In the rapidly evolving landscape of advanced manufacturing, the pursuit of materials that offer superior mechanical performance and resilience under extreme conditions has become paramount. Recent developments have spotlighted zirconium diboride (ZrB2), a ceramic material lauded for its exceptional hardness, high melting point, and excellent thermal stability. Despite its promise, the fabrication of ZrB2 components with tailored microstructures and enhanced properties has posed significant challenges. Addressing these challenges, researchers have now unveiled a groundbreaking study that harnesses the synergy of carbon fiber reinforcement and optimized sintering temperatures, coupled with innovative material extrusion additive manufacturing techniques, to elevate the functional capabilities of zirconium diboride.

ZrB2’s intrinsic characteristics, such as its ultra-high hardness and impressive resistance to thermal shock, make it an ideal candidate for applications spanning aerospace, nuclear reactors, and cutting tools. However, its inherent brittleness and difficulty in processing have historically limited its widespread use. Traditional manufacturing methods often lead to materials plagued by microstructural inconsistencies, poor densification, and suboptimal mechanical properties. To circumvent these limitations, the research team employed a material extrusion additive manufacturing approach, which offers unprecedented control over component geometry and porosity, thereby enabling the fine-tuning of microstructure at a microscopic scale.

A pivotal innovation in this study lies in the reinforcement of zirconium diboride with carbon fibers. Carbon fibers are renowned for their extraordinary tensile strength, lightweight nature, and thermal stability, properties that synergistically complement the characteristics of ZrB2. The integration of carbon fibers within the ceramic matrix aims to enhance load-bearing capacity, mitigate crack propagation, and improve thermal shock resistance. By embedding these fibers uniformly within zirconium diboride powders prior to extrusion, the researchers effectively engineered a composite material whose microstructural arrangement promotes superior mechanical integrity without compromising thermal performance.

The researchers meticulously analyzed the influence of sintering temperature—a critical step that determines grain growth, densification, and phase stability—on the resultant properties of the carbon fiber-reinforced zirconium diboride composites. Sintering at elevated temperatures generally enhances density but can also induce grain coarsening, leading to reduced strength. Conversely, lower sintering temperatures may preserve finer microstructures but at the expense of incomplete densification. Through a systematic exploration of temperature regimes, the study identified an optimal balance that maximizes mechanical robustness while maintaining microstructural refinement. This delicate equilibrium underscores the importance of precise thermal management in the fabrication process.

Mechanical testing unveiled remarkable improvements in critical parameters such as flexural strength, fracture toughness, and hardness in the carbon fiber-reinforced specimens compared to their unreinforced counterparts. The inclusion of carbon fibers not only acted as physical barriers to crack initiation but also facilitated stress transfer across the ceramic matrix, effectively distributing loads and delaying failure. These enhancements position the composites as viable materials for applications subject to intense mechanical stresses and rapid thermal fluctuations, thereby broadening the utility of zirconium diboride beyond conventional domains.

Thermal shock resistance, an essential property for materials exposed to sudden temperature changes, was substantially elevated in the reinforced composites. The carbon fibers contributed to the accommodation of thermal strains by bridging microcracks and absorbing cyclic stresses, mechanisms that collectively reduced degradation during rapid heating and cooling cycles. This attribute is particularly relevant for aerospace components, missile nose cones, and hypersonic vehicle skins, where materials are routinely subjected to hostile thermal environments.

Oxidation behavior represents a perennial challenge for ultra-high-temperature ceramics, as exposure to oxidative atmospheres at elevated temperatures leads to surface degradation and compromised structural integrity. Notably, the carbon fiber-reinforced zirconium diboride composites exhibited enhanced oxidation resistance. The research suggested that carbon fibers may contribute to forming a protective carbonaceous layer or influence the oxidation kinetics, thereby delaying mass loss and maintaining surface integrity. This oxidation resilience extends the operational lifespan of components, facilitating their use in harsh environments where conventional ceramics falter.

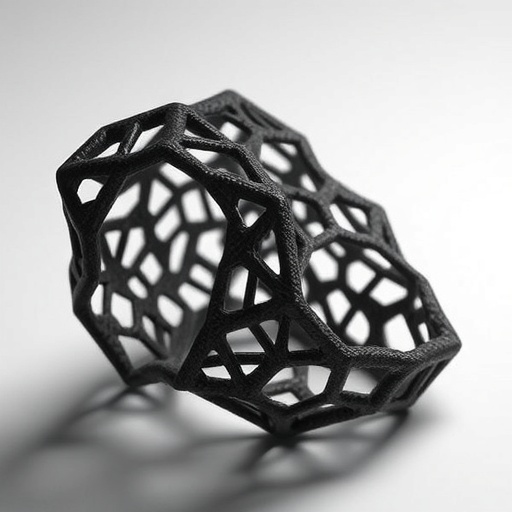

The integration of material extrusion additive manufacturing techniques played an instrumental role in realizing these advanced composites. Unlike powder metallurgy or traditional sintering, additive manufacturing allowed the fabrication of complex geometries with precise spatial distribution of carbon fibers. This enabled the production of near-net-shape components with minimal post-processing requirements. Furthermore, layer-by-layer deposition facilitated control over fiber orientation, which proved critical in optimizing anisotropic mechanical properties and thermal behaviors tailored for specific applications.

