In the realm of industrial engineering and operations research, effective layout planning plays a crucial role in increasing productivity and ensuring safety within manufacturing environments. Recent developments highlight a new mathematical model introduced to tackle the complexities of multi-row layout problems. This innovative model aims not only to minimize material handling costs but also to incorporate crucial safety factors, which are often overlooked in traditional layout optimization methodologies.

At the core of this research is the recognition that optimizing machine placement is a multifaceted challenge. Within large production facilities, machines often need to be organized in a manner that facilitates smooth workflow while maintaining sufficient safety distances between them. This is especially vital in settings where operational machinery can pose risks to personnel if proper spacing is not adhered to. The newly proposed approach addresses these dilemmas by formulating a problem that integrates both cost efficiency and safety considerations.

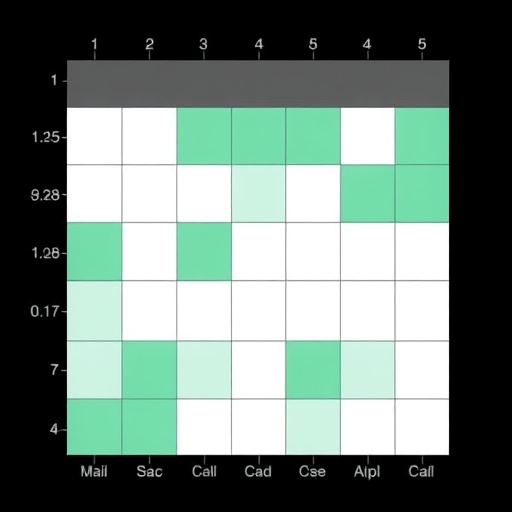

The model introduces a two-stage heuristic designed for solving the multi-row layout problem effectively. The first stage employs an Improved Variable Neighborhood Search (IVNS) method to strategically allocate machines across two designated rows. This technique involves moving between various configurations of machine placements, systematically exploring the solution space while ensuring that the necessary safety boundaries are maintained. The IVNS is particularly useful as it allows for a more flexible yet systematic approach to machine positioning.

Following the initial allocation in the first stage, the second phase utilizes the Sine Cosine Algorithm (SCA), a robust optimization algorithm known for its effectiveness in dealing with continuous and discrete problems. This stage focuses on fine-tuning the machine placements by optimizing the boundary clearances and establishing the foundational points for each row. The incorporation of boundary adjustments is key to maximizing productivity and minimizing costs, as it enables deeper exploration of layout configurations that standard algorithms might overlook.

The computational experiments conducted within this study reveal compelling evidence regarding the efficacy of the proposed IVNS-SCA method. It consistently outperforms traditional single-stage approaches such as Simulated Annealing (SA) and the General Variable Neighborhood Search (GVNS). This performance advantage becomes even more pronounced when examining larger instances of layout problems, where the complexities and scale of operations amplify the challenges of both cost management and safety compliance.

With rigorous testing against these established algorithms, the IVNS-SCA method not only achieved better objective values but also demonstrated significant improvements in solution quality. The study identified average enhancements of 0.9% compared to the SA-SCA, 1.9% compared to the standard SA, and improvements ranging from 1.1% to 5.3% in various configurations compared to GVNS-based algorithms. These results highlight the superior capacity of the proposed methodology to navigate the solution space effectively, thereby allowing users to make informed decisions that enhance both profitability and safety in production environments.

Such advancements affirm the relevance of incorporating sophisticated algorithms into industrial operations research. By bridging the gap between theoretical models and practical application, this research helps manufacturing entities optimize their layouts more effectively while ensuring compliance with safety regulations. The implications of this research extend beyond mere cost savings; they also promise to foster safer work environments and promote better operational standards across the industry.

Despite these promising findings, the authors caution that the search for optimal solutions is still an ongoing process, particularly in smaller instances of the problem. While the proposed metaheuristics exhibit commendable performance, there remains a pressing need for the development of efficient mathematical frameworks and exact methods capable of delivering definitive optimal solutions within reasonable timeframes. This pursuit of refinement underscores the evolving nature of operations research and the necessity of continuous innovation in the field.

Future research avenues may explore the integration of other advanced algorithms, particularly those that incorporate artificial intelligence and machine learning. This intersection of technology and industrial engineering holds the potential to revolutionize how layout problems are approached, enabling even more profound insights and optimizations. Researchers are also encouraged to examine real-world applications of these methodologies, assessing their practicality and adaptability in various industries.

In summary, the introduction of a two-stage improved variable neighborhood search coupled with a sine cosine algorithm marks a significant stride in addressing the multi-row layout problem. By blending material handling cost reduction with safety considerations, this model presents a comprehensive solution that could redefine layout planning methodologies in manufacturing. As industries grapple with increasingly complex operational environments, such innovative approaches are instrumental in steering towards safer, more efficient production systems.

In an era where efficiency and safety are paramount, this research stands as a testament to the ongoing evolution within the context of industrial operations. The collaborative nature of mathematical modeling combined with heuristic algorithms not only advances academic inquiry but also holds substantial implications for practical application across the manufacturing landscape.

Through concerted efforts in research and development, the journey towards achieving optimal solutions for multi-row layout problems exemplifies the remarkable progress within the field of operations research, promising enhanced productivity and safety standards for future generations.

Subject of Research: Multi-row layout problems and machine placement optimization.

Article Title: A two-stage improved variable neighborhood search-sine cosine algorithm for the multi-row layout problem with safety consideration.

Article References:

Rifai, A.P., Sari, W.P. A two-stage improved variable neighborhood search-sine cosine algorithm for the multi-row layout problem with safety consideration. Sci Rep 15, 39186 (2025). https://doi.org/10.1038/s41598-025-25551-x

Image Credits: AI Generated

DOI: https://doi.org/10.1038/s41598-025-25551-x

Keywords: layout optimization, industrial engineering, operations research, material handling, safety factor, heuristic algorithms, variable neighborhood search, sine cosine algorithm.

Tags: cost-efficient production layoutsheuristic methods in operations researchImproved Variable Neighborhood Searchindustrial engineering layout planninginnovative approaches to industrial layout designlayout planning for manufacturing environmentsmachine placement strategiesmathematical model for manufacturingmulti-row layout optimizationproduction facility workflow optimizationsafety distance in machine arrangementsafety factors in layout design