefront of automotive engineering are unveiling fascinating insights into the dynamics of combustion engines in their latest study. This groundbreaking research focuses on the intricate patterns of swirl motion that characterize in-cylinder flow in compression ignition (CI) engines under firing conditions. Understanding these patterns is crucial for optimizing engine efficiency and emissions control. The team, led by scientists Aljarf, Singh, and Baiju, employs advanced techniques such as Particle Image Velocimetry (PIV) and Proper Orthogonal Decomposition (POD) to navigate the complexities of in-cylinder airflow.

The significance of this study cannot be understated. The swirl motion and turbulence of the air-fuel mixture inside the combustion chamber directly influence the mixing process, combustion efficiency, and ultimately, engine performance. With increasing environmental regulations and the global push for cleaner technologies, enhancing the efficiency of diesel engines has become a paramount goal. This research aims to bridge the gap in understanding how preinjection strategies can modify flow patterns, ultimately affecting combustion processes.

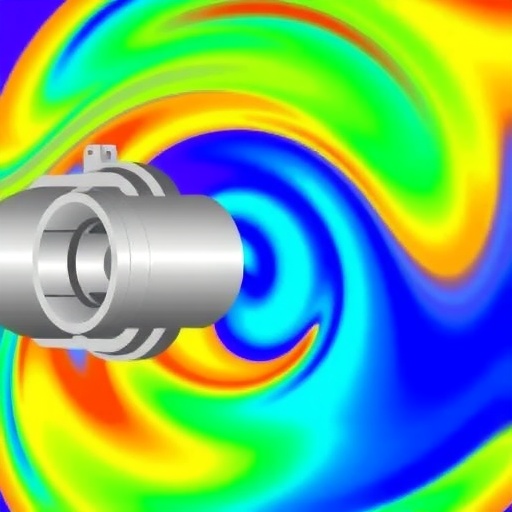

The experimental investigation conducted by the team primarily utilized PIV, a powerful optical method that allows for the visualization and measurement of velocity fields in fluid flows. By illuminating a thin plane of the fluid with laser light and capturing the movement of tracer particles suspended in the flow, PIV provides a detailed view of the flow structures. The resulting data allowed researchers to assess how preinjection impacts the swirl levels and turbulent characteristics within the combustion chamber.

Proper Orthogonal Decomposition, on the other hand, is a sophisticated mathematical technique that decomposes complex flow fields into a set of orthogonal modes. By identifying dominant patterns that emerge within the flow, POD facilitates a clearer understanding of how different parameters, such as injection timing and pressure, influence swirl motion. Together, these techniques afford the research team a robust framework to analyze the interactions of various turbulent flow structures effectively.

Central to the study is the exploration of preinjection—an innovative strategy that involves injecting a small amount of fuel into the combustion chamber before the main injection event. This technique seeks to enhance the air-fuel mixture’s homogeneity, thus promoting better combustion efficiency and lower emissions. The researchers meticulously varied preinjection timings and volumes during their experiments to identify optimal conditions that would induce beneficial swirl patterns.

The preliminary findings indicate a significant correlation between preinjection conditions and the development of swirl motion. Specifically, optimizing these parameters could lead to an increase in the average swirl number, enhancing the agitation of the air-fuel mixture prior to ignition. Additionally, the results suggest that strategically timed preinjections could produce more favorable turbulence characteristics, significantly affecting combustion stability.

Moreover, the team’s research highlights the role of combustion chamber geometry in swirl formation. Variations in the design of combustion chambers can lead to differing flow dynamics, which in turn affects how effectively fuel mixes with air. This is an essential consideration for engineers looking to design next-generation CI engines capable of meeting stringent emissions targets while maintaining performance.

The investigation also delves into the implications of swirl motion on engine combustion phases. Understanding how swirl influences ignition delay and combustion duration provides critical insights into optimizing fuel consumption. The findings indicate that increased swirl can lead to quicker ignition and more complete combustion, which would be crucial for improving thermal efficiency and reducing engine knock.

As environmental concerns escalate globally, the prescriptions drawn from this study become increasingly relevant. The automotive industry is under pressure not only to enhance performance but also to minimize the carbon footprint of its vehicles. By exploring advanced combustion techniques, such as those discussed, the industry takes a significant step toward creating engines that are both powerful and environmentally friendly.

This research opens up avenues for future investigations that could focus on integrating real-time feedback mechanisms within CI engines to adapt their operation dynamically based on in-cylinder flow characteristics. Such advancements could make it possible to optimize engine performance in real-time, further pushing the boundaries of what is achievable with current technology.

As the automotive sector continues to evolve toward hybrid and electric vehicles, studies like this will remain pivotal. They serve as a reminder that traditional combustion engines still hold potential for innovation and improvement. By leveraging advanced experimental techniques, researchers can illuminate pathways to enhance existing technologies, helping pave the way for a cleaner future.

Ultimately, the work of Aljarf, Singh, Baiju, and their team not only elucidates the complexities of in-cylinder flow dynamics but also underscores the potential for revolutionary changes in CI engine design and optimization. Their comprehensive approach combining advanced measurement techniques with innovative experimental setups illustrates a new frontier in the realm of automotive research.

In conclusion, the exploration of swirl motion and its effects on in-cylinder flow demonstrates the significant role that experimental investigations play in modern engineering. By illuminating the connections between fuel injection strategies and engine performance, researchers are not just contributing to academic knowledge but are also directly influencing the development of sustainable automotive technologies.

Subject of Research: Swirl motion in in-cylinder flow of CI engines under firing conditions.

Article Title: Experimental investigation of swirl motion of in-cylinder flow in CI engine under firing condition due to preinjection using PIV and POD techniques.

Article References:

Aljarf, S., Singh, H., Baiju, V. et al. Experimental investigation of swirl motion of in-cylinder flow in CI engine under firing condition due to preinjection using PIV and POD techniques.

Automot. Engine Technol. 8, 73–93 (2023). https://doi.org/10.1007/s41104-023-00126-y

Image Credits: AI Generated

DOI: 10.1007/s41104-023-00126-y

Keywords: CI engine, swirl motion, preinjection, PIV, POD, combustion efficiency, automotive research.

Tags: advanced automotive technologiesautomotive engineering researchcombustion chamber turbulencecombustion efficiency optimizationdiesel engine emissions controlenvironmental impact of diesel enginesfluid flow visualization methodsin-cylinder airflow analysisParticle Image Velocimetry techniquespreinjection strategies in CI enginesProper Orthogonal Decomposition applicationsswirl dynamics in diesel engines