In the realm of nanotechnology and microfabrication, the creation of intricate three-dimensional (3D) architectures at the nanoscale has long posed significant challenges, particularly concerning scalability and precision. Recent advancements, however, have begun to address these bottlenecks, heralding a new era for materials science, integrated microsystems, and miniaturized device engineering. Central to these breakthroughs is the innovative use of metalens arrays paired with sophisticated light modulation techniques, a combination that promises to revolutionize traditional two-photon lithography (TPL) methodologies.

The conventional frameworks of 3D laser nanofabrication have relied heavily on established imaging optics, which are inherently limited by their field of view (FOV). This constraint inevitably caps throughput and introduces errors such as proximity effects and stitching defects, particularly distressing when pursuing wafer-scale production or extensive microstructural printing. Addressing this challenge is paramount to advancing from laboratory-scale demonstrations to industrial-scale manufacturing, where consistency and efficiency assume critical importance.

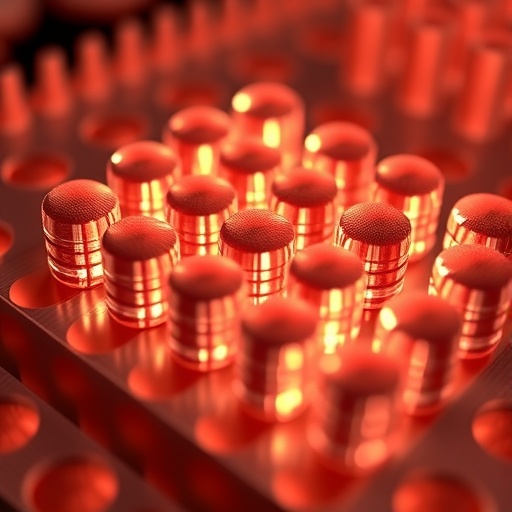

A novel nanofabrication platform has emerged that innovatively employs metalens arrays to generate expansive arrays of focal spots, enabling parallel processing in TPL. Metalenses, with their submicron focusing capabilities and high numerical apertures (NA), facilitate capacities previously unattainable by traditional lens systems. Critically, they are compatible with immersion media, a factor that typically enhances resolution and energy delivery at the focal plane, and their suitability for large-scale manufacturability positions them as ideal candidates for high-throughput assembly lines.

Through meticulous design and engineering, a system utilizing a metalens array spanning an impressive 12 square centimeters has been demonstrated, producing over 120,000 cooperative focal points simultaneously. This leap in parallelization fundamentally changes the throughput landscape, reaching volumes exceeding 10^8 voxels per second—a scale several orders of magnitude beyond existing TPL setups. Such advancement highlights the potential for mass production of nanostructures with true three-dimensional complexity.

Key to harnessing the metalens array’s capabilities is the integration of a spatial light modulator (SLM), which dynamically controls the illumination to each focal spot. This programmable modulation allows adaptive, greyscale linewidth tuning across the array, enabling delicately choreographed micro- and nanofabrication processes. The capacity to print both semi-periodic and fully aperiodic 3D geometries with high fidelity represents a substantial progression towards versatile, on-demand material structuring.

This adaptive parallel printing method sidesteps typical impedance challenges associated with uniform exposure strategies. Instead, the system selectively adjusts energy doses and exposure profiles in real-time, ensuring precise control over structural parameters such as linewidth and height at thousands of discrete points simultaneously. This is instrumental in achieving nanoscale resolution with feature sizes confirmed down to 113 nanometers—pushing the envelope of what can be fabricated via TPL.

The platform’s capabilities were rigorously validated through several compelling demonstrations, including the parallel printing of replicated microstructures at staggering rates exceeding 50 million microparticles per day. Beyond sheer production numbers, the technology excels in constructing centimeter-scale 3D architectures, where uniformity and resolution are preserved across large areas—a critical milestone towards industrial adoption.

Moreover, the technology has profound implications for the fabrication of photonic and mechanical metamaterials. These metamaterials require precise nanoscale patterning to manipulate electromagnetic waves and mechanical properties in tailored manners. The flexibility and resolution offered by the metalens-based approach enable the realization of complex metamaterial designs, potentially enhancing advances in optics, sensing, and novel material functionalities.

The combination of metalens arrays and spatially adaptive illumination not only opens new avenues for speed and scale but also introduces new precision standards previously unattainable. By enabling synchronized multibeam TPL processes, this approach fundamentally redefines the throughput limits while mitigating classic issues like stitching errors and field curvature that have hindered large-area nanofabrication.

The implications of this breakthrough transcend manufacturing, potentially impacting diverse fields such as microelectronics, biomedicine, and quantum technologies. In microelectronics, the ability to produce intricate nanoscale circuits and components at scale promises to accelerate progress in miniaturization and device performance. For biomedicine, precise 3D micro- and nanostructures can lead to improved drug delivery systems, scaffolds for tissue engineering, and diagnostic devices with enhanced functionality.

Additionally, quantum technology research stands to gain profoundly from these fabrication capabilities. Quantum information systems often require meticulously patterned nanostructures to manipulate quantum states and photons with high accuracy. The metalens-based TPL system holds promise to rapidly produce these architectures with unprecedented complexity and consistency.

Another exciting application lies in manufacturing high-energy laser targets, where precision and reproducibility at the nanoscale are vital to experimental and applied physics. The scalability and fidelity of this platform could ensure the reliable production of targets tailored to specific energetic and photonic criteria.

In summary, the marriage of metalens array-generated focal spots with spatial light modulation paves the way for scalable, high-resolution, high-throughput 3D nanolithography. By surmounting fundamental optical and fabrication limitations, this technology sets a new benchmark in nanomanufacturing, with vast potential to reshape multiple scientific and industrial landscapes. As research moves forward, this innovative platform stands poised to transition TPL from a primarily research-based technique into a robust, scalable fabrication method ready to meet the demands of the future of nanotechnology and beyond.

Subject of Research:

Article Title:

Article References:

Gu, S., Mao, C., Guell Izard, A. et al. 3D nanolithography with metalens arrays and spatially adaptive illumination. Nature 648, 591–599 (2025). https://doi.org/10.1038/s41586-025-09842-x

Image Credits: AI Generated

DOI: 18 December 2025

Keywords

Tags: 3D nanolithography techniquesadaptive illumination in nanofabricationchallenges in nanoscale architectureenhancing resolution with metalensesindustrial-scale nanofabricationinnovative light modulation methodsmetalens array applicationsovercoming proximity effects in lithographyparallel processing in microstructural printingprecision engineering in materials sciencescalable microfabrication solutionstwo-photon lithography advancements