In a remarkable breakthrough that could redefine the future of wearable and flexible electronics, a team of researchers led by Yang, Liu, and Pan has developed highly foldable and leakage-free electrodes leveraging ultrathin liquid metal micromeshes. Published in npj Flexible Electronics, this cutting-edge study addresses some of the longstanding challenges related to flexibility, conductivity, and durability in the domain of advanced electronic materials.

Flexible electronics have attracted substantial interest due to their potential applications in healthcare, robotics, and consumer electronics. However, a persistent obstacle has been fabricating electrodes that retain performance under extreme mechanical deformation while preventing leakage issues, which degrade device reliability. The newly introduced ultrathin liquid metal micromeshes pave the way toward overcoming this barrier by combining the advantageous properties of liquid metals with precisely engineered mesh-like structures.

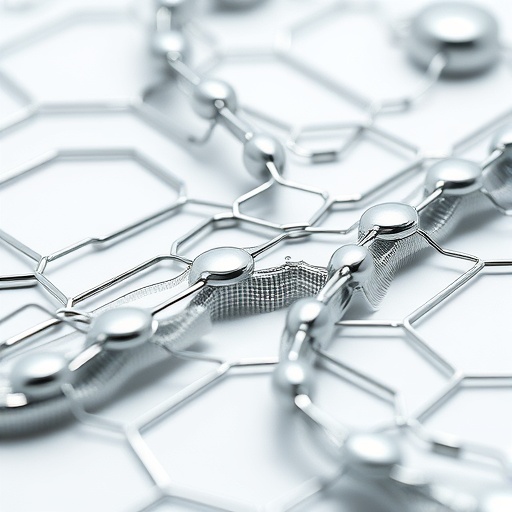

Liquid metals, such as gallium-based alloys, are known for their excellent electrical conductivity and inherent fluidity at room temperature, which can offer exceptional deformability. Yet, conventional approaches with bulk liquid metals often suffer from leakage when the material flows out of designated regions during bending or folding, thus compromising device integrity. Yang and colleagues have ingeniously tackled this challenge by sculpting the liquid metal into an ultrathin micromesh – an interconnected network of metal threads arranged with nanoscale precision.

The fabrication process involves advanced patterning techniques that produce micrometer-wide metal filaments structured into a mesh that supports both mechanical strain and electrical conductivity. The ultrathin nature of this mesh allows it to bend and fold without significant loss of electrical performance. Crucially, the mesh architecture confines the liquid metal, preventing leakage even under extensive mechanical deformation. This innovation represents a significant conductivity vs. flexibility trade-off improvement that had eluded material scientists until now.

Testing these electrodes under rigorous bending, folding, and stretching conditions revealed minimal changes in electrical resistance, showcasing astounding durability. Unlike previous attempts where electrodes would rupture or leak under similar mechanical stress, these ultrathin liquid metal micromeshes maintained stable electrical characteristics. Furthermore, the researchers demonstrated that the electrodes could be integrated with various flexible substrates, including elastomers and polymers, without compromising their foldability or electrical functionality.

The implications of these highly foldable and leakage-free electrodes extend far beyond traditional electronics. They offer promising applications in flexible displays, next-generation wearable health monitors capable of continuous biometric sensing, and soft robotics where circuits must endure repeated and complex mechanical movements. The ability to fold electrodes without performance loss enables more compact designs and novel form factors not possible with rigid or semi-rigid materials.

From a materials science perspective, this approach encapsulates the synergy between nanoscale engineering and intrinsic material properties. The micromesh works as a mechanical and structural scaffold, distributing strain more evenly and preventing localized stress concentrations that typically cause damage or leakage in bulk liquid metal conductors. This biomimetic design mirrors natural materials’ hierarchical architectures, where flexibility and strength coexist through organized networks of nanoscale fibers.

By employing state-of-the-art characterization methods, including scanning electron microscopy and electrical impedance spectroscopy, the team meticulously analyzed the physical integrity and electrical uniformity of the micromeshes after multiple deformation cycles. The results consistently indicated excellent resilience, validating the robustness required for commercial device applications. Additionally, the research highlighted the compatibility of these electrodes with existing fabrication processes, suggesting seamless integration into scalable manufacturing pipelines.

Another noteworthy aspect of this study is the environmental stability of the developed electrodes. Liquid metals are often sensitive to oxidation and surface contamination, potentially impairing conductivity over time. However, the ultrathin micromesh geometry coupled with protective polymer encapsulation efficiently protects the materials from environmental degradation, enhancing longevity and operational stability. This feature is pivotal for wearable and implantable devices exposed to sweat, humidity, and temperature fluctuations.

The team also addressed concerns related to biocompatibility and safety, especially important for devices in direct contact with human skin. Preliminary biocompatibility assessments indicated minimal cytotoxicity and skin irritation, opening doors for medical-grade flexible electronics and epidermal sensors that require both comfort and performance. The ultrathin profile contributes positively by reducing mechanical impedance when adhered to complex skin surfaces.

In terms of fundamental science, the successful demonstration of leakage-free liquid metal micromeshes challenges preconceived notions about liquid metals’ application limits in flexible electronics. It expands the design space for conductive materials by proving that liquid state metals can be precisely controlled and confined, transforming them from a liquid liability into a mechanical asset. This paradigm shift encourages exploration of other liquid or hybrid metal systems for future innovations.

Moreover, the concept of ultrathin micromeshes can be extended beyond electrodes to other functional components such as antennas, interconnects, and sensors. The principles uncovered in this research can inform the development of multifunctional flexible electronic platforms where mechanical durability and electrical performance are paramount. Emerging technologies like soft neural interfaces, stretchable energy harvesters, and flexible photovoltaics could all benefit from adapting the micromesh methodology.

This breakthrough is poised to inspire accelerated development in flexible electronics, catalyzing new product designs that combine performance, comfort, and robustness. As consumer demand grows for devices that conform seamlessly to the human body while maintaining high-functionality, solutions like Yang et al.’s ultrathin liquid metal micromesh electrodes offer a timely and transformative leap forward. Their work marks a critical step toward realizing the long-sought vision of electronics that are not only flexible but also enduring and safe.

Looking ahead, future research will likely focus on optimizing material compositions, refining the micromesh architecture for specific applications, and scaling up production for commercial deployment. Integration with wireless communication modules and energy storage units could yield fully autonomous wearable systems. Furthermore, cross-disciplinary collaboration involving materials science, mechanical engineering, and biomedicine will be essential to unlock the full potential of this novel electrode technology.

In summary, the introduction of highly foldable and leakage-free electrodes made possible by ultrathin liquid metal micromeshes redefines the standards and expectations in flexible electronic materials. Yang, Liu, Pan, and their team have demonstrated a practical route to engineer liquid metals in ways that leverage their fluidity without succumbing to leakage, delivering unprecedented mechanical flexibility combined with stable electrical performance. Their contribution not only advances fundamental science but also accelerates the practical realization of next-generation flexible electronics that will redefine how humans interact with technology.

Article References:

Yang, X., Liu, H., Pan, T. et al. Highly foldable and leakage-free electrodes enabled by ultrathin liquid metal micromeshes. npj Flex Electron (2025). https://doi.org/10.1038/s41528-025-00510-8

Tags: advanced electronic materials researchchallenges in flexible electronicsconductivity and durability in electronicsflexible electronics advancementsfoldable electrodes technologygallium-based alloys applicationsinnovative electrode fabrication methodsleakage-free electrode designmechanical deformation in electronicsnpj Flexible Electronics publicationultrathin liquid metal micromesheswearable electronic devices