In the ever-evolving landscape of regenerative medicine, recombinant human type III collagen (rhCol III) is emerging as a transformative biomaterial with vast potential for tissue engineering applications. Traditionally sourced from animal collagen, type III collagen plays a crucial role in maintaining tissue integrity and facilitating repair. Now, through advances in genetic engineering, laboratories can produce rhCol III on a molecular level, opening new frontiers for biomedical innovation. This development offers unprecedented control over collagen’s properties, setting the stage for breakthroughs in wound healing, skin repair, and anti-inflammatory therapies that could revolutionize patient outcomes.

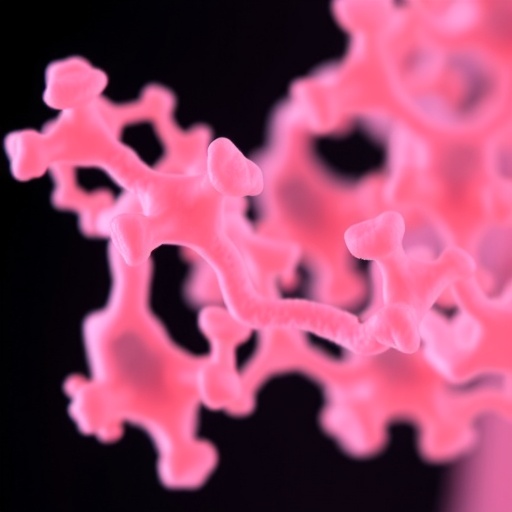

Type III collagen is one of the primary structural proteins found in connective tissues such as skin, blood vessels, and internal organs. Its significance stems from its ability to form fibrillar networks that support cellular adhesion and migration, essential processes during tissue regeneration. Unlike its type I counterpart, type III collagen ensures flexibility and elasticity within tissues, making it particularly valuable for engineering dynamic soft tissues and organs that undergo constant mechanical stress. Recombinant techniques now enable the production of purified, pathogen-free forms of type III collagen, overcoming the limitations of animal-derived collagen such as immunogenicity and batch variability.

The synthesis of rhCol III involves inserting human genes encoding the type III pro-collagen into microbial or mammalian expression systems. By leveraging these biotechnological platforms, researchers can tailor the collagen’s biochemical and mechanical properties through genetic modifications. This level of customization is critical for designing scaffolds that not only mimic the extracellular matrix but also enhance specific cellular responses such as proliferation and differentiation. These genetically engineered collagens have demonstrated superior biocompatibility and bioactivity, crucial metrics for any implantable biomaterial intended for clinical translation.

One of the most promising applications of rhCol III lies in bone tissue engineering. While type I collagen dominates the mineralized extracellular matrix of bone, type III collagen’s early role during the healing cascade is indispensable. Incorporating rhCol III into composite scaffolds enhances vascularization and osteoprogenitor cell recruitment, accelerating the healing process of critical-sized bone defects. Moreover, rhCol III’s unique molecular configuration allows it to interact synergistically with growth factors, amplifying regenerative signaling pathways. Emerging studies reveal that rhCol III-based scaffolds promote not only structural recovery but also functional restoration of bone architecture.

Soft tissue engineering is another vibrant frontier where rhCol III shows immense promise. The innate elasticity and biocompatibility of type III collagen render it ideal for engineering tissues such as skin, blood vessels, and tendons. In chronic wound healing, for instance, rhCol III scaffolds provide a bioactive matrix that supports fibroblast infiltration, angiogenesis, and epithelialization. Its natural anti-inflammatory properties reduce prolonged tissue damage and scarring, which are common complications with synthetic or animal-derived materials. As a result, patients experience faster recovery times and reduced incidence of infection, marking a significant clinical advancement.

Another groundbreaking dimension of rhCol III is its role in modulating inflammatory responses during tissue repair. Inflammation is a double-edged sword in healing—essential for clearing damaged cells but detrimental if chronic or excessive. Recombinant type III collagen has been found to interact with immune cells, shifting the local microenvironment towards a resolution phase that favors regeneration over fibrosis. This immunomodulatory capability makes rhCol III an attractive candidate for treating inflammatory diseases and enhancing graft integration in transplant surgeries, paving the way for personalized regenerative therapies.

