In the relentless battle against corrosion, a groundbreaking advancement has emerged from the realm of laser technology, promising to revolutionize the durability and longevity of stainless steel surfaces. Researchers Zheng, Zang, Liu, and their team have unveiled a pioneering technique that employs strong-field laser surface passivation to significantly mitigate the corrosive degradation that has long plagued stainless steel. This breakthrough, detailed in their recent publication in Light: Science & Applications, could herald a new era of material resilience across multiple industries, ranging from infrastructure to biomedical devices.

Corrosion, the gradual destruction of materials by chemical or electrochemical reactions with their environment, has been a persistent challenge in engineering and manufacturing. Stainless steel, widely lauded for its inherent corrosion resistance due to its chromium content, is still vulnerable to aggressive environments which can initiate pitting, crevice corrosion, and stress corrosion cracking. Traditional methods of corrosion protection, such as coatings and chemical passivation, often fail to provide a permanent barrier or involve environmentally hazardous substances. The new laser-based approach introduces a paradigm shift by altering the surface characteristics at a microstructural level, thus enhancing resistance intrinsically.

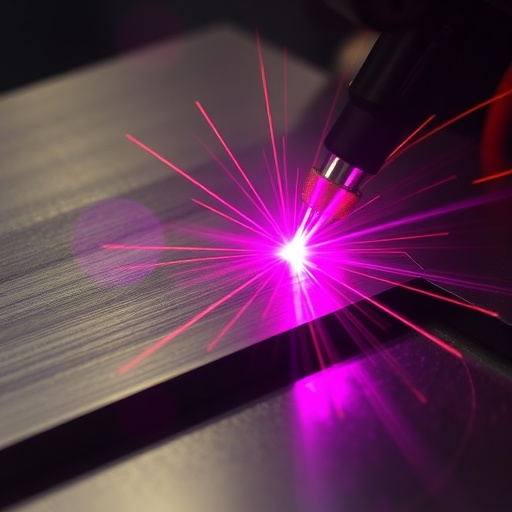

The mechanism behind strong-field laser surface passivation hinges on the precise and controlled application of high-intensity laser pulses to the stainless steel surface. This process induces a series of nonlinear optical and thermal effects that lead to the formation of a dense, uniform oxide layer with superior protective properties compared to naturally occurring passivation layers. Notably, the laser treatment modifies the surface morphology at the nanoscale, eliminating defects and heterogeneities that typically serve as initiation sites for corrosion processes.

One of the remarkable features of this laser technique is its efficiency and environmental benignity. Unlike chemical passivation methods that rely on hazardous agents such as nitric or phosphoric acid, laser passivation is clean, solvent-free, and can be precisely controlled to target specific areas without damaging the bulk material. The pulsed laser application ensures minimal thermal diffusion, preserving the structural integrity and mechanical properties of the stainless steel substrate, while simultaneously creating a robust oxide barrier.

Extensive experimentation by the research team demonstrated a dramatic reduction in corrosion rates—up to an order of magnitude lower than untreated surfaces—when exposed to highly aggressive chloride-containing environments, one of the most common and destructive settings for stainless steel degradation. Electrochemical impedance spectroscopy and potentiodynamic polarization studies confirmed the superior passivation behavior imparted by the laser treatment. Moreover, surface analysis techniques such as scanning electron microscopy and X-ray photoelectron spectroscopy revealed the emergence of a homogeneous, chromium-enriched oxide layer, vital for sustaining long-term corrosion resistance.

This technological breakthrough holds incredible promise for applications in harsh industrial environments such as marine infrastructure, chemical processing plants, and medical implant manufacturing, where stainless steel components are routinely exposed to corrosive agents. By significantly extending the service life of these components, this laser passivation method could reduce maintenance costs, prevent catastrophic failures, and improve safety standards.

Further implications extend to the sustainability domain, as enhancing the corrosion resistance of stainless steel aligns with global efforts to reduce material waste and energy consumption associated with frequent replacements. The scalability of laser surface passivation also demonstrates its potential for seamless integration within existing manufacturing workflows, allowing industries to adopt this technology without disruptive overhauls.

Beyond corrosion mitigation, the insights gained through this research may inspire new avenues in laser surface engineering, underscoring the versatility of ultrafast laser-material interactions to tailor surface properties with unprecedented precision. Researchers speculate that similar methods might be adapted for other alloys and metals prone to environmental degradation, opening a broad spectrum of protective coatings and surface modification strategies.

While the study foregrounds a compelling new tool in combating corrosion, it also lays bare crucial questions for future investigation. For instance, the long-term stability of the laser-induced oxide layer under cyclic mechanical stresses and temperature fluctuations remains to be rigorously evaluated. Additionally, understanding the dynamics of oxide layer regeneration following wear or damage could further optimize this method for real-world operational conditions.

Industrial adoption will depend on balancing the initial costs associated with high-power laser systems against the substantial savings gained from improved durability and reduced downtime. However, as the technology matures and laser hardware becomes more accessible, it is anticipated that strong-field laser passivation will become a cornerstone technology in materials engineering.

Crucially, this innovation represents a harmonious blend of physics, materials science, and engineering, exemplifying how fundamental laser-matter interaction studies can translate into tangible societal benefits. The ability to manipulate surface chemistry and structure on nanometer scales to engineer protective layers without compromising bulk properties reflects a significant leap toward smarter and more sustainable materials.

In conclusion, the work by Zheng, Zang, Liu, and colleagues introduces a transformative laser-based methodology that dramatically curtails corrosion in stainless steel by fostering a robust and uniform passivation layer through strong-field laser interactions. This technique transcends conventional approaches, offering a clean, efficient, and highly effective solution to a pervasive and costly problem. As industries seek to improve reliability and sustainability, such scientific advancements underscore the pivotal role of innovative laser technologies in shaping the next generation of high-performance materials.

Subject of Research:

Article Title:

Article References: Zheng, L., Zang, H., Liu, Y. et al. Significant reduction of corrosion of stainless steel by strong-field laser surface passivation. Light Sci Appl 14, 352 (2025). https://doi.org/10.1038/s41377-025-01952-5

Image Credits: AI Generated

DOI: https://doi.org/10.1038/s41377-025-01952-5

Keywords:

Tags: biomedical device longevitycorrosion mitigation methodsengineering challenges in corrosionenvironmental impact of corrosioninfrastructure material resilienceinnovative corrosion protection solutionslaser surface passivation techniquematerial durability advancementsmicrostructural surface modificationpitting and stress corrosion crackingstainless steel corrosion resistancestrong-field laser technology