In a groundbreaking advancement that could redefine carbon capture and utilization, scientists from Sun Yat-Sen University have unveiled a pioneering technology that electrochemically converts carbon dioxide (CO₂) directly from air and flue gas into high-purity formic acid. This innovation addresses one of the most formidable challenges in sustainable chemistry — harnessing dilute CO₂ sources efficiently, bypassing the need for energy-intensive pre-purification processes. By integrating a metal-organic framework (MOF)-based molecular sieve membrane directly into the electrolyzer system, the researchers have transformed CO₂ conversion into a more economically and environmentally viable process with profound implications for carbon neutrality efforts worldwide.

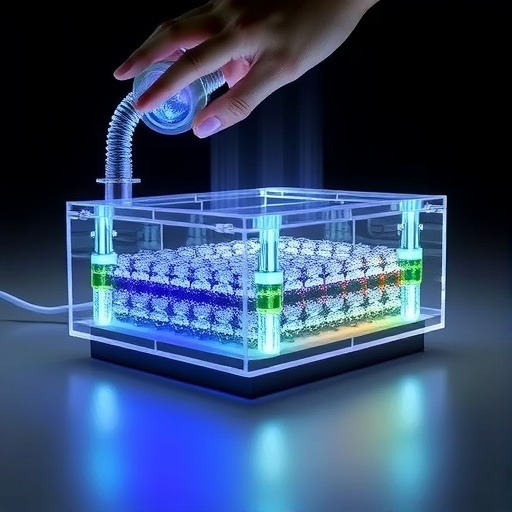

Traditional electrochemical reduction of CO₂ has depended extensively on purified sources, often requiring costly and complex downstream treatment to isolate CO₂ from mixtures with nitrogen, oxygen, sulfur dioxide, and other impurities. These steps impose significant energy penalties and economic burdens that limit scalability and commercialization. The innovation spearheaded by Professors Xiao-Ming Chen and Pei-Qin Liao leverages the uniquely porous and selective properties of MOFs, crystalline materials constructed from metal ions coordinated with organic ligands, to revolutionize this paradigm. Their self-supporting mixed-matrix membrane acts as a dual-function unit: it both filters out undesirable gaseous contaminants and concentrates CO₂ from dilute sources directly within the electrolyzer environment.

This selective membrane’s proficiency was demonstrated under challenging conditions by treating flue gas typically consisting of roughly 15% CO₂. The MOF membrane heightened the CO₂ concentration dramatically to approximately 82.5%, a level conducive to efficient electrochemical reduction. Crucially, this in situ enrichment allows the downstream electrolyzer, outfitted with a bismuth nanoparticle catalytic layer, to convert the enriched CO₂ into formic acid (HCOOH) with nearly perfect Faradaic efficiency, reaching currents as high as 9000 mA. Over just a four-hour period, the system successfully produced 23 milliliters of anhydrous, electrolyte-free formic acid that meets stringent commercial purity standards. Notably, this marks the first recorded instance of such direct electrochemical transformation taking place from raw flue gases.

Even more striking is the device’s ability to process ambient air — where CO₂ levels fall precipitously to a mere 0.04%. By employing an alternate MOF membrane variant named KAUST-7, renowned for its exceptional selective adsorption characteristics, the researchers were able to elevate CO₂ concentration in air to 2.05%. This resulted in a Faradaic efficiency of 98.2% for formic acid production, with a yield rate that surpassed similar catalyst systems lacking membrane integration by a factor of 5,000. The implications for this capability are significant, opening avenues for closed or confined environments such as submarines and space stations, where maintaining air quality and managing CO₂ levels are critical operational concerns.

Electrochemical conversion to formic acid is especially advantageous due to the compound’s multifaceted utility. As a liquid fuel, formic acid possesses superior energy density and transportability compared to gaseous alternatives. It also serves as a versatile industrial chemical, lending itself to applications spanning from fuel cells to feedstocks for pharmaceuticals. The ability to produce this substance directly from waste CO₂ enhances circular carbon utilization, thus reducing atmospheric CO₂ levels while simultaneously generating valuable commodities.

Beyond the evident performance metrics, this integrated membrane-electrolyzer design confers substantial economic benefits. The elimination of pre-purification steps translates into a reduction of about 15% in production costs when using flue gas instead of pure CO₂. Such a cost advantage could catalyze broader industrial adoption. Furthermore, the selective filtering nature of the MOF membrane safeguards the catalytic environment by preventing side reactions caused by gaseous contaminants, thus ensuring consistent and durable operation, a major hurdle for many electrochemical systems working under real-world conditions.