Despite its many advantages, the clinical translation of rhCol III faces considerable challenges, particularly regarding mechanical performance. Type III collagen’s inherently softer and more compliant nature can compromise structural stability in load-bearing applications. Researchers are actively exploring strategies to augment its tensile strength, such as cross-linking techniques or hybridizing with other biomaterials like synthetic polymers. Fine-tuning these composite constructs is essential to achieve the delicate balance between rigidity and elasticity that native tissues require, ensuring both safety and functionality post-implantation.

Production efficiency also remains a significant hurdle on the path to widespread clinical implementation. While genetic engineering allows precision in collagen synthesis, scaling production to meet commercial demand without loss of bioactivity or purity is complex. Innovations in bioreactor design and fermentation parameters are being investigated to optimize yield and reduce costs. Advances in purification technologies aim to eliminate endotoxins and contaminants, which are critical for regulatory approval and patient safety. Addressing these manufacturing challenges is paramount for transforming rhCol III from a laboratory curiosity into a clinical mainstay.

Ethical and regulatory considerations around the use of recombinant proteins also influence the development trajectory of rhCol III. Unlike collagens derived from animal sources, recombinant technology mitigates concerns related to zoonotic infections and immune rejection. However, thorough long-term biocompatibility studies and compliance with stringent clinical guidelines are necessary before full-scale deployment. Multi-disciplinary collaborations among bioengineers, clinicians, and regulatory bodies will be vital to navigate these complexities, enabling responsible innovation that prioritizes patient welfare.

Looking ahead, the integration of recombinant collagen technology with cutting-edge tools such as 3D bioprinting and gene editing holds tremendous potential. Customized tissue constructs embedded with rhCol III could be fabricated with unparalleled precision, matching patient-specific anatomical and biomechanical requirements. Additionally, gene-editing strategies might further enhance collagen production or introduce novel functional domains to promote healing. These futuristic approaches could solve persistent challenges faced by conventional tissue engineering, heralding a new era of personalized regenerative medicine.

In summary, recombinant human type III collagen represents a powerful biomaterial platform at the intersection of biotechnology and regenerative medicine. Its excellent biocompatibility, bioactivity, and potential for customization present compelling opportunities for developing advanced therapies across diverse tissue types. From accelerating bone repair to improving chronic wound management and modulating inflammation, rhCol III’s versatility is reshaping the paradigm of tissue engineering. Although technical and translational challenges remain, ongoing research promises to unlock its full clinical potential, moving closer to the day when damaged tissues can be seamlessly restored with lab-grown collagen scaffolds.

As this field evolves, ongoing investments in mechanistic studies, production innovation, and clinical trials will be crucial. The goal is to enhance not only the structural fidelity of engineered tissues but also their functional integration within the host. Recombinant type III collagen is poised to catalyze these advances, embodying the power of synthetic biology to create life-sustaining materials that heal from within. The medical community and patients alike eagerly anticipate the broader adoption of these biomimetic constructs, hoping for improved healing outcomes that redefine regenerative therapies in the decades to come.

Subject of Research: Recombinant human type III collagen and its applications in tissue engineering

Article Title: Applications of recombinant type III collagen in tissue engineering

Article References: Shan, Y., Wang, T. & Lin, H. Applications of recombinant type III collagen in tissue engineering. BioMed Eng OnLine 24, 114 (2025). https://doi.org/10.1186/s12938-025-01447-9

Image Credits: AI Generated

DOI: https://doi.org/10.1186/s12938-025-01447-9

Keywords: recombinant human type III collagen, tissue engineering, regenerative medicine, wound healing, bone repair, soft tissue scaffolds, bioactivity, biocompatibility, inflammation modulation, biomaterials technology

Tags: anti-inflammatory therapiescollagen properties controlconnective tissue structural proteinsdynamic soft tissue engineeringgenetic engineering in biomaterialsimmunogenicity in collagen sourcespathogen-free collagen productionrecombinant human type III collagenregenerative medicine innovationsskin repair techniquestissue engineering applicationswound healing advancements