In the swiftly evolving landscape of advanced manufacturing, the ability to predict and control temperature distributions during metal additive manufacturing processes is emerging as a critical frontier. Recent research has pioneered an innovative approach that integrates physics-informed machine learning with real-time temperature field predictions, promising to revolutionize how metallic components are fabricated layer by layer. This breakthrough method, unveiled by Tian, Mu, Liu, and colleagues, addresses long-standing challenges associated with monitoring and managing thermal behaviors in metallic additive manufacturing, providing an unprecedented level of precision and foresight in process control.

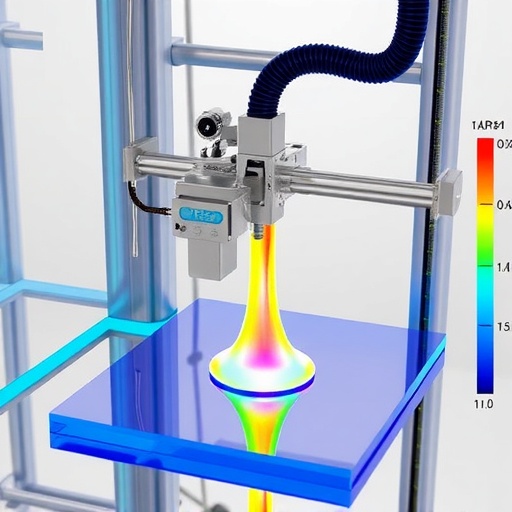

Additive manufacturing, particularly metal-based techniques such as selective laser melting or directed energy deposition, relies heavily on precise thermal management to ensure structural integrity and desired material properties. Traditional thermal monitoring techniques often struggle with the dynamic, rapid heating and cooling cycles inherent in these processes. Equally challenging is the prediction of temperature fields over extended horizons, where small deviations can lead to defects, residual stresses, or undesirable microstructures. The novel framework developed by the research team leverages the synergy between physical laws governing heat transfer and advanced machine learning algorithms, enabling long-horizon predictions far beyond the reach of conventional models.

Central to this research is the concept of physics-informed machine learning (PIML), which effectively blends deterministic physical models with data-driven approaches. Unlike purely empirical models, PIML integrates known physical principles—such as heat conduction equations and phase-change dynamics—into the architecture of neural networks. This fusion allows the system to not only learn from experimental and simulated data but also to inherently respect the underlying physics of heat transfer, leading to predictions that are both robust and interpretable. The technique is particularly well-suited for real-time applications where rapid response and adaptability are paramount.

The researchers designed a physics-informed neural network that captures the temperature evolution within metallic parts as they undergo additive manufacturing. By incorporating partial differential equations related to heat conduction and source terms representing laser inputs, their model can predict temperature changes across the spatial domain and over time. What sets this model apart is its capability to forecast temperature fields over extended periods, a feature referred to as long-horizon prediction. This contrasts with traditional time-stepping methods that are computationally intensive and lack real-time feasibility.

A critical innovation in the work is the seamless coupling of physics-informed constraints with machine learning’s data assimilation strength. This fusion enhances prediction accuracy under conditions of incomplete or noisy sensor information, a common issue in industrial settings. By grounding the learning process in physical laws, the model avoids the pitfalls of overfitting and extrapolation errors that often plague data-driven approaches when operating outside the training data distribution. Consequently, the model maintains fidelity even as process parameters vary, ensuring reliability across different metal types and geometries.

The team validated their framework using extensive datasets collected from thermal sensors embedded within metal additive manufacturing setups. These sensors provided temperature readings that, while limited in spatial coverage, were sufficient when combined with the model’s predictive framework to reconstruct detailed temperature maps. The results demonstrated remarkable agreement between predicted and experimentally measured temperature fields, showcasing not only the model’s accuracy but also its adaptability in handling real-world complexities such as material heterogeneity and heat dissipation pathways.

Beyond accuracy, the model exhibits impressive computational efficiency. By circumventing the need to solve complex partial differential equations numerically at every timestep, the physics-informed machine learning approach significantly reduces computational overhead. This advantage opens the door for integrating the system into closed-loop process control, where rapid feedback and adjustment are essential for maintaining quality and minimizing defects during production.