This research merges sophisticated materials science with advanced electrochemical engineering, symbolizing a crucial nexus toward deployable carbon capture and utilization solutions. Feasible integration of this technology into existing industrial setups could see power plants and factories achieving near-real-time conversion of their CO₂-intensive emissions into market-ready formic acid, mitigating carbon footprints while creating new value streams. The prospect of direct air capture coupled with efficient electrochemical reduction foretells a future where decentralized, low-cost carbon recycling units could become a common fixture.

Scientifically, the employment of MOF membranes as molecular sieves is transformative. These materials have long fascinated researchers due to their tunability and high surface areas. However, their implementation as integral, self-supporting membranes inside electrolyzers represents an innovative leap. By tailoring pore sizes and chemical affinities, the membranes exhibit exceptional selectivity for CO₂ over competing gases like nitrogen and oxygen, a requirement only recently realized in scalable formats. This work exemplifies the maturation of MOFs from laboratory curiosities to industrially relevant materials.

The catalytic layer of bismuth nanoparticles further fortifies the system’s efficiency. Bismuth is known for its robust catalytic activity in facilitating CO₂ reduction to formic acid with high selectivity. Coupled with the enriched CO₂ environment created by the MOF membrane, the catalyst operates optimally, suppressing hydrogen evolution and other parasitic reactions. This synergy between membrane and catalyst epitomizes thoughtful interdisciplinary design that can unlock unprecedented performance in CO₂ conversion technologies.

Importantly, the reproducibility and stability of the system bolster its technological credibility. Sustained operation without degradation over multiple cycles confirms that the MOF membranes maintain their structural and functional integrity even under acidic and electrochemical conditions. Such durability is critical for translating laboratory successes into commercial deployments where continuous operation and maintenance costs dictate viability.

Environmental sustainability is at the heart of this advancement. By harnessing waste CO₂ streams or even ambient air, the technology minimizes carbon emissions and replaces fossil-fuel-derived chemical synthesis routes. This alignment with circular economy principles strengthens global efforts toward achieving net-zero emissions. Moreover, the potential deployment in closed habitats extends its relevance into emerging fields like long-duration space missions, where resource recycling is not optional but mandatory.

Looking ahead, this study lays the groundwork for future enhancements in system scalability and integration. Further optimization of MOF membrane compositions, coupling with renewable electricity sources, and combining with downstream separation techniques are anticipated to move technology readiness levels toward commercial market entry. Collaboration between material scientists, chemical engineers, and industrial players will be pivotal in these next steps.

The research was conducted at the MOE Key Laboratory of Bioinorganic and Synthetic Chemistry at Sun Yat-Sen University, a leading institution renowned for its commitment to addressing energy and environmental challenges through cutting-edge materials and process innovation. This work not only embodies academic excellence but also reflects a tangible contribution toward realizing global carbon neutrality goals.

In summary, the integration of a self-supporting MOF-based membrane within an electrolyzer that converts dilute CO₂ to commercially pure formic acid is a landmark achievement. It signifies a shift toward practical carbon capture and utilization strategies that combine selectivity, efficiency, and economic feasibility. Such breakthroughs underscore the potential to transform current carbon management practices and elevate sustainable chemical manufacturing to new heights.

Subject of Research: Electrochemical conversion of dilute CO₂ sources to formic acid using MOF-based molecular sieve membranes integrated in electrolyzers.

Article Title: [Not provided in the source content]

News Publication Date: [Not provided in the source content]

Web References:

http://dx.doi.org/10.1093/nsr/nwaf329

References:

National Science Review, DOI: 10.1093/nsr/nwaf329

Image Credits:

©Science China Press

Keywords

Carbon dioxide conversion, electrochemical reduction, formic acid production, metal-organic frameworks, MOF membranes, mixed-matrix membrane, bismuth nanoparticle catalyst, flue gas treatment, air capture, sustainable chemistry, carbon neutrality, energy efficiency, gas separation technology

Tags: carbon capture and utilization advancementsdirect air capture systemsdual-function membrane technologyeconomic viability of carbon neutralityelectrochemical conversion of CO₂energy-efficient carbon capture methodsflue gas CO2 utilizationformic acid production from CO2MOF membrane electrolyzer technologyscalability of CO2 conversion processesSun Yat-Sen University research breakthroughssustainable chemistry innovations