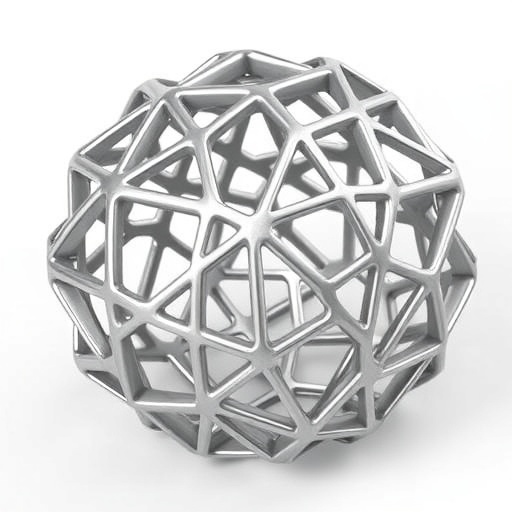

The realm of metallic triply periodic minimal surface (TPMS) lattice structures has been revolutionized by the advent of additive manufacturing technologies. These complex geometries, once deemed nearly impossible to fabricate with traditional methods, have now become feasible due to the precision and flexibility offered by modern 3D printing techniques. However, despite this transformative progress, numerous technical challenges and limitations continue to constrain their widespread adoption and optimal performance. Understanding these challenges is critical for pushing the boundaries of design, fabrication, and functional application in advanced manufacturing industries.

At the heart of the difficulties lies the geometric design phase. While contemporary computer-aided design (CAD) tools provide opportunities to explore intricate lattice configurations, the freedom is far from absolute, especially for highly complex TPMS structures. Current algorithms predominantly rely on Boolean operations for model construction, which drastically ramp up computational demands. These operations consume excessive processing power and memory, leading to execution bottlenecks and frequent interruptions when attempting to generate elaborate TPMS geometries. This computational overhead restricts rapid design iterations and hinders the timely development of optimized lattice architectures tailored to specific functional requirements.

Once the designs are generated, the transition from virtual models to physical structures presents another set of challenges. Additive manufacturing processes, including laser-powder bed fusion (L-PBF), micro laser powder bed fusion (μLPBF), material extrusion additive manufacturing (MEAM), and binder jetting, each carry inherent limitations that directly affect the quality of fabricated metallic TPMS lattices. For instance, L-PBF methods often leave partially melted or unmelted powder adhering to intricate surfaces, increasing roughness and serving as potential crack initiation points—weakening structural integrity under mechanical stress. Even the more precise μLPBF does not fully overcome powder adhesion issues, posing persistent reliability concerns for load-bearing applications.

MEAM presents a cost-effective alternative adapted for TPMS fabrication but sacrifices dimensional precision and is highly sensitive to process parameters, complicating repeatability and quality control. Binder jetting, while efficient and affordable, suffers from binder infiltration at the boundaries of lattice features, compromising dimensional accuracy and surface finish. Intriguingly, this issue remains resistant to simple scaling adjustments in the print files, limiting the potential to manufacture the ultra-fine geometries and smooth surfaces required for advanced engineering components. These manufacturing-induced imperfections necessitate carefully controlled post-processing strategies that balance improving surface quality against maintaining the delicate lattice integrity.

Beyond manufacturing constraints, the evaluation and optimization of metallic TPMS lattices have predominantly concentrated on uniform structures, neglecting the high potential of graded or heterogeneous arrangements. Mechanical testing frequently relies on compression testing due to its relative simplicity and repeatability, but this singular focus may miss critical insights. Tensile fatigue testing, in contrast, offers a nuanced understanding of structural deformation and fatigue behavior—factors paramount for materials subjected to cyclic loading in real-world applications. Expanding the scope of mechanical analyses to embrace fatigue and other complex testing methods is essential to more comprehensively characterize the multifunctional properties of these innovative lattices.

Heat and mass transfer properties represent another frontier in TPMS research, particularly relevant for applications such as thermal management, filtration, and catalysis. The complex internal topologies associated with heterogeneous and externally contoured TPMS lattices influence fluid flow and thermal conductivity in ways that are not yet fully understood. Investigations into these transport phenomena remain sparse, representing a critical knowledge gap that, when addressed, could unlock new multifunctionality and performance optimization opportunities for metallic TPMS structures in varying industrial sectors.

Design optimization, specifically topology optimization, further complicates the landscape. Although capable of enhancing performance by systematically modifying lattice geometries, topology optimization is computationally intensive and iterative in nature. Current methods often produce two-dimensional density results that lack real-world applicability due to insufficient precision. Real engineering scenarios introduce additional constraints, such as manufacturability limits, that increase computational complexity. Overcoming these challenges requires novel algorithms that provide efficient, highly accurate optimization that respects both the complex nature of TPMS lattices and the practical limitations of additive manufacturing equipment.

The multidisciplinary nature of metallic TPMS lattice design underscores the importance of integrating materials science, mechanical engineering, computational modeling, and thermal-fluid sciences into a cohesive research framework. The necessity of balancing competing performance factors—such as mechanical strength, thermal management, and porosity—demands collaborative approaches that span traditional disciplinary boundaries. By coordinating efforts in design, fabrication, and performance characterization, the creation of functionally optimized TPMS lattices with tailored porosity gradients and material distributions becomes achievable.

Nevertheless, the lack of standardized guidelines and protocols remains a critical bottleneck for the field. Unlike other lattice structures with established standards, metallic TPMS lattices suffer from data inconsistency and incomparable results due to the absence of unified assessment criteria. From the design viewpoint, the community requires standardized parametrization frameworks rooted in topology classification and rating systems, ideally supported by ISO or ASTM standards. On the manufacturing front, defining a consistent printing process window—accounting for geometry variations and machine calibrations—would substantially reduce variability and improve reproducibility.

Testing and characterization inconsistencies exacerbate these challenges. Non-standardized mechanical testing protocols, insufficient surface quality metrics, and disparate porosity measurement techniques hinder the objective evaluation and cross-study comparability of TPMS lattice materials. The establishment of comprehensive, unified testing methodologies is imperative to generate reliable, benchmarked performance data and accelerate adoption in industry applications.

Looking forward, advancements in computational power, machine learning-assisted design, and process monitoring could mitigate many existing issues in geometric design and manufacturing control. Intelligent algorithms capable of efficiently handling the complexity of Boolean operations without resource exhaustion will enable faster and more intricate TPMS lattice generation. Similarly, real-time process control and adaptive post-processing strategies can address surface roughness and defect mitigation effectively, ensuring high-quality outputs that maintain structural integrity under demanding operational conditions.

Furthermore, expanding mechanical testing regimes to include tensile fatigue and multi-physics analyses will deepen understanding of deformation mechanisms and multifunctional behavior, guiding the development of TPMS lattices for diverse industrial domains—ranging from aerospace components requiring high strength-to-weight ratios to biomedical implants needing optimized heat and mass transfer properties. Concurrently, progress in topology optimization algorithms tailored to the constraints of additive manufacturing will drive the creation of lattices with unprecedented performance customization.

Fundamentally, the transition of metallic TPMS lattice structures from promising laboratory technologies to robust industrial solutions hinges upon enhanced collaboration across disciplines and the institution of standardized frameworks. Coordinated efforts that converge materials science insights, mechanical engineering principles, manufacturing technology, and international standards will pose metallic TPMS lattices as cornerstones of future multifunctional material systems. Through these multifaceted endeavors, the transformative potential of additively manufactured metallic TPMS lattices can be fully realized, paving the way for innovative applications across sectors.

In conclusion, while additive manufacturing has unlocked the capability to produce sophisticated metallic TPMS lattice structures, a constellation of challenges spanning design, fabrication, testing, optimization, and standardization remains. Addressing these barriers requires not only technological innovation but also integrated research strategies and standard development initiatives. As the field advances, overcoming these obstacles will enable metallic TPMS lattices to achieve their promise as versatile, high-performance materials for the next generation of manufacturing and engineering applications.

Subject of Research: Metallic Triply Periodic Minimal Surface (TPMS) Lattice Structures and their Additive Manufacturing Challenges and Applications

Article Title: Additively manufactured metallic TPMS lattice structures: design strategies, fabrication, multifunctional properties, and applications

Article References:

Li, J., Wang, L., He, X. et al. Additively manufactured metallic TPMS lattice structures: design strategies, fabrication, multifunctional properties, and applications. npj Adv. Manuf. 2, 45 (2025). https://doi.org/10.1038/s44334-025-00057-6

Image Credits: AI Generated

Tags: 3D-printed metallic TPMS latticesadditive manufacturing technologiesadvanced manufacturing applicationscomputational demands in lattice designcomputer-aided design for latticesfabrication of complex geometriesfunctional applications of TPMS structuresgeometric design challengesoptimization of lattice architecturestechnical limitations in 3D printingtransitions from virtual to physical modelstriply periodic minimal surface structures