The implications of this research extend far beyond metallic additive manufacturing. The approach offers a template for applying physics-informed machine learning to other domains characterized by complex thermal dynamics, including welding, casting, and even battery manufacturing. As thermal behavior frequently dictates the performance and longevity of engineered components, the ability to reliably predict temperature fields in real time is a game-changer in diverse industrial processes.

Moreover, the integration of this predictive technology with emerging Industry 4.0 frameworks could lead to unprecedented levels of smart manufacturing. Coupling real-time thermal field predictions with automated control systems enhances manufacturing flexibility and responsiveness, empowering factories to produce components on demand while ensuring consistent quality. This paradigm shift could reduce waste, lower costs, and accelerate innovation cycles in sectors ranging from aerospace and automotive to medical implants.

The researchers also highlight the potential for their physics-informed machine learning models to serve as virtual sensors in environments where physical sensor deployment is challenging or impractical. By extrapolating rich spatial and temporal temperature information from limited input data, the models effectively augment sensor networks, providing comprehensive monitoring capabilities without necessitating extensive hardware investment. This capability is particularly valuable in high-temperature or restricted-access settings where sensor reliability and placement options are constrained.

In tackling the notoriously difficult problem of long-horizon temperature prediction, the authors navigated multiple technical challenges, including the management of cumulative errors and the preservation of physical consistency over extended timescales. Their solution involved clever architectural choices in the neural network and the incorporation of regularization techniques that enforce adherence to conservation laws. These innovations ensure that the model maintains accuracy and stability even as prediction horizons extend into the tens of seconds or beyond, a remarkable achievement for such complex, nonlinear thermal processes.

Looking ahead, this research opens exciting avenues for adaptive manufacturing strategies where process parameters can be dynamically adjusted based on real-time thermal forecasts. Such closed-loop optimization promises to finely tune microstructural evolution, mechanical properties, and dimensional accuracy of printed parts, pushing the boundaries of precision manufacturing. Furthermore, the integration of physics-informed machine learning with multi-physics simulations could ultimately enable the holistic prediction of manufacturing outcomes, connecting thermal profiles with mechanical stress, phase transformations, and residual stress buildup.

As with any cutting-edge technological advancement, challenges remain. The generalizability of the model to diverse alloy systems, varied machine architectures, and complex geometries requires further exploration. Additionally, seamless integration into existing manufacturing workflows demands user-friendly software tools and robust hardware interfaces. Nonetheless, the foundational work by Tian and colleagues represents a significant leap forward in marrying machine intelligence with physical realities to solve real-time monitoring and control problems in additive manufacturing.

The momentum behind physics-informed machine learning continues to grow, driven by the confluence of expanding computational power, improved sensor technologies, and urgent industrial needs. This research exemplifies how the synergy between domain knowledge and machine learning can surmount obstacles that neither approach could tackle alone. By delivering accurate long-horizon predictions of temperature fields in metallic additive manufacturing, the study stands to catalyze a new era of precision, efficiency, and adaptability in industrial production.

In summary, this groundbreaking work delineates a future where additive manufacturing processes are not only monitored but anticipated with remarkable accuracy, leading to unprecedented control over materials at the microscale. The fusion of physics and machine learning transforms thermal management from a reactive challenge into a proactive tool, empowering manufacturers to unlock new levels of performance and innovation. As the field progresses, such interdisciplinary advances will undoubtedly reshape the fabric of manufacturing technologies and set new standards for quality, reliability, and sustainability in engineered materials.

Subject of Research:Real-time long-horizon temperature field prediction in metallic additive manufacturing using physics-informed machine learning.

Article Title:Physics-informed machine learning-based real-time long-horizon temperature fields prediction in metallic additive manufacturing.

Article References:

Tian, M., Mu, H., Liu, T. et al. Physics-informed machine learning-based real-time long-horizon temperature fields prediction in metallic additive manufacturing. Commun Eng 4, 168 (2025). https://doi.org/10.1038/s44172-025-00501-7

Image Credits: AI Generated

Tags: advanced manufacturing technologieschallenges in thermal monitoringdirected energy deposition methodslong-horizon temperature predictionsmetal additive manufacturing advancementsphysics-informed machine learning applicationsprocess control in additive manufacturingreal-time temperature predictions in 3D printingselective laser melting processesstructural integrity in 3D printingtemperature field prediction techniquesthermal management in metal printing