In the rapidly evolving landscape of medical technology, 3D printing has emerged as a revolutionary tool, particularly within the realm of surgical applications. The versatility of additive manufacturing allows for the creation of highly customized medical devices tailored specifically to individual patients. Among these innovations, surgical cutting guides stand out, aiding surgeons during intricate procedures by improving precision and efficiency. However, the introduction of these devices into clinical environments necessitates rigorous assessment of their performance, particularly regarding dimensional accuracy, especially after undergoing sterilization processes.

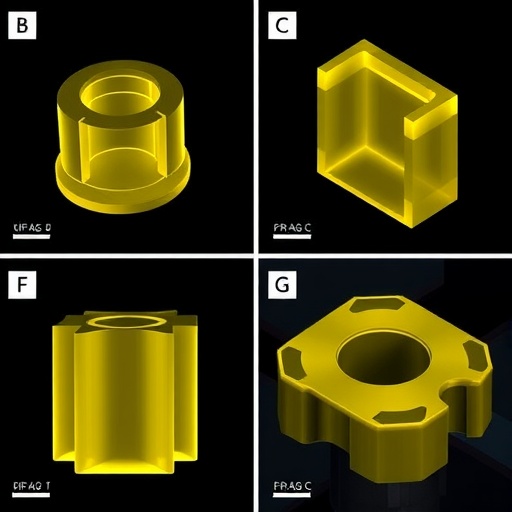

The recent study conducted by Popescu et al. sheds light on the critical aspect of dimensional accuracy of 3D-printed surgical cutting guides post-sterilization. This aspect is pivotal when considering the reliability and effectiveness of these guides in actual surgical settings. The evaluation of a set of ten different materials through a series of tests revealed vital insights about the potential impact of the sterilization process on the precision of these surgical aids. Such insights can guide clinicians in selecting the most appropriate materials and techniques for specific surgical applications.

The research highlights an essential gap in existing literature—while 3D printing technology has been widely adopted, comprehensive assessments of the printed materials under clinical sterilization processes have been minimal. This study addresses that gap, presenting valuable data that could inform future best practices in clinical settings, thus promoting safer and more effective surgical procedures. Each of the ten materials was subjected to standard hospital sterilization techniques, and their dimensional changes were meticulously recorded and analyzed.

After undergoing sterilization, each material exhibited varying degrees of shrinkage and deformation, which could potentially compromise the accuracy of the cutting guides. Such discrepancies raise concerns about the overall upkeep of material stability during sterilization cycles, underscoring the necessity for continuous improvement in both the 3D printing processes and the materials used. The study’s findings indicate that while some materials fared better than others, the implications for surgical outcomes are profound and warrant further investigation.

The research involves a comparison of dimensional measurements taken before and after sterilization, utilizing precise equipment and methodologies to ensure the reliability of the results. By assessing parameters such as length, width, and thickness, the study carefully analyzed how each material’s properties changed through the sterilization processes. The implications of these findings extend beyond mere material selection; they emphasize the importance of regulatory standards for 3D-printed medical devices in ensuring patient safety.

Another significant aspect of this study lies in its methodology. By employing a rigorous comparative evaluation across multiple materials, the authors were able to identify not only which materials maintained their dimensional accuracy but also the mechanisms behind the observed changes. Such an understanding is crucial for advancing the field of additive manufacturing in medicine, as it encapsulates the complex relationship between material science and surgical efficacy.

Moreover, the findings present an opportunity for manufacturers to improve the formulation of 3D printing materials, making them more resilient to the rigors of clinical sterilization. In an industry where precise dimensions are paramount, even minor inaccuracies can lead to significant complications during surgical interventions. Thus, the drive for innovation in material science is essential for the future of 3D-printed medical devices.

As the demand for personalized medical solutions continues to rise, the implications of this research resonate not only within surgical fields but across healthcare disciplines at large. It sets a precedent for the necessity of data-driven decision-making when integrating advanced technologies, such as 3D printing, into clinical workflows. With continuous advancements, the potential for enhancing surgical outcomes and patient safety through tailored solutions is remarkably promising.

In conclusion, the comparative evaluation presented by Popescu et al. offers critical insights into the performance of 3D-printed surgical cutting guides post-sterilization. As the medical community embraces these innovative solutions, ongoing research and evaluation will be key to ensuring their efficacy and reliability. The outcomes of this study serve as an essential foundation for future investigations and developments in the field of medical 3D printing—an area with boundless potential.

The journey towards optimizing surgical technologies is not just a technical endeavor; it involves collaboration among healthcare professionals, engineers, and researchers to create safer, more effective medical solutions. As technology continues to advance, such studies play a crucial role in bridging the gap between innovation and practical, clinical application.

With the imperative of safety and precision at the forefront, the findings from this research are not only timely but also critical for guiding future directions in 3D printing technologies within the medical field. As further advancements in materials and processes are made, the prospects for achieving unmatched quality in surgical care through additive manufacturing increasingly become a reality.

Subject of Research: Dimensional accuracy of 3D printed surgical cutting guides after hospital sterilization.

Article Title: Dimensional accuracy of 3D-printed surgical cutting guides after hospital sterilization: a comparative evaluation of ten MEX materials.

Article References:

Popescu, D., Iacob, M.C. & Marinescu, R. Dimensional accuracy of 3D-printed surgical cutting guides after hospital sterilization: a comparative evaluation of ten MEX materials. 3D Print Med 11, 44 (2025). https://doi.org/10.1186/s41205-025-00291-w

Image Credits: AI Generated

DOI: https://doi.org/10.1186/s41205-025-00291-w

Keywords: 3D printing, surgical cutting guides, dimensional accuracy, sterilization, MEX materials, medical technology.

Tags: 3D printing in surgeryadditive manufacturing in healthcareadvancements in medical technologyclinical assessment of 3D-printed guidescustomized medical devicesdimensional accuracy in surgical aidsevaluating sterilization processesimpact of materials on surgical precisionmaterial comparison in medical devicesprecision of surgical cutting guidesreliability of surgical toolssterilization effects on 3D-printed materials