Scanning electron microscopy and microcomputed tomography imaging revealed that the carbon fibers were well dispersed within the zirconium diboride matrix, with minimal agglomeration or fiber damage during processing. The uniform distribution ensured consistent performance throughout the material and prevented localized weaknesses. Moreover, the interface between fibers and matrix exhibited strong bonding, essential for effective load transfer and durability, a feat achieved through controlled sintering parameters that promoted interfacial reactions without degrading fiber integrity.

The study’s comprehensive approach, combining carbon fiber reinforcement with optimized sintering and advanced manufacturing, sets a precedent for the development of next-generation ceramic composites. By addressing the long-standing issues of fragility and oxidation susceptibility, the research opens avenues for deploying zirconium diboride-based materials in extreme environments previously deemed unsuitable for ceramics. This will undoubtedly stimulate innovation in fields requiring materials that seamlessly blend strength, thermal stability, and manufacturability.

In addition to mechanical and thermal evaluations, the researchers conducted long-term stability tests, affirming that the reinforced composites sustain their elevated performance after prolonged exposure to cyclic thermal loads. Such durability is critical for real-world applications where materials endure repeated stress and temperature variations over extended service periods. The endurance under these conditions reinforces the practical relevance of this material system for industries pushing the boundaries of performance and safety.

Furthermore, the scalability of the material extrusion additive manufacturing process ensures that these advancements can transition from experimental labs to industrial production lines. By leveraging automated, digitally controlled fabrication, manufacturers can reproduce these complex composites with high reproducibility and efficiency. This scalability is a decisive factor in translating academic advancements into commercial products that influence market dynamics and technological progress.

Looking ahead, this research may catalyze further investigations into hybrid composites incorporating other reinforcement phases, such as ceramic fibers or nanoscale additives, to synergize with carbon fibers. The programmable nature of additive manufacturing allows such explorations, potentially unlocking even greater enhancements in mechanical and thermal properties. Moreover, adapting these methods to other ultra-high-temperature ceramics could revolutionize material science paradigms across diverse sectors.

The implications of this study ripple beyond materials science, impacting aerospace, defense, energy, and automotive industries. As demands for lightweight, durable, and resilient components escalate, materials like carbon fiber-reinforced zirconium diboride fabricated via next-generation additive techniques will become cornerstones of future engineering solutions. This fusion of advanced composites and precise manufacturing heralds a transformative era where capabilities once considered unattainable become reality.

In conclusion, the pioneering work on carbon fiber reinforcement and sintering optimization within material extrusion additive manufacturing frameworks represents a seismic shift in the fabrication and application of zirconium diboride ceramics. By systematically enhancing mechanical strength, thermal shock resistance, and oxidation behavior, this study not only resolves long-standing material challenges but also propels the field toward versatile, high-performance ceramic composites fit for the demands of tomorrow’s technology landscape.

Subject of Research: Enhancement of mechanical properties, thermal shock resistance, and oxidation behavior of zirconium diboride through carbon fiber reinforcement and sintering optimization using material extrusion additive manufacturing.

Article Title: Effect of carbon fiber reinforcement and sintering temperature on mechanical properties, thermal shock resistance, and oxidation behavior of zirconium diboride formed via material extrusion additive manufacturing.

Article References:

Kaufman, J., Wyckoff, C., Loughney, P.A. et al. Effect of carbon fiber reinforcement and sintering temperature on mechanical properties, thermal shock resistance, and oxidation behavior of zirconium diboride formed via material extrusion additive manufacturing. npj Adv. Manuf. 3, 2 (2026). https://doi.org/10.1038/s44334-025-00060-x

Image Credits: AI Generated

DOI: https://doi.org/10.1038/s44334-025-00060-x

Tags: 3D printing technologiesadditive manufacturing techniquesadvanced ceramic materialsaerospace material applicationscarbon fiber reinforcementHigh-temperature materialsmaterial extrusion methodsmechanical performance enhancementmicrostructure optimizationthermal stability ceramicszirconium diboride manufacturingzirconium diboride